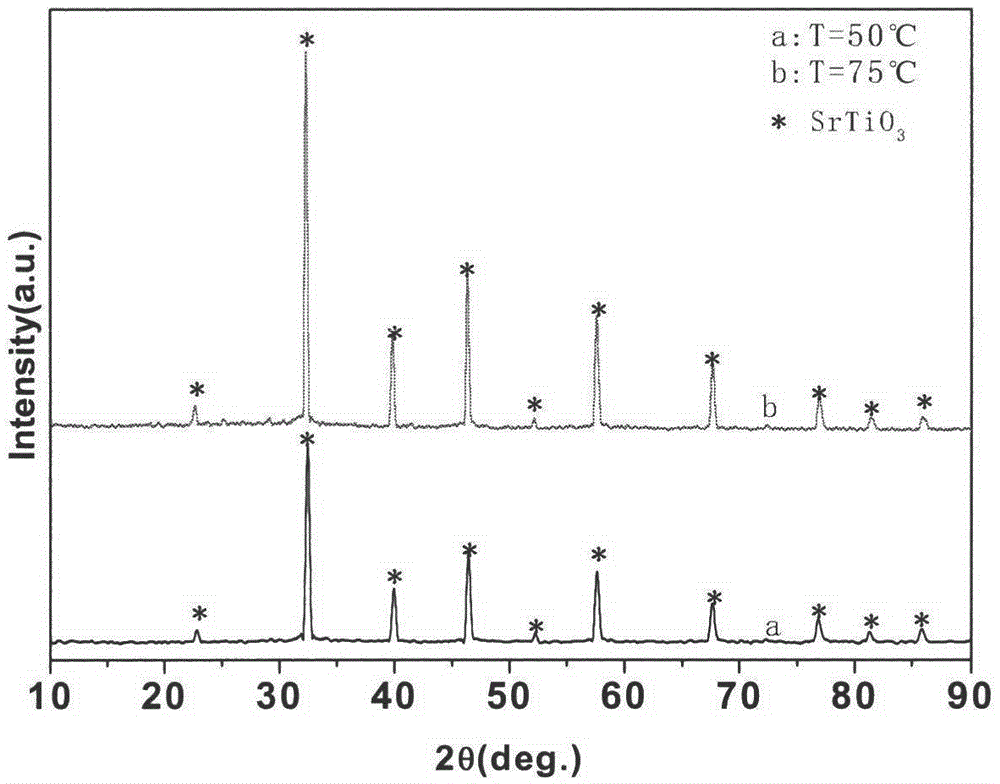

Low-temperature direct-precipitation preparation method of sub-micron grade strontium titanate

A sub-micron strontium titanate technology, applied in the direction of titanate, alkaline earth metal titanate, chemical instruments and methods, can solve the problems of hard agglomeration and increase the cost of exhaust gas recovery, and achieve fine and uniform particle size, low cost Low cost and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

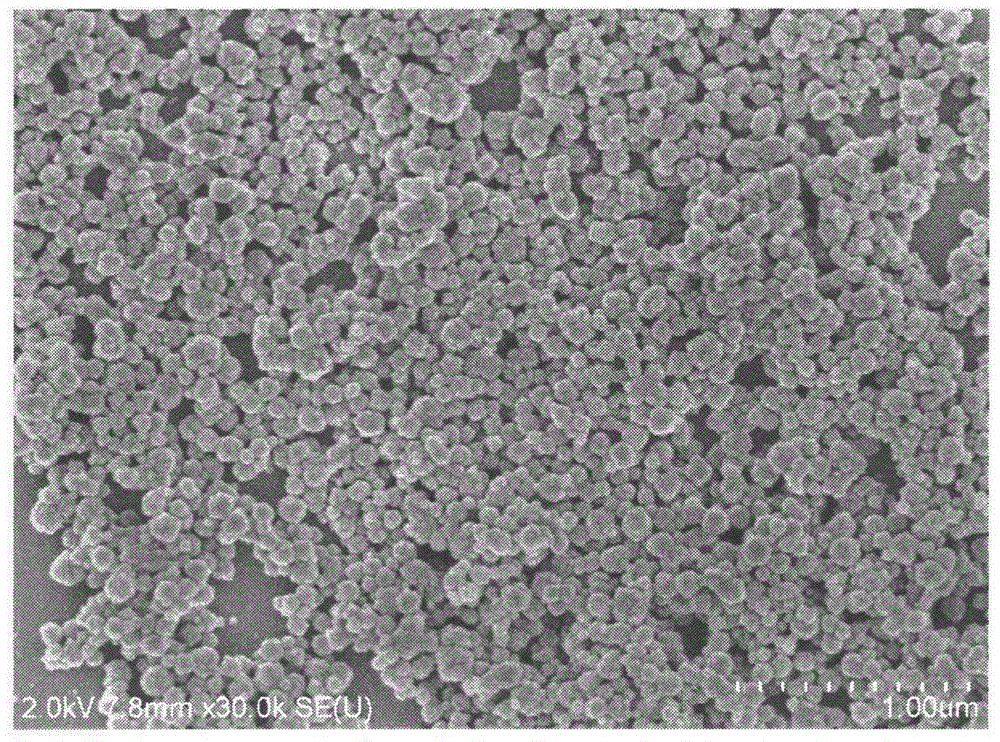

Embodiment 1

[0021] Measure the prepared 1.2mol / L SrCl with a graduated cylinder 2 solution (19.8mL) and 1.2mol / L of TiCl 4 solution (18mL), that is, the molar ratio of strontium ions and titanium ions is 1.1: 1 and stirred and mixed evenly, then PEG4000 is added to the system as a dispersant (wherein the amount of PEG4000 added is SrTiO 3 0.5% of theoretical output) fully stirred; Add 6mol / L NaOH solution 22mL in above-mentioned mixed solution, guarantee that the pH=13 of suspension liquid after reaction finishes; The feed liquid that will mix is added to be placed in the constant temperature water bath In the three-necked flask, one of the side ports on both sides of the three-necked flask is equipped with a thermometer sleeve and a thermometer, and the other is equipped with a serpentine reflux condenser. Use an electric mixer as the stirring device, adjust the speed of the electric mixer to 250r / min, and raise the temperature to 50°C. Time starts counting, and after 4 hours, turn of...

Embodiment 2

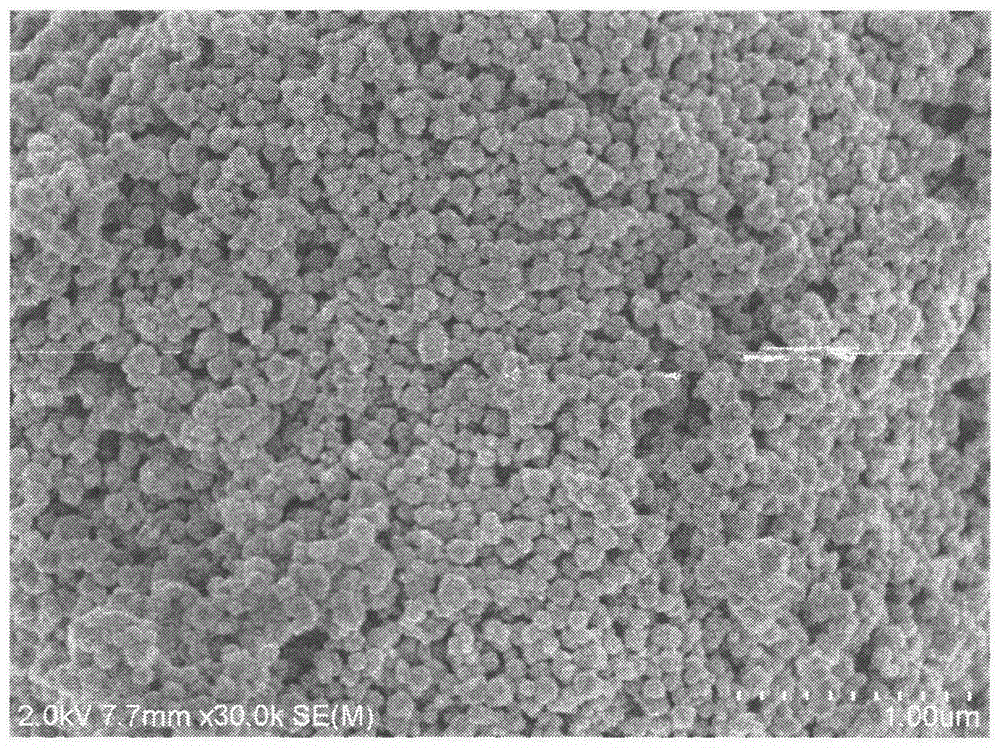

[0026] Carry out according to the method in embodiment 1, reaction temperature is 75 ℃, and difference is that dispersant adopts PEG2000 (wherein the addition of PEG2000 is SrTiO 3 0.5% of theoretical yield).

[0027] image 3 It is the SEM of the product obtained in Example 2. It can be seen from the figure that when the strontium titanate powder is prepared by the low-temperature direct precipitation method, adding PEG2000 as a dispersant can improve the agglomeration of the powder, but the effect is not as good as that of PEG4000, and the shape is a regular spherical shape. , the distribution and size are uniform, the shape is cubic phase, the particle size of the powder is small, most of them are around 60nm, which is similar to the XRD calculation result, and the particle size has reached the nanometer level.

Embodiment 3

[0029] The raw strontium chloride solution was made from SrCO 3 (AR) and hydrochloric acid solution reaction system. Accurately weigh 3.51gSrCO 3 , the weighed SrCO 3 Put it into the beaker; then slowly add the dilute hydrochloric acid solution into the beaker until no more bubbles are generated; use a graduated cylinder to measure the prepared 1.2mol / L TiCl 4 solution (18mL), that is, the molar ratio of strontium ion and titanium ion is 1.1: 1, stir and mix evenly, fully stir; add 22mL of 6mol / L NaOH solution to the above mixed solution to ensure that the pH of the suspension after the reaction is finished=13 ; Add the mixed material liquid into the three-necked flask placed in the constant temperature water bath, use the electric mixer as the stirring device, adjust the speed of the electric mixer to 250r / min, start timing when the temperature rises to 75°C, and turn off the constant temperature water bath after 4h and an electric mixer, stand still for 0.5h, and carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com