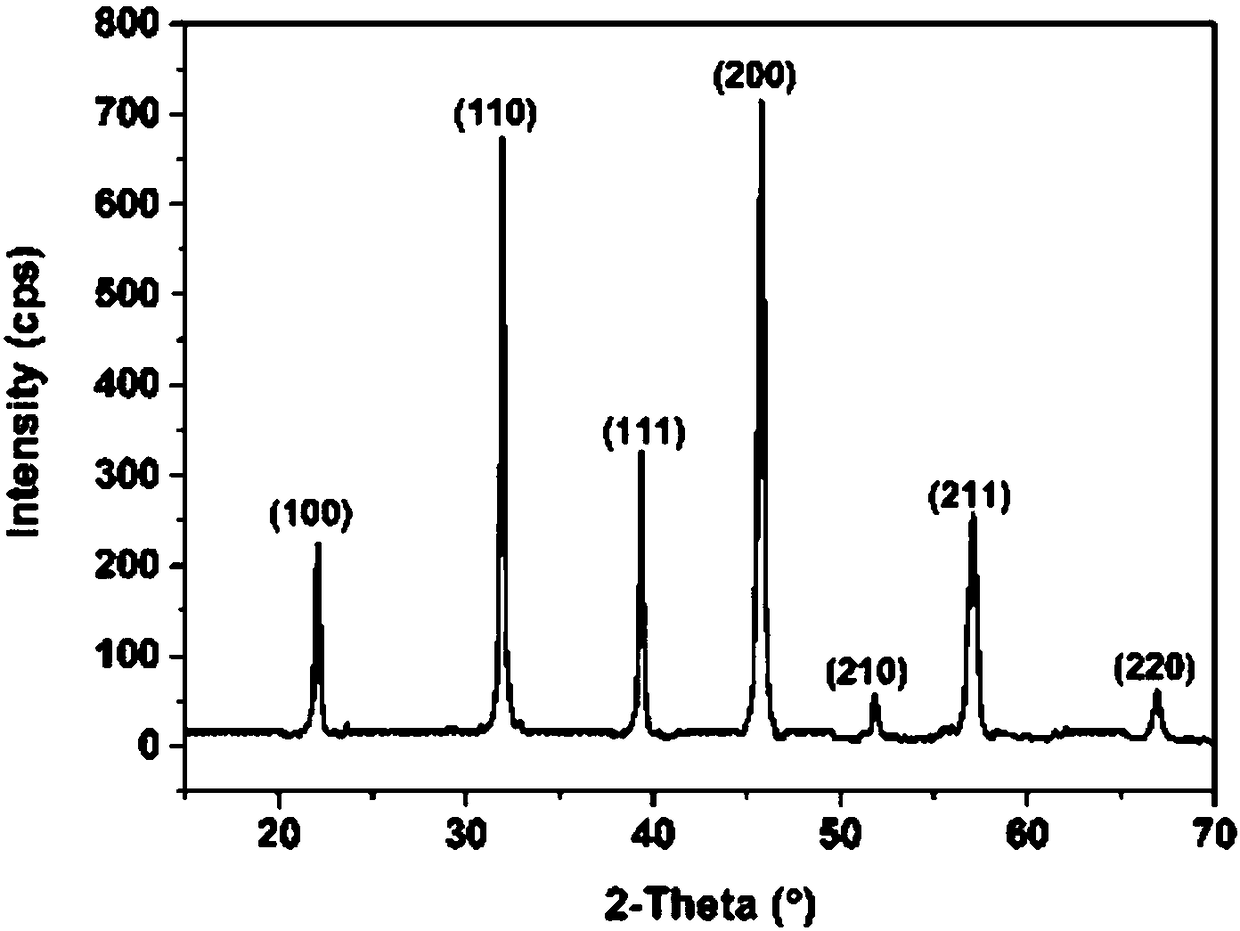

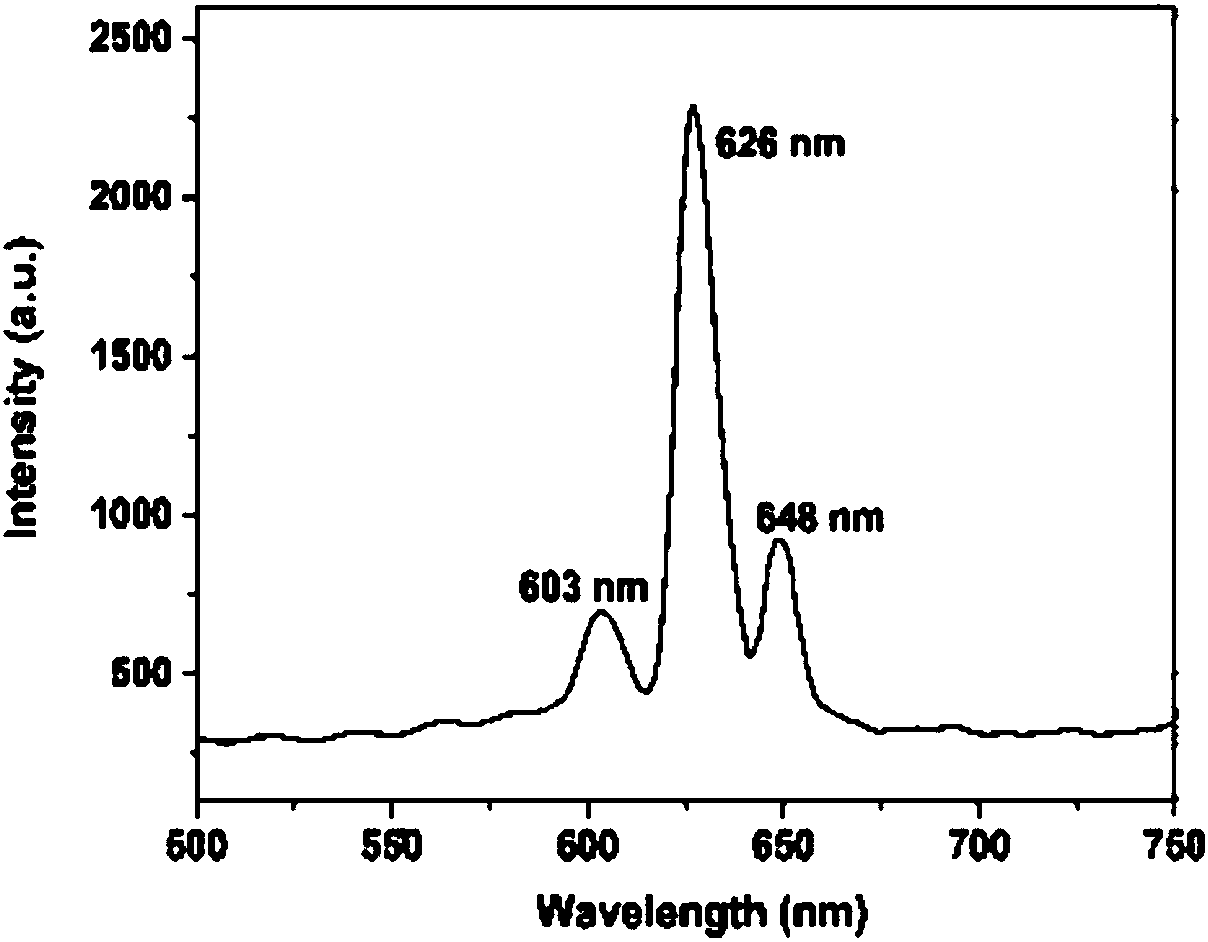

A preparation method of mxsr1-xtio3:eu3+ high-purity red phosphor for high color gamut LED

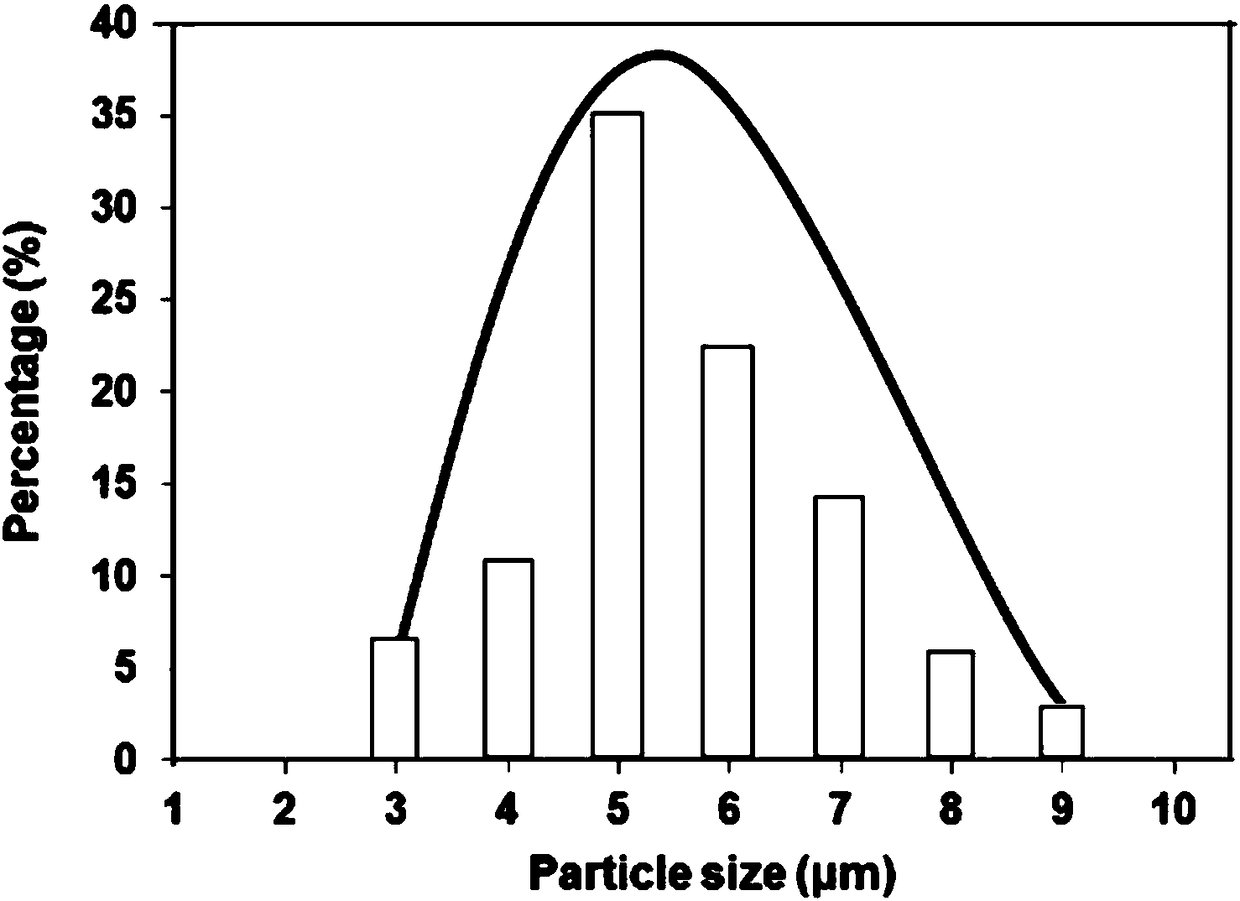

A red light phosphor, SO4 technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of uneven mixing of activators, low color purity of red light, and uneven particle size of phosphor particles. , to achieve the effect of uniform particle size distribution, high red color purity, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 This embodiment discloses a kind of M x Sr 1-x TiO 3 : Eu 3+ The preparation method of high-purity red fluorescent powder, the specific steps are as follows:

[0031] (1) According to the molar ratio of Ca:Sr:Ti=0.2:0.8:1, weigh 0.395g of CaCO 3 Powder, 2.126g of Sr(OH) 2 ·8H 2 O and 4.021g of Ti(SO 4 ) 2 9H 2 O. According to Eu 3+ The molar concentration is 4mo% (referring to Eu 3+ Accounted for matrix material Ca 0.2 Sr 0.8 TiO 3 molar concentration), weigh 0.070g of Eu 2 o 3 Powder.

[0032] (2) the CaCO in step 1) 3 , Sr(OH) 2 ·8H 2 O, Ti(SO 4 ) 2 9H 2 O and Eu 2 o 3 Put the powder together in 100mL of 30% HNO 3 In solution, incubate at 50°C for 90 minutes to obtain clear Ca 2+ 、Sr 2+ 、Ti 4+ and Eu 3+ mixture.

[0033] (3) According to C 6 h 8 o 7 (citric acid): the molar ratio of Ti=2.25:1, weigh 4.728g of C 6 h 8 o 7 ·H 2 O is placed in the solution of step 2), and then the solution is placed on a magnetic stirrer,...

Embodiment 2

[0037] Embodiment 2 This embodiment discloses a M x Sr 1-x TiO 3 : Eu 3+ The preparation method of high-purity red fluorescent powder, the specific steps are as follows:

[0038] (1) According to the molar ratio of Mg: Ba: Sr: Ti = 0.1: 0.4: 0.5: 1, weigh 0.040 g of MgO, 0.789 g of BaCO 3 Powder, 1.329g of Sr(OH) 2 ·8H 2 O and 4.021g of Ti(S O 4 ) 2 9H 2 O. According to Eu 3+ The molar concentration is 1mol% (referring to Eu 3+ Accounting for matrix material Mg 0.1 Ba 0.4 Sr 0.5 TiO 3 molar concentration), weigh 0.018g of Eu 2 o 3 Powder.

[0039] (2) MgO, BaCO in step 1) 3 , Sr(OH) 2 ·8H 2 O, Ti(SO 4 ) 2 9H 2 O and Eu 2 o 3 Put the powder together in 100mL of 30% HNO 3 solution at 70°C for 45 minutes to obtain clear Mg 2+ 、Ba 2+ 、Sr 2+ 、Ti 4+ and Eu 3+ mixture.

[0040] (3) According to C 6 h 8 o 7 (citric acid): the ratio of Ti=3.2:1, weigh 6.724g of C 6 h 8 o 7 ·H 2 O is placed in the solution of step 2), and then the solution is plac...

Embodiment 3

[0044] Embodiment 3 This embodiment discloses a M x Sr 1-x TiO 3 : Eu 3+ The preparation method of high-purity red fluorescent powder, the specific steps are as follows:

[0045] (1) According to the molar ratio of Zn:Sr:Ti=0.05:0.95:1, weigh 0.041g of ZnO powder, 2.525g of Sr(OH) 2 ·8H 2 O and 4.021g of Ti(SO 4 ) 2 9H 2 O. According to Eu 3+ The molar concentration is 0.2mol% (referring to Eu 3+ Accounted for matrix material Zn 0.05 Sr 0.95 TiO 3 molar concentration), weigh 0.004g of Eu 2 o 3 Powder.

[0046] (2) ZnO, Sr(OH) in step 1) 2 ·8H 2 O, Ti(SO 4 ) 2 9H 2 O and Eu 2 o 3 Put the powder together in 100mL of 30% HNO 3 solution, at 70°C for 40 minutes to obtain clear Zn 2+ 、Sr 2+ 、Ti 4+ and Eu 3+ mixture.

[0047] (3) According to C 6 h 8 o 7 (citric acid): Ti=3.8:1 ratio, weigh 7.985g of C 6 h 8 o 7 ·H 2 O is placed in the solution of step 2), and then the solution is placed on a magnetic stirrer, and the magnetic rotor speed is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com