A preparation method of composite shot blasting tube

A technology of shot blasting tube and shot blasting machine, which is applied in the field of preparation of compound shot blasting machine shot blasting tube, can solve the problems of no shot blasting machine and shot blasting tube, and achieve reduced scrap rate, low density, and thermal shock resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

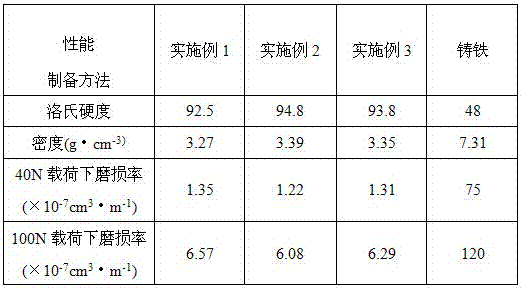

Examples

Embodiment 1

[0029] (1) Raw material preparation: Weigh 80 parts of silicon nitride powder, 10 parts of boron nitride nanotube powder, 5 parts of alumina powder and 5 parts of yttrium oxide powder according to the mass ratio to form the raw materials for preparation;

[0030] (2) Mixing of raw materials: Add the raw materials mentioned in step (1) into the ball mill tank, add alcohol according to the volume ratio of alcohol and raw materials at a ratio of 1:1 to make thinner, and add according to the mass ratio of steel balls and raw materials at 10:1 For steel balls, after sealing the ball mill jar, pass argon gas into the ball mill jar as a protective gas, and carry out ball milling and mixing of raw materials in a planetary ball mill, set the ball milling speed to 250 rpm, and the ball milling time to 10 hours. The raw material after ball milling was dried in a vacuum drying oven for 10 hours, and the set temperature was 75°C. Collect the dried mixed powder through a 300-mesh sieve;

...

Embodiment 2

[0037] (1) Raw material preparation: Weigh 82 parts of silicon nitride powder, 8 parts of boron nitride nanotube powder, 6 parts of alumina powder and 4 parts of yttrium oxide powder according to the mass ratio to form the raw materials for preparation;

[0038](2) Mixing of raw materials: Add the raw materials mentioned in step (1) into the ball mill tank, add alcohol according to the volume ratio of alcohol to raw materials at a ratio of 1:1 to make a thinner, and add it according to the mass ratio of steel balls to raw materials at 9:1 For steel balls, after the ball milling pot is sealed, argon gas is introduced into the ball milling pot as a protective gas, and the raw materials are ball milled and mixed in a planetary ball mill. The ball milling speed is set to 250 rpm, and the ball milling time is 8 hours. The ball-milled raw materials were dried in a vacuum drying oven for 12 hours, and the set temperature was 85°C. Collect the dried mixed powder through a 300-mesh sie...

Embodiment 3

[0045] (1) Raw material preparation: Weigh 85 parts of silicon nitride powder, 5 parts of boron nitride nanotube powder, 4 parts of alumina powder, and 3 parts of yttrium oxide powder according to the mass ratio to form the raw materials for preparation;

[0046] (2) Mixing of raw materials: Add the raw materials mentioned in step (1) into the ball mill tank, add alcohol according to the volume ratio of alcohol to raw materials at a ratio of 1:1 to make thinner, and add according to the mass ratio of steel balls to raw materials at 15:1 Steel balls, after sealing the ball milling pot, pass argon into the ball milling pot as a protective gas, and carry out ball milling and mixing of raw materials in a planetary ball mill, set the ball milling speed to 200 rpm, and the ball milling time to 12 hours. The raw material after ball milling was dried in a vacuum drying oven for 12 hours, and the set temperature was 75°C. Collect the dried mixed powder through a 300-mesh sieve;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com