Inorganic high-performance thin-wall sound barrier for transportation

A high-performance, sound barrier technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of weak sound insulation effect and reduced sound insulation, and achieve fast and convenient construction and installation, weight reduction, Create handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

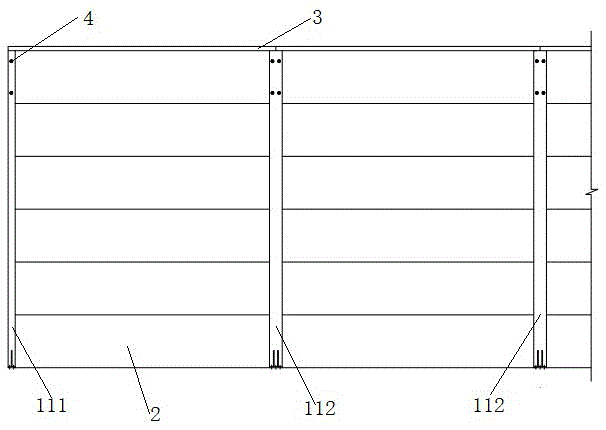

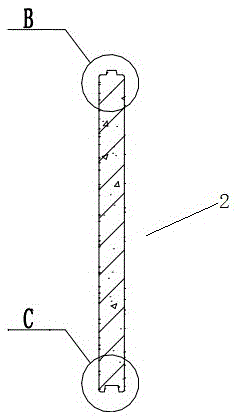

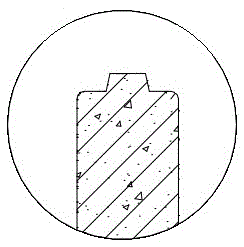

[0055] Such as figure 1 The inorganic high-performance thin-walled sound barrier for transportation includes a plurality of columns and a plurality of wall panels 2 connected up and down between adjacent columns, and the topmost wall panel is provided with a pressure top 3 . The column includes side columns 111 arranged at the left and right ends and a plurality of central columns 112 arranged between the side columns 111, such as Figure 5 and 6 As shown, one end of the side column 111 and the left and right ends of the center column 112 are provided with slots for placing the wall panels 2 . Such as Figure 8 As shown, the top pressing 3 is provided with a slot 311 adapted to the convex groove of the topmost wallboard. Such as figure 2 , 3 As shown in and 4, the upper and lower ends of the wallboard 2 are respectively provided with grooves and convex grooves, the grooves are spliced correspondingly with the convex grooves of adjacent wallboards, and the convex groove...

Embodiment 2

[0071] Except that the composition and preparation method of the wallboard and the top are not consistent with Example 1, other conditions are the same as Example 1.

[0072] The wallboard and the top are poured with the following raw materials in parts by weight:

[0073] Grades with an average particle size of 30-60 μm shall not be lower than 500 parts of 42.5 cement;

[0074] 300 parts of active admixtures with an average particle size of 0.1~10 μm and a SiO2 content of ≥85%;

[0075] 1600 parts of river sand aggregate with a particle size of 0.16~0.63mm

[0076] 16 parts of high-efficiency water reducing agent with water reducing rate greater than 30%;

[0077] 160 parts of water;

[0078] 15 parts of PVA fiber with a length of 8-12 mm;

[0079] 40 parts of basalt fiber with a length of 10~14mm.

[0080] The active admixture includes ultrafine ceramic sludge powder, silica fume and fly ash, and the ratio of the three is 4:4:1.

[0081] The preparation method is as fo...

Embodiment 3

[0087] 400 parts of cement removal, 230 parts of active admixture, 1450 parts of river sand aggregate, 13 parts of superplasticizer, 130 parts of water, 8 parts of PVA fiber, 25 parts of basalt fiber, superfine ceramic silt powder: silica fume: powder Coal ash=2:2:1, other conditions are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com