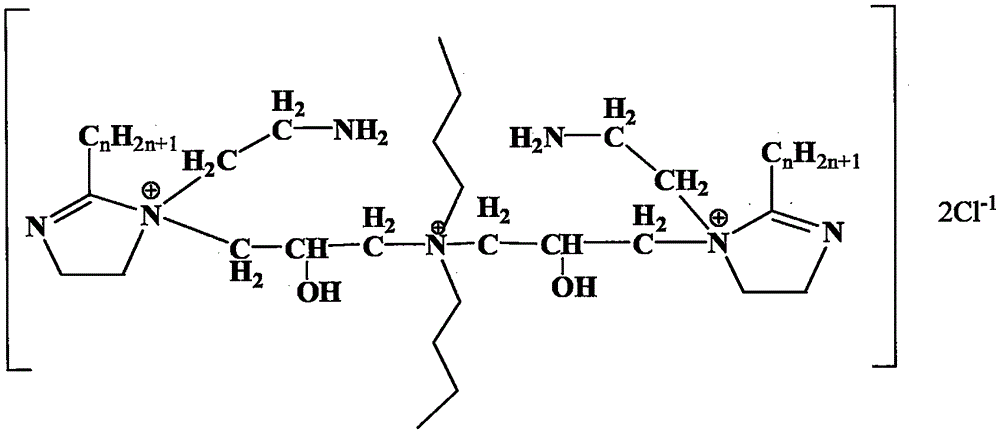

Gemini imidazoline-ammonium-salt and preparation method and application thereof

A technology of gemini imidazoline and quaternary ammonium salt is applied in the field of asphalt emulsifier for rapid opening traffic type slurry seal and its preparation, which can solve the problems of poor slow cracking and fast setting effect, high cost, unstable raw material source and the like , to achieve the effect of improving water solubility and emulsifying properties, low production cost and good emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, using capric acid and ethylenediamine with a molar ratio of 1:1 as raw materials, add toluene accounting for 20% of the total weight of the reaction materials, stir and heat up to 140°C, and react at a constant temperature for 4h; raise the temperature to 220°C under vacuum. ℃ as the raw material, continue the reaction for 2h to remove the solvent and water, and obtain the imidazoline matrix. Then, take dimethylamine and epichlorohydrin as raw materials with a molar ratio of 1: 2.0, add ethanol accounting for 30% of the total weight of the reaction mass, add dropwise hydrochloric acid in the same molar amount as epichlorohydrin in the reaction system, and stir Raise the temperature to 20°C, react at a constant temperature for 12h, remove the solvent and unreacted materials, and obtain N-butyl-N,N-di(3-chloro-2-hydroxypropyl)butane-1-ammonium salt (intermediate ). Finally, using the imidazoline matrix and intermediates with a molar ratio of 2:1 as raw materials, ...

Embodiment 2

[0031] First, using lauric acid and hydroxyethylethylenediamine with a molar ratio of 1:2 as raw materials, add m-xylene accounting for 50% of the total weight of the reaction material, stir and heat up to 180 ° C, and react at a constant temperature for 2 hours; Raise the temperature to 260°C as the raw material, continue the reaction for 6h to remove the solvent and water, and obtain the imidazoline matrix. Then, be 1: 3.0 diethylamine and epichlorohydrin as raw material with molar ratio, add the propanol that accounts for 50% of reaction mass gross weight, drip the hydrochloric acid of the same molar quantity as epichlorohydrin in reaction system, Stir and heat up to 60°C, react at a constant temperature for 8 hours, remove the solvent and unreacted materials, and obtain N-butyl-N,N-bis(3-chloro-2-hydroxypropyl)butane-1-ammonium salt (intermediate body). Finally, using the imidazoline matrix and intermediates with a molar ratio of 3:1 as raw materials, add butanol accounti...

Embodiment 3

[0037] First, using tetradecanoic acid and diethylenetriamine with a molar ratio of 1:1.5 as raw materials, add o-xylene accounting for 30% of the total weight of the reaction materials, stir and heat up to 150 ° C, and react at a constant temperature for 3 hours; High temperature to 230°C is used as raw material, and the reaction is continued for 3 hours to remove solvent and water to obtain imidazoline matrix. Then, take dipropylamine and epichlorohydrin as raw materials with a molar ratio of 1: 2.5, add butanol accounting for 40% of the total weight of the reaction mass, add dropwise hydrochloric acid in the same molar amount as epichlorohydrin in the reaction system, and stir Raise the temperature to 30°C, react at a constant temperature for 9h, remove the solvent and unreacted materials, and obtain N-butyl-N,N-di(3-chloro-2-hydroxypropyl)butane-1-ammonium salt (intermediate ). Finally, using the imidazoline matrix and intermediates with a molar ratio of 2.5:1 as raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com