A dual-purpose flexible processing device for grinding and polishing for substrate processing

A technology for flexible processing and grinding tools, applied in grinding tools, grinding drive devices, grinding/polishing equipment, etc., can solve problems such as easy cracking, pollution, easy warping and deformation, increase the processing contact area, avoid chemical Waste liquid, the effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

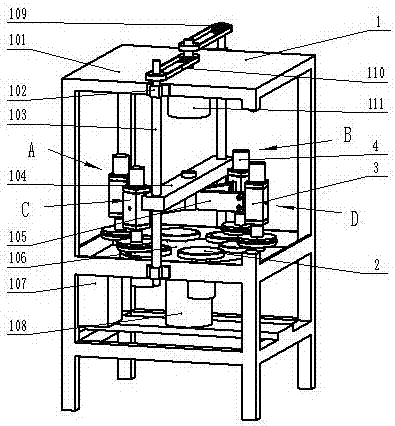

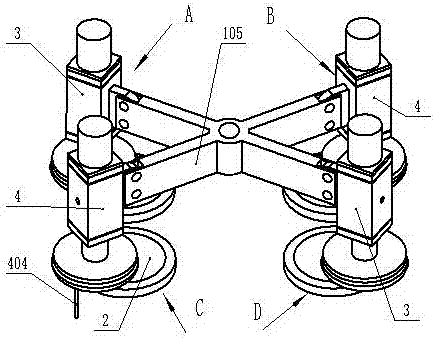

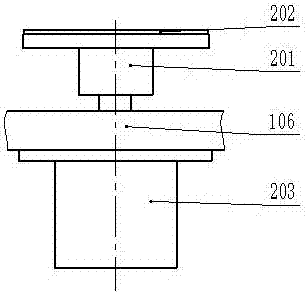

[0024] A dual-purpose flexible processing device for grinding and polishing for substrate processing, comprising a processing system host 1, a tooling suction cup tool 2, a pneumatic grinding tool 3, and a pneumatic polishing tool 4, characterized in that the processing system host 1, It includes a frame body 101, a bearing seat 102, a motor 108, a ball screw 103, a sliding table 104, a drive link 105, a turntable 106, a control box 107, a synchronous pulley 109, a synchronous belt 110 and a feed drive motor 111, wherein , the core component of the mainframe 1 of the processing system is the frame body 101, the top of the frame body 101 is installed with a feed drive motor 111, and the output shaft of the feed drive motor 111 is installed with a synchronous pulley 109 and Timing belt 110, four bearing seats 102 are installed on both sides of the frame body 101, ball sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com