Suction type suture packaging clamp and winding process thereof

A technology for suture thread and packaging card, which is applied to surgical instruments, trocars, etc., can solve the problems of high knotting and easy knotting of threads, and achieves the effects of simple processing, convenient drawing and pulling, and saving assembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

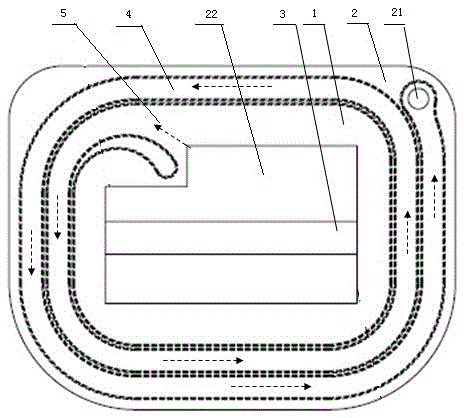

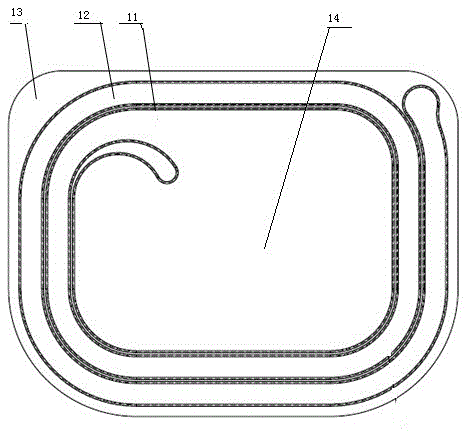

[0013] From figure 1 , figure 2 It can be seen from the figure that a suction-type suture packaging card includes a chassis 1, a paper cover 2, a needle-fixing spacer 3, and the like. The chassis 1 is processed from transparent polyester plastic.

[0014] The chassis 1 is provided with continuously surrounding raised strips 11 and grooves 12, the paper cover 2 is pasted and fixed on the chassis 1, and a continuous suture line slideway 4 is formed between the paper cover 2 and the chassis 1, The outer terminal of the corresponding suture slide 4 on the paper cover 2 is provided with an air suction port 21, and the inner terminal of the suture slide is the suction inlet 5 of the suture; an empty window 22 is arranged in the middle of the paper cover, and a needle pad Sheet 3 is glued to chassis 1 through the empty window.

[0015] Further, the continuously surrounding ridge strip 11 on the chassis 1 is on the same plane as the guard plate 13 around the chassis; the continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com