Method for preparing electrode material of supercapacitor from mimosa pudica

A technology for supercapacitors and electrode materials, applied in the field of electrochemistry, to achieve the effects of mild reaction conditions, good repeatability, and rapid growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

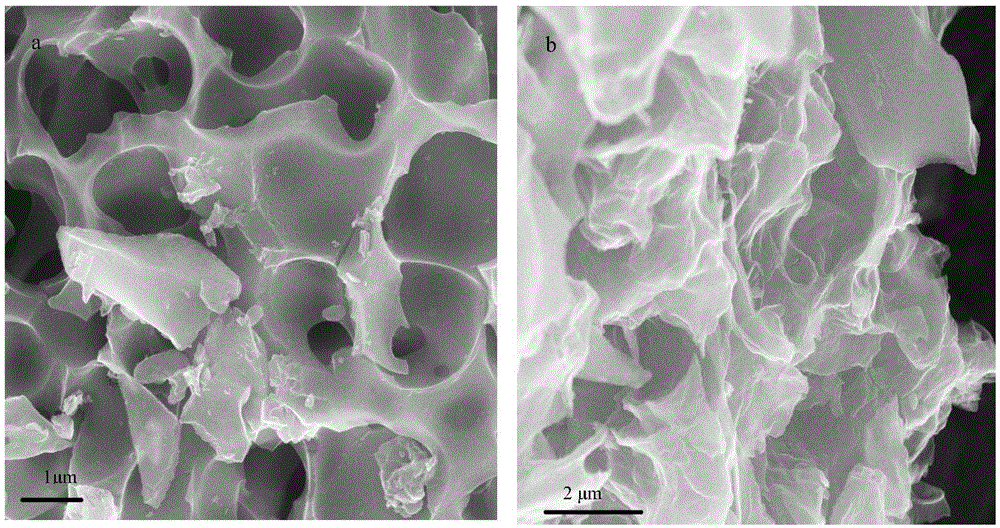

Image

Examples

Embodiment 1

[0023] 15g of cut fresh mimosa were washed 3 times with absolute ethanol and deionized water, and then placed in a vacuum freeze dryer for 24 hours at a vacuum degree of 4.0Pa and at -103°C for lyophilization. Put the mimosa in a quartz boat and put it into a tube furnace. Under the protection of argon, first raise the temperature to 200°C at a heating rate of 5°C / min, carbonize at a low temperature for 1 hour, then raise the temperature to 800°C, and carbonize at a high temperature for 3 hours. After it was cooled to room temperature, the carbonized product was taken out, ground into powder, washed three times with absolute ethanol, and dried in an oven at 60°C for 10 hours to obtain Mimosa biochar (C-MP).

[0024] Mix and grind Mimosa biochar and analytically pure potassium hydroxide solid at a mass ratio of 1:0.5, then place in a box-type atmosphere furnace, and raise the temperature at a heating rate of 5°C / min under the protection of argon To 600°C, continue to activate f...

Embodiment 2

[0027] 15g of cut fresh mimosa were washed 3 times with absolute ethanol and deionized water, and then placed in a vacuum freeze dryer for 24 hours at a vacuum degree of 4.0Pa and at -103°C for lyophilization. Put the mimosa in a quartz boat and put it into a tube furnace. Under the protection of argon, first raise the temperature to 300°C at a rate of 5°C / min, carbonize at a low temperature for 3 hours, then raise the temperature to 600°C, and carbonize at a high temperature for 2 hours. After it was cooled to room temperature, the carbonized product was taken out, ground into powder, washed 6 times with absolute ethanol, and finally the carbonized product was dried in an oven at 80°C for 7 hours to obtain Mimosa biochar.

[0028] Mix and grind Mimosa biochar and analytically pure potassium hydroxide solid at a mass ratio of 1:4, then place them in a box-type atmosphere furnace, and raise the temperature at a heating rate of 5°C / min under the protection of argon To 900°C, con...

Embodiment 3

[0031] 15g of cut fresh mimosa were washed 3 times with absolute ethanol and deionized water, and then placed in a vacuum freeze dryer for 24 hours at a vacuum degree of 4.0Pa and at -103°C for lyophilization. Put mimosa in a quartz boat and put it into a tube furnace. Under the protection of argon, first raise the temperature to 400°C at a rate of 5°C / min, carbonize at low temperature for 2 hours, then raise the temperature to 750°C, and carbonize at high temperature for 2 hours. After it was cooled to room temperature, the carbonized product was taken out, ground into powder, washed 4 times with absolute ethanol, and dried in an oven at 70 °C for 10 h to obtain Mimosa biochar (C-MP).

[0032]Mix and grind Mimosa biochar and analytically pure potassium hydroxide solid at a mass ratio of 1:2, then place it in a box-type atmosphere furnace, and raise the temperature at a heating rate of 5°C / min under the protection of argon To 750°C, continue to activate for 2 hours, wait for i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com