Organic steam corrosion-resistant gas separation film and preparation method thereof

A gas separation membrane, organic vapor technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of damage, the base membrane is easily corroded, the membrane performance is degraded, etc. Separation selection performance, the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 3g of PEG400 and 1g of macromolecular PEG20000 mixed additives in N,N-dimethylformamide solvent at 40°C. After completely dissolving, add 15g of PVDF-HFP powder to the solution to prepare a casting solution with a total mass of 100g. Dissolve The temperature is maintained at 70°C. After obtaining a uniform and transparent casting solution, let it stand for 16 hours for defoaming, and evenly scrape it on the non-woven fabric with a scraper. The thickness of the scraper is 150 μm. , take it out immediately after staying for 2s, then immerse in deionized water for 30s, take out the membrane, and rinse the membrane surface with clean water for 30min repeatedly to obtain a PVDF-HFP porous base membrane. Dissolve the ternary copolymerization block silicone oil (if not specified, the ternary copolymerization block silicone oil is provided by Shandong Dayi Chemical Co., Ltd. in all examples) in the solvent toluene, mix well and add the crosslinking agent phenyl trimetho...

Embodiment 2~3

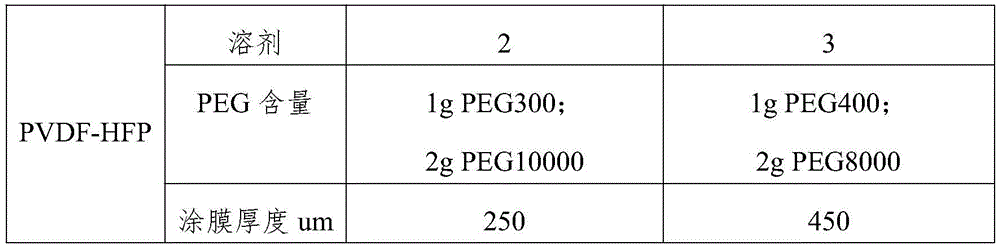

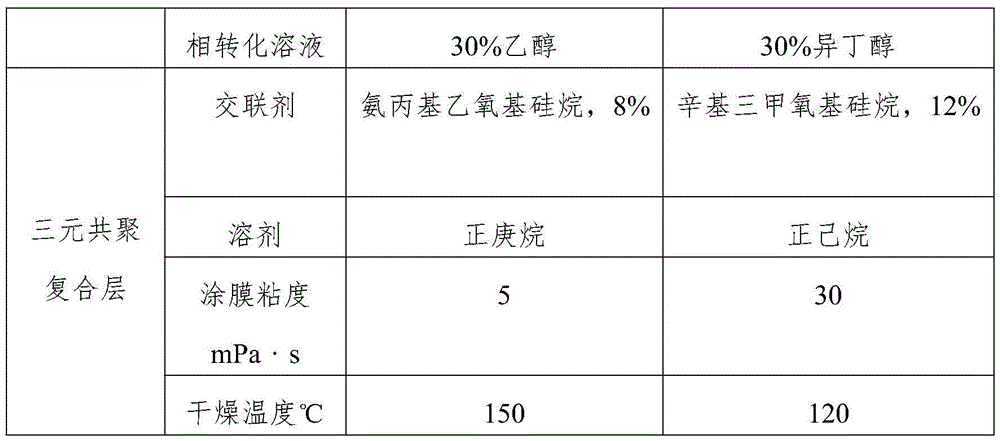

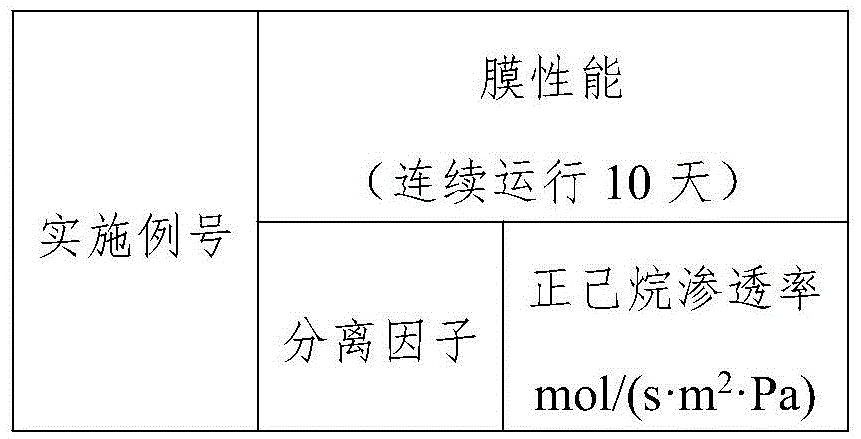

[0032] Examples 2-3 investigated the influence of coating film conditions on film performance and solvent resistance, and the rest of the conditions are the same as in Example 1. The conclusions are shown in Tables 2 to 4: the membrane with PVDF-HFP as the base membrane and ternary copolymerized silicone oil as the composite layer material maintains stable separation performance and has good solvent resistance during continuous operation.

[0033] Table 1 Embodiment 2~3 film-making conditions

[0034]

[0035]

Embodiment 4

[0037]Example 4 investigates the effect of using PVDF material as the base film on the performance and solvent resistance of the composite film during long-term operation, and the rest of the conditions are the same as in Example 1. The conclusions are shown in Tables 2 to 4: During the continuous operation of the membrane with PVDF as the base membrane and ternary copolymerized silicone oil as the composite layer material, the separation factor of the membrane and the permeation rate of n-hexane are both decreasing, which shows that PVDF is in the process of long-term operation. The substrate is easily eroded by n-hexane solvent, and the pores shrink and deform under the pressure of the membrane surface, resulting in a decrease in separation performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com