Warp correction method for sputtering target with backing plate

A sputtering target and backplate technology, which is applied in sputtering plating, metal material coating process, ion implantation plating, etc., can solve problems such as time-consuming and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In this embodiment 1, a diameter of 158.75 mm, a thickness of 3.17 mm and a composition of Fe-35Pt-15SiO 2 -10C sputtering target (SiO 2 , C relative to the overall target volume ratio are 38.47%, 4.99%, SiO 2 The volume ratio of the sum of C and C to the entire target material is 43.46 vol%). The sputtering target is SiO 2 and C dispersed in the matrix metal (FePt alloy) obtained by the complex.

[0072] An oxygen-free copper back plate with a diameter of 165.1 mm and a thickness of 3.18 mm was attached to this sputtering target using indium. When using indium for installation, heat the sputtering target, oxygen-free copper backplane, and indium to about 300°C, make the molten indium intervene between the sputtering target and oxygen-free copper backplane, cool to room temperature to make the indium Cured to bond the sputter target to the oxygen-free copper backplate.

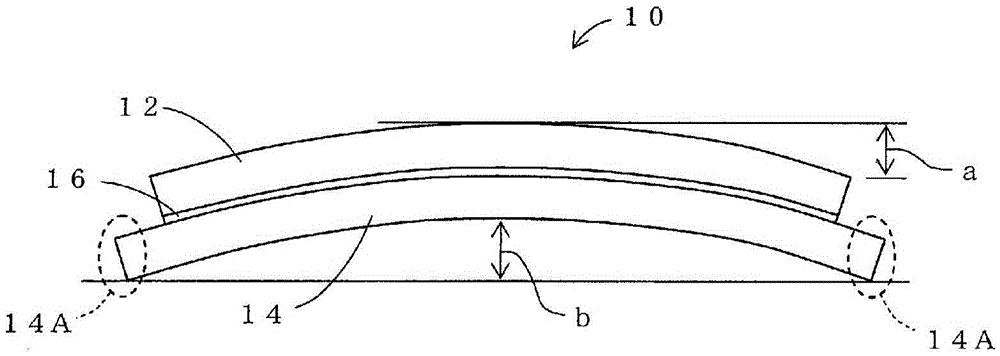

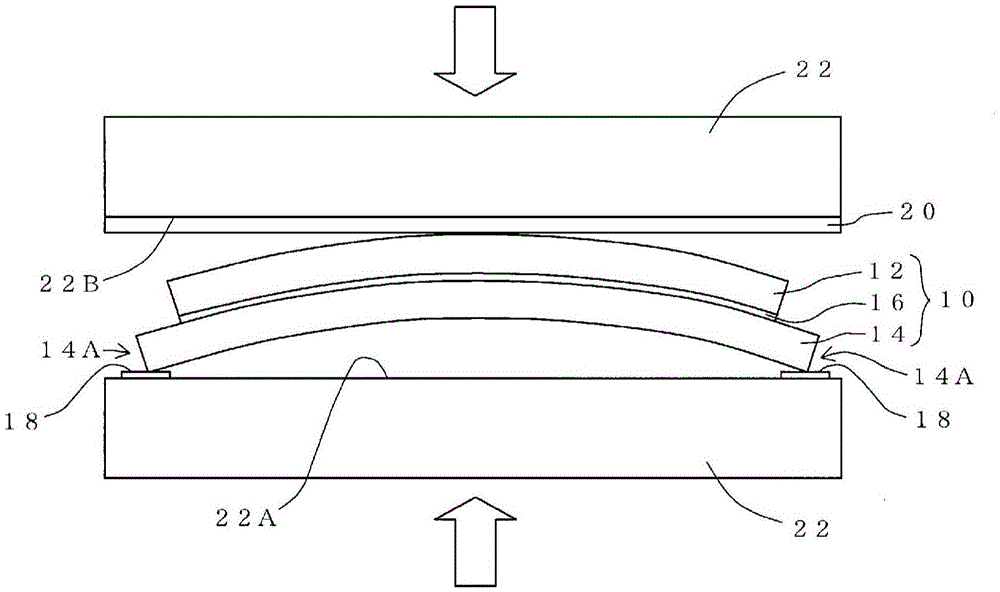

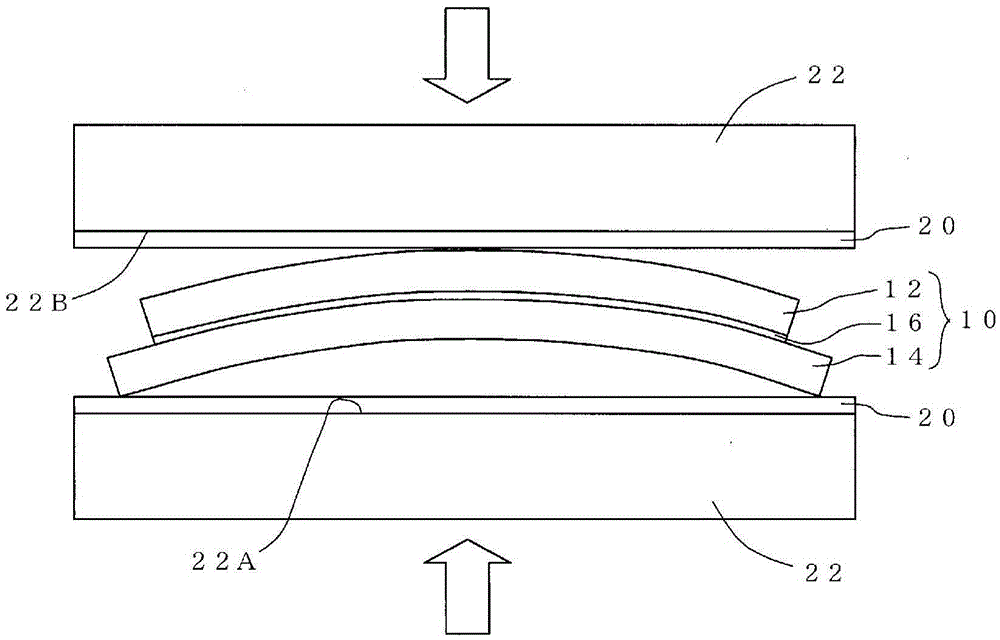

[0073] The amount of warping on the back plate side of the BP-attached target after cooling to ...

Embodiment 2

[0098] In Example 1, the press pressure to be applied was increased in four steps from 0.50MPa→2.48MPa→4.95MPa→14.86MPa, but in Example 2, pressurization at 14.86MPa was performed for only 10 minutes , pressurize in one stage.

[0099] Except for this, experiments were performed under the same conditions as in Example 1. In addition, in this Example 2, the same BP-attached target as in Example 1 was used.

[0100] In this Example 2, the amount of BP warping was measured after pressurization of 14.86 MPa for 10 minutes, and the amount of BP warping was 0.07 mm. The value of this BP warping amount is the same as the value of the BP warping amount after pressurization of 14.86 MPa was performed for 10 minutes in Example 1. Therefore, it can be considered that if the highest value of the pressing pressure finally applied and the time for applying the highest value of the pressing pressure are approximately the same, no matter whether the pressing force is gradually increased and...

Embodiment 3

[0102] In this embodiment 3, a diameter of 153 mm, a thickness of 3 mm and a composition of 85 (Co-40Cr)-15TiO 2 The sputtering target (TiO 2 The volume ratio to the entire target material is 33.02 vol%). The sputtering target is TiO 2 A composite obtained by dispersing in a base metal (CoCr alloy).

[0103] An oxygen-free copper back plate with a diameter of 161 mm and a thickness of 4 mm was attached to this sputtering target using indium. When using indium for installation, heat the sputtering target, oxygen-free copper backplane, and indium to about 300°C, so that the molten indium is interposed between the sputtering target and the oxygen-free copper backplane, and cool to room temperature to solidify the indium , and the sputtering target is bonded to the oxygen-free copper backplane.

[0104] The amount of warpage on the back plate side of the bonded target with BP after cooling to room temperature ( figure 1 The indicated BP warpage b) is 0.23 mm.

[0105] Next, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com