Method for lowering fusing temperature of coal ash

A melting temperature and coal ash technology, which is applied in the petroleum industry, solid fuel, fuel additives, etc., can solve the problems of failing to reduce the melting temperature of coal ash, unspecified dosage range, complicated production process, etc., to increase the cost of raw materials, The effect of wide applicability and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Using Maiduoshan (MDS coal) used in liquid coal-water slurry gasification for liquid slagging in Ningxia area as raw coal, according to the method of reducing the melting temperature of coal ash of the present invention, including the step of adding a flux to the raw coal ,Methods as below:

[0040] (1) Obtain effective samples in batches from MDS coal, and grind and ash some coal samples of each batch to obtain MDS standard coal ash samples of each batch;

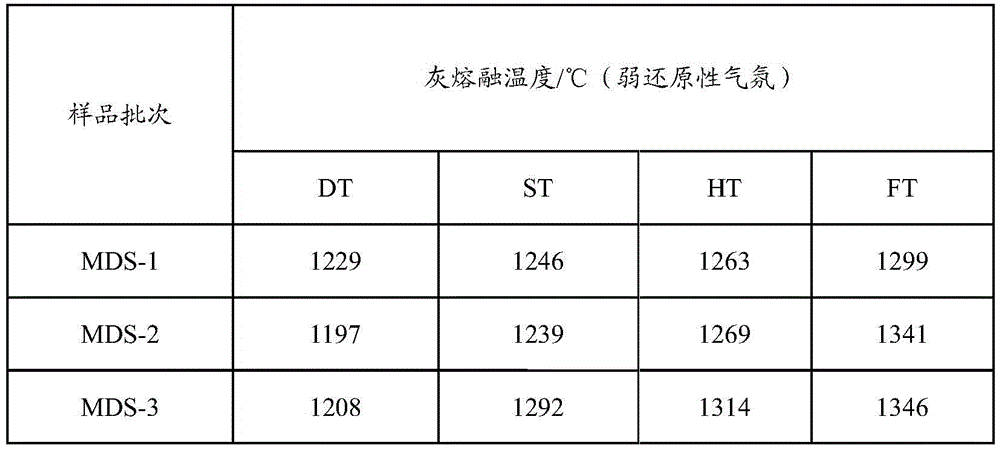

[0041] In addition, in order to verify whether the method of the present invention can reduce the coal ash fusion temperature of MDS coal, the inventor also measured the ash fusion temperature of each batch of MDS standard coal ash samples, that is, respectively obtained the deformation temperature of each batch of standard coal ash samples (DT), softening temperature (ST), hemispherical temperature (HT) and flow temperature (FT). The specific data are shown in Table 1:

[0042] Table 1 Ash melting temperature of ...

Embodiment 2

[0059] Select the MDS standard coal ash sample of the MDS-2 batch among the embodiment 1 to carry out flux addition (the ash content of this batch coal sample is about 15%), select CaO as flux, test according to the following steps:

[0060] a) Grind the MDS standard coal ash sample of the MDS-2 batch to obtain a coal ash sample, divide it into 4 parts, add CaO (powder particle size less than 0.2mm) to each part of coal ash and mix evenly, and each part of coal ash The amount of CaO added increases successively with the amount of 10wt% of the weight of coal ash, that is, the amount of CaO added is respectively 10wt%, 20wt%, 30wt%, 40wt% of each part of coal ash mass (that is, the amount of CaO is the raw coal mass 1.5wt%, 3wt%, 4.5wt%, 6wt%) of each test coal ash sample 1-4 (abbreviated sample 1-4);

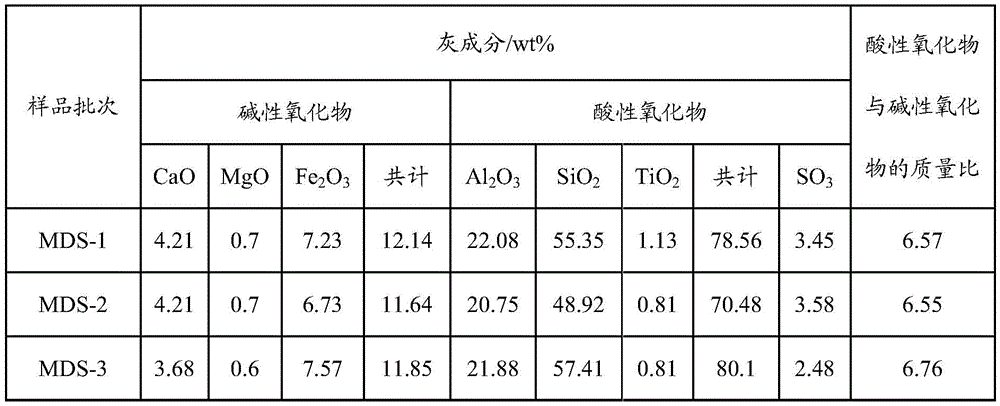

[0061] b) Measure the contents of acidic oxides and basic oxides in samples 1-4 respectively, and calculate the mass ratio of acidic oxides and basic oxides in each sample, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com