A heat pump unit using a secondary heat exchanger

A technology of two-stage heat exchanger and heat pump unit, which is applied in the field of heat pump, can solve the problems that heat conduction and heat conduction are easy to interact with each other, and reduce the heat exchange efficiency of heat pump units, so as to achieve good heat exchange effect, reduce pressure and compressor load, and improve the overall The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

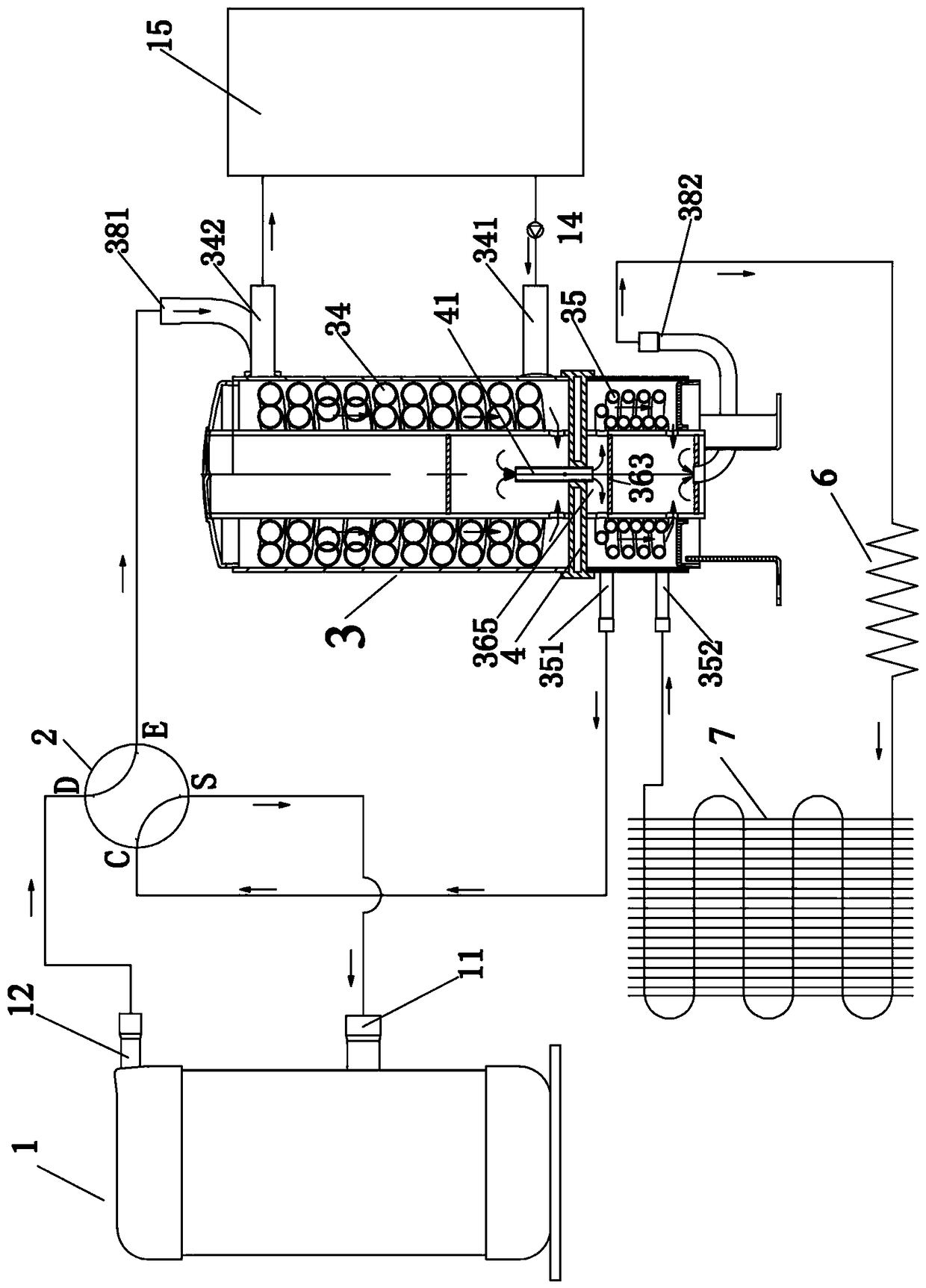

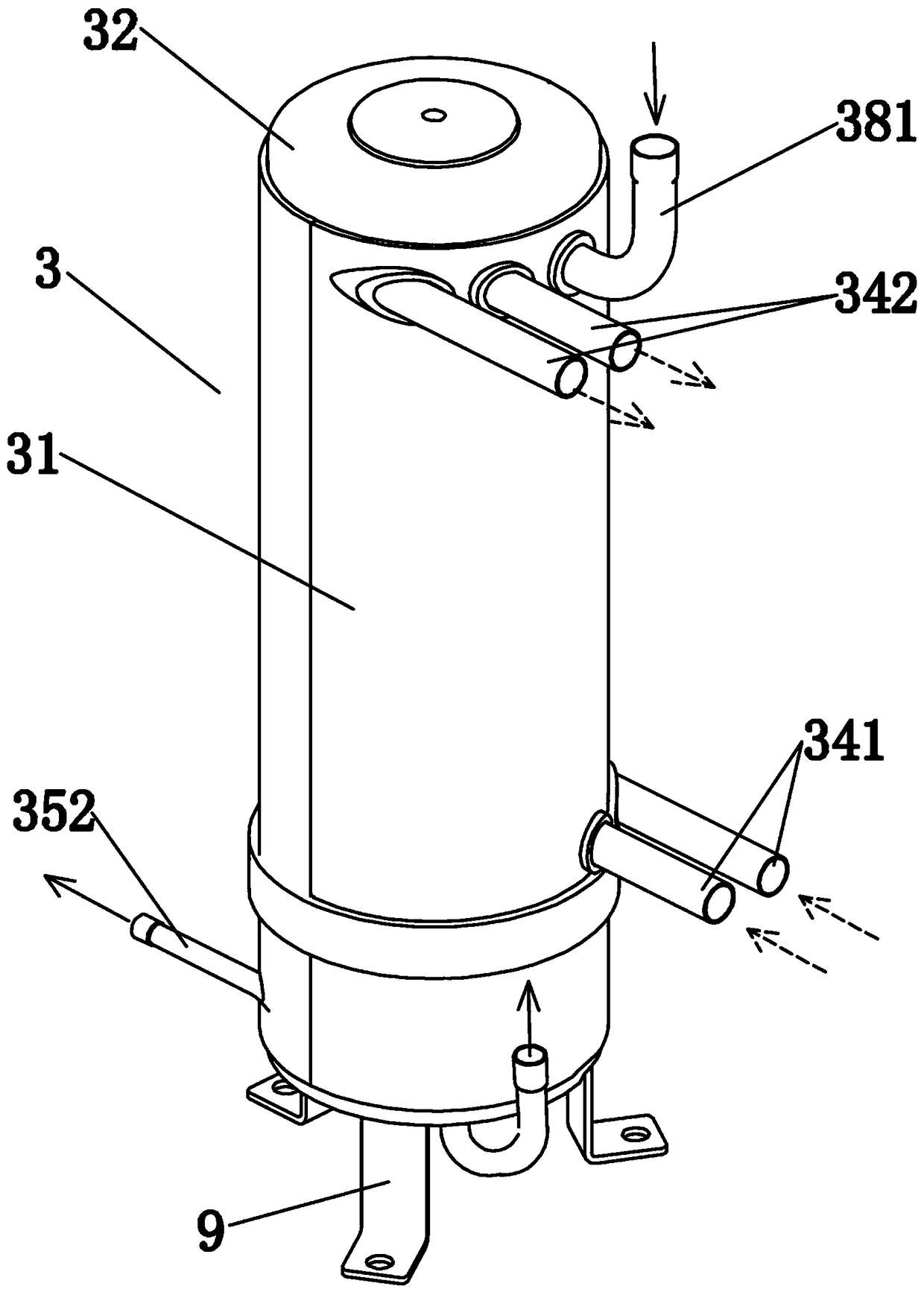

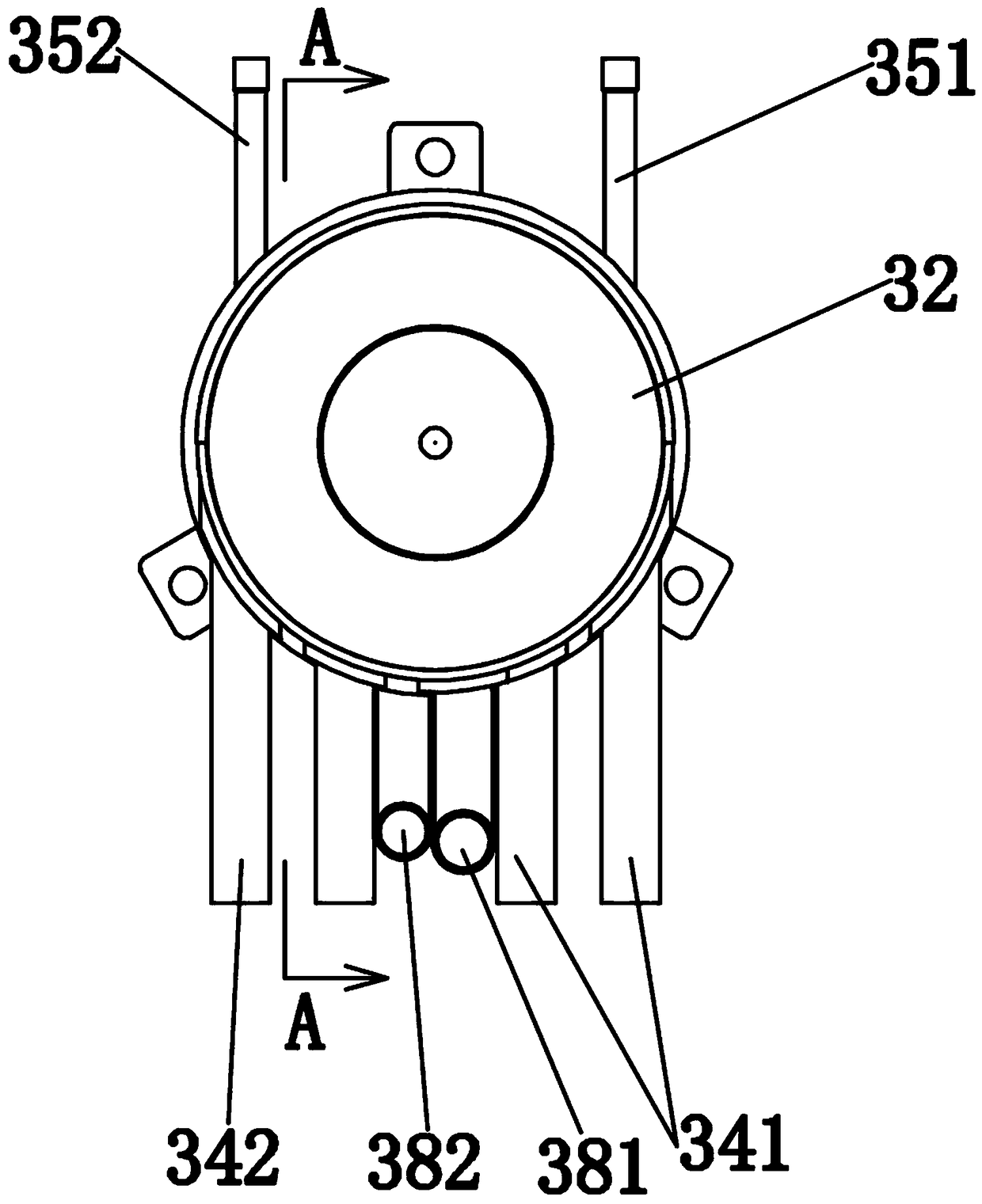

[0035] Example one, as Figure 1 to Figure 5 As shown, a heat pump unit includes a water storage tank 15 and a refrigerant circulation loop formed by connecting a compressor 1, a four-way valve 2, a secondary heat exchanger 3, a first throttling device 6, and a second heat exchanger 7 through pipes , the secondary heat exchanger 3 includes a shell 31, and the shell 31 is divided into a primary heat exchange cavity 38 and a secondary heat exchange cavity 39 by a partition plate 4, and the primary heat exchange cavity 38 and the secondary heat exchange cavity 39. The heat exchange cavity 39 is provided with a primary heat exchange tube 34 and a secondary heat exchange tube 35 respectively, and a communication channel 41 is provided on the partition plate 4, and the communication channel 41 communicates with the primary heat exchange cavity 38 and the secondary heat exchange. Cavity 39.

[0036] The shell 31 is provided with a first refrigerant inlet 381 and a first refrigerant ...

Embodiment 2

[0066] Example two, as Image 6 As shown, the second embodiment is similar to the embodiment of the first embodiment, and the working principle is also the same. The only difference is that the first refrigerant outlet 382 of the secondary heat exchanger 3 passes through the first throttling device 6 and the second One end of the heat exchanger 7 is connected, and the other end of the second heat exchanger 7 is connected to the C interface of the four-way valve 2. The first refrigerant outlet 382 of the secondary heat exchanger 3 is connected to the secondary exchange through the first throttling device 61. The second refrigerant inlet 352 of the heat exchanger 3 is connected, the second refrigerant outlet 351 of the secondary heat exchanger 3 is connected to the C port of the four-way valve 2 , and the S port of the four-way valve 2 is connected to the air return port 11 of the compressor 1 .

[0067] It can be seen from the above that after the liquid refrigerant comes out o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com