High oil-absorbing polyacrylonitrile hollow activated carbon fiber and preparation method thereof

A technology of activated carbon fiber and polyacrylonitrile, which is applied in the manufacture of hollow filaments, chemical instruments and methods, and other chemical processes. It can solve the problems of high production process cost, low reuse rate, and complex production equipment, and achieve oil absorption. Thorough recovery, high oil absorption ratio, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

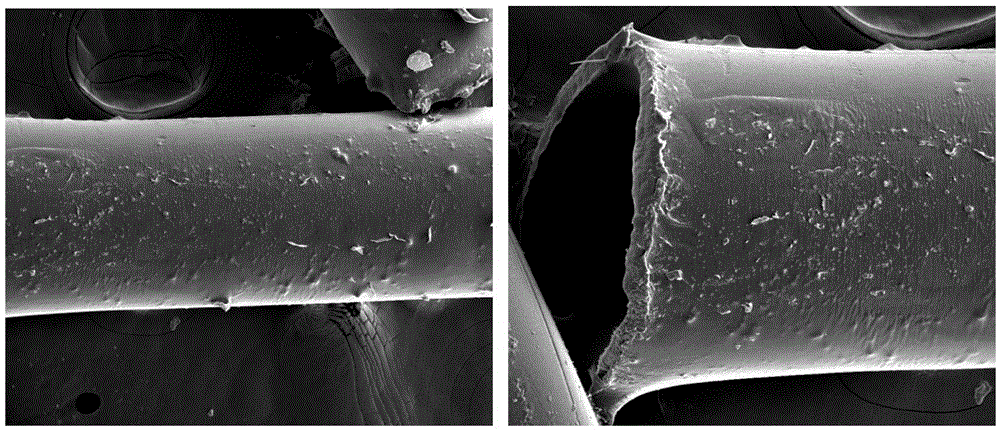

Image

Examples

Embodiment 1

[0031] (1) Preparation of polyacrylonitrile hollow fiber: Dissolve 250 grams of polyacrylonitrile in 750 grams of DMF (N,N-dimethylformamide), stir at 60-80°C to form 25% (mass ratio) The polyacrylonitrile / DMF solution was vacuum-degassed for 6 hours, then allowed to stand for 24 hours, and then dry-wet spinning was carried out at 60°C through an inserted spinneret. The core liquid is pure water, the distance between the spinneret and the coagulation liquid is 20cm, the coagulation liquid is a mixture of solvent and water (DMF: water = 1:1, mass ratio), and the stretching speed is 100 m / min. The nascent polyacrylonitrile hollow fiber was obtained by the above dry-wet method, and then washed with pure water to remove the solvent, and then, after being washed with ethanol, dried at 80°C to form a polyacrylonitrile hollow fiber. The inner diameter of the prepared hollow fiber was 0.3mm, 0.5mm outer diameter.

[0032] (2) The polyacrylonitrile hollow fiber is woven into a net wit...

Embodiment 2

[0044] (1) Preparation of polyacrylonitrile hollow fiber: Dissolve 250 grams of polyacrylonitrile in 750 grams of DMF (N,N-dimethylformamide), stir at 60-80°C to form 25% (mass ratio) The polyacrylonitrile / DMF solution was vacuum-degassed for 6 hours, then allowed to stand for 24 hours, and then dry-wet spinning was carried out at 60°C through an inserted spinneret. The core liquid is pure water, the distance between the spinneret and the coagulation liquid is 20 cm, the coagulation liquid is a mixture of solvent and water (DMF: water = 1:1, mass ratio), and the stretching speed is 120 m / min. The nascent polyacrylonitrile hollow fiber was obtained by the above dry-wet method, and then washed with pure water to remove the solvent, and then, after being washed with ethanol, dried at 80°C to form a polyacrylonitrile hollow fiber. The inner diameter of the prepared hollow fiber was 0.2mm. 0.4mm outer diameter.

[0045] (2) The polyacrylonitrile hollow fiber is woven into a net wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com