Method for synchronously preparing low-temperature squeezed peanut oil and semi-deoiled peanut snack food

A snack food and semi-degreased technology, applied in the field of food processing, can solve the problems of waste of by-product resources, deformation of peanut kernels, low granulation rate, etc., and achieve the effects of rich nutritional value, increased protein content, and low broken granulation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

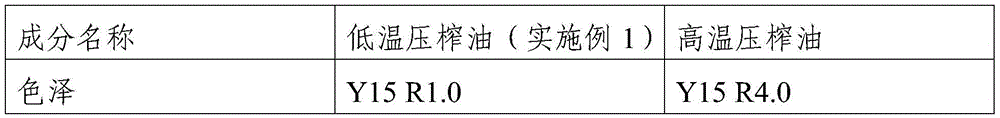

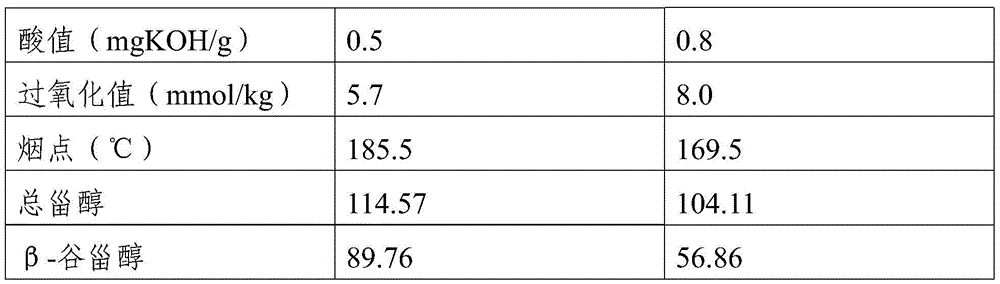

[0027] This embodiment provides a method for synchronously preparing low-temperature pressed peanut oil and semi-skimmed peanut snack food, comprising the following steps:

[0028] a. Select the red-coated peanuts of the small-grained Baisha variety as raw material, the moisture content is 4.88%, and the dry basis crude fat content is 44.21%.

[0029] b. Weigh 8 parts of the peanut raw material described in step a, each 800g, add pure water to adjust to 6%, put into the squeeze chamber after each part is wrapped with 4 layers of filter cloth, and each part is separated by a 2mm steel plate.

[0030] c. Step up the pressure from 2Mpa to 6Mpa every 5min, press for 15min, and control the pressing temperature at 50°C to obtain semi-defatted peanut kernels and low-temperature pressed peanut crude oil with a degreasing rate of 60.89%.

[0031] d. According to the ratio of 330g of water, 3.3g of aniseed, 3.3g of cinnamon and 10g of salt per 100g of semi-defatted peanut kernels, put t...

Embodiment 2

[0040] This embodiment provides a method for synchronously preparing low-temperature pressed peanut oil and semi-skimmed peanut snack food, comprising the following steps:

[0041] a. The red-coated peanuts of the large-grain Huayu 22 variety were selected as raw materials, the water content was 4.53%, and the dry basis crude fat content was 49.30%.

[0042] b. Weigh 8 parts of the peanut raw material described in step a, each 1000g, add pure water to adjust to 6.5%, put into the squeeze chamber after each part is wrapped with 4 layers of filter cloth, and each part is separated by a 2mm steel plate.

[0043] c. Gradiently increase the pressure from 4Mpa to 8Mpa every 10min, press for 35min, and control the pressing temperature at 27°C to obtain semi-defatted peanut kernels and low-temperature pressed peanut crude oil with a degreasing rate of 68.10%.

[0044] d. According to the ratio of 350g of water, 5g of aniseed, 5g of cinnamon and 12g of salt per 100g of semi-defatted pe...

Embodiment 3

[0048] This embodiment provides a method for synchronously preparing low-temperature pressed peanut oil and semi-skimmed peanut snack food, comprising the following steps:

[0049] a. Select the red-coated peanuts of the small-grained Baisha variety as raw material, the moisture content is 4.88%, and the dry basis crude fat content is 44.21%.

[0050] b. Weigh 8 parts of the peanut raw material described in step a, each 800g, add pure water and temper to 5%, put into the squeeze chamber after each part is wrapped with 4 layers of filter cloth, and each part is separated by a 2mm steel plate.

[0051] c. Step up the pressure from 2Mpa to 6Mpa every 5min, press for 20min, and control the pressing temperature at 50°C to obtain semi-defatted peanut kernels and low-temperature pressed peanut crude oil.

[0052] d. According to the ratio of 1400g water, 20g aniseed, 20g cinnamon, and 40g salt per 300g semi-defatted peanut kernels, put aniseed, cinnamon, and salt into water and boil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com