Gas treatment device of organic waste cracking furnace

A technology for organic waste and gas treatment, applied in the field of optimization systems, can solve problems such as equipment and environmental hazards, and achieve the effects of fast neutralization, enhanced mass transfer, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

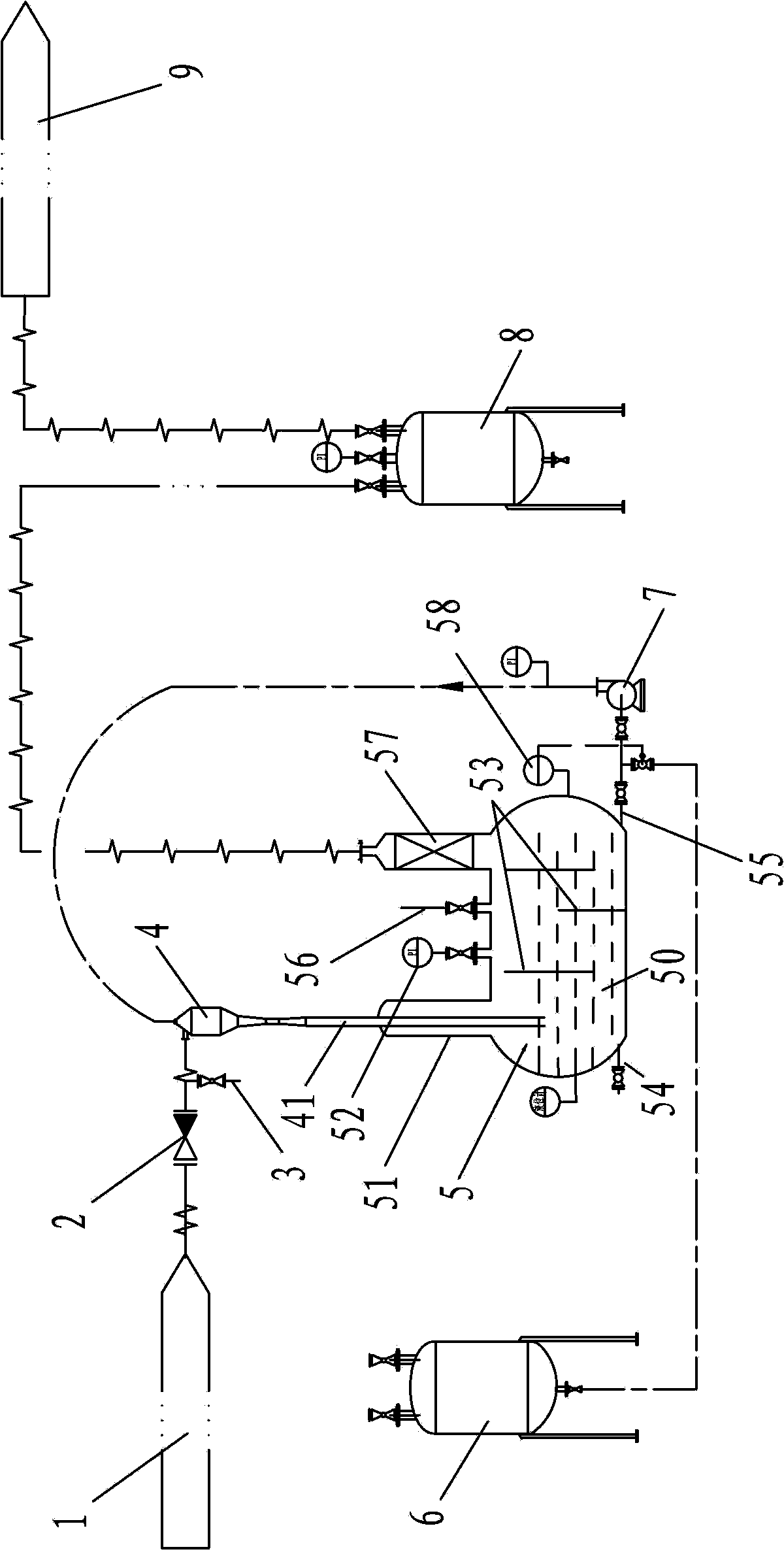

[0032] For specific embodiments of the present invention, refer to figure 1 , the gas treatment device of the organic waste pyrolysis furnace, including a gas-liquid mixing chamber 4, a multi-functional separator 5, a liquid circulation device and a gas storage tank 8 and so on. The details are as follows:

[0033] The organic waste is sent to the cracking furnace through the feeding system, and after being heated by the combustion system, the gas phase is condensed through the gas-solid separator, rectification tower, and condensation system (not shown in the above process diagram), and the non-condensable gas without condensation 1 passes through The spray mixing chamber 4 entered by the return valve 2 is mixed, and then enters the multifunctional separator 5 through the connecting pipe 41 ; wherein, an emptying port 3 is also provided between the spray mixing chamber 4 and the check valve 2 . The hydrogen chloride contained in the mixing chamber 4 is neutralized to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com