Preparation method of germanium nano-particle/multi-layer graphite compound-based high-performance anode material for lithium-ion battery

A lithium-ion battery and nanoparticle technology, applied in the field of electrochemistry, can solve the problems of using organic solvent system, application limitation of nanogermanium, toxicity of precursors, etc., and achieves improved electric capacity, good biocompatibility, good electrochemical performance, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

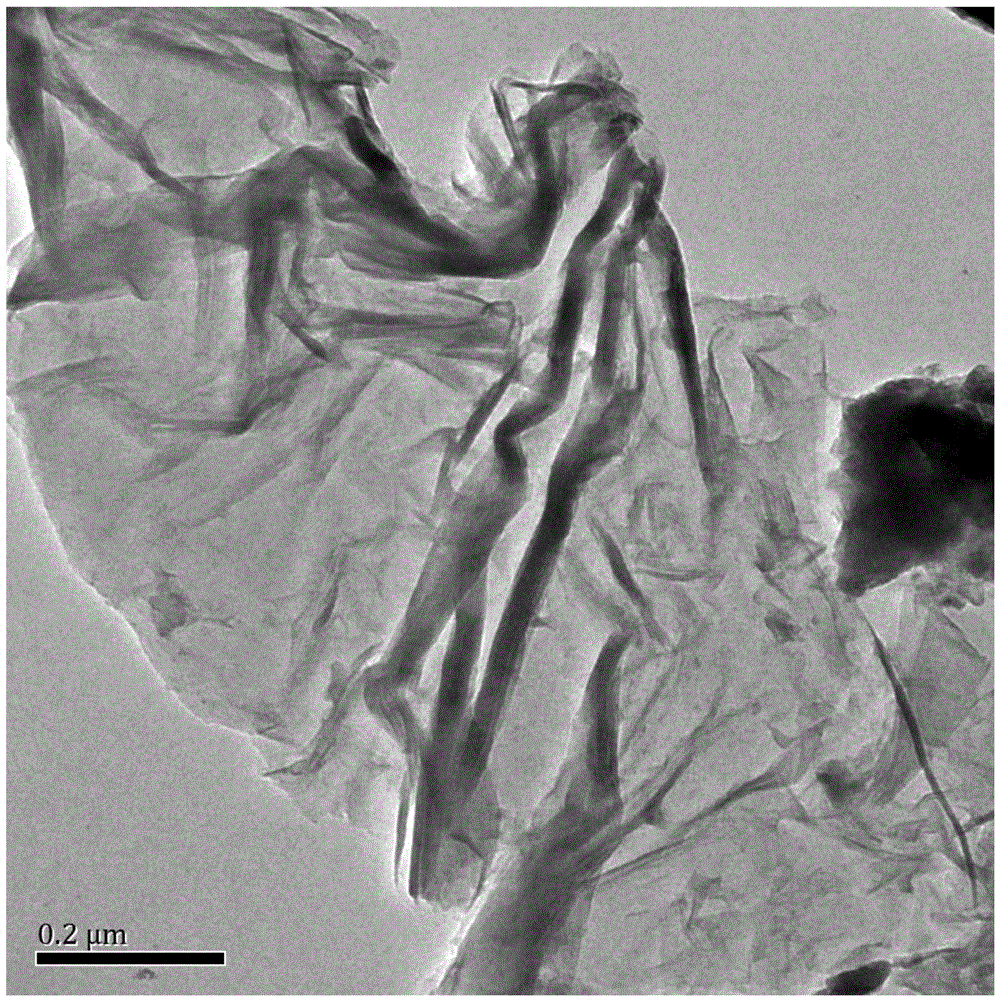

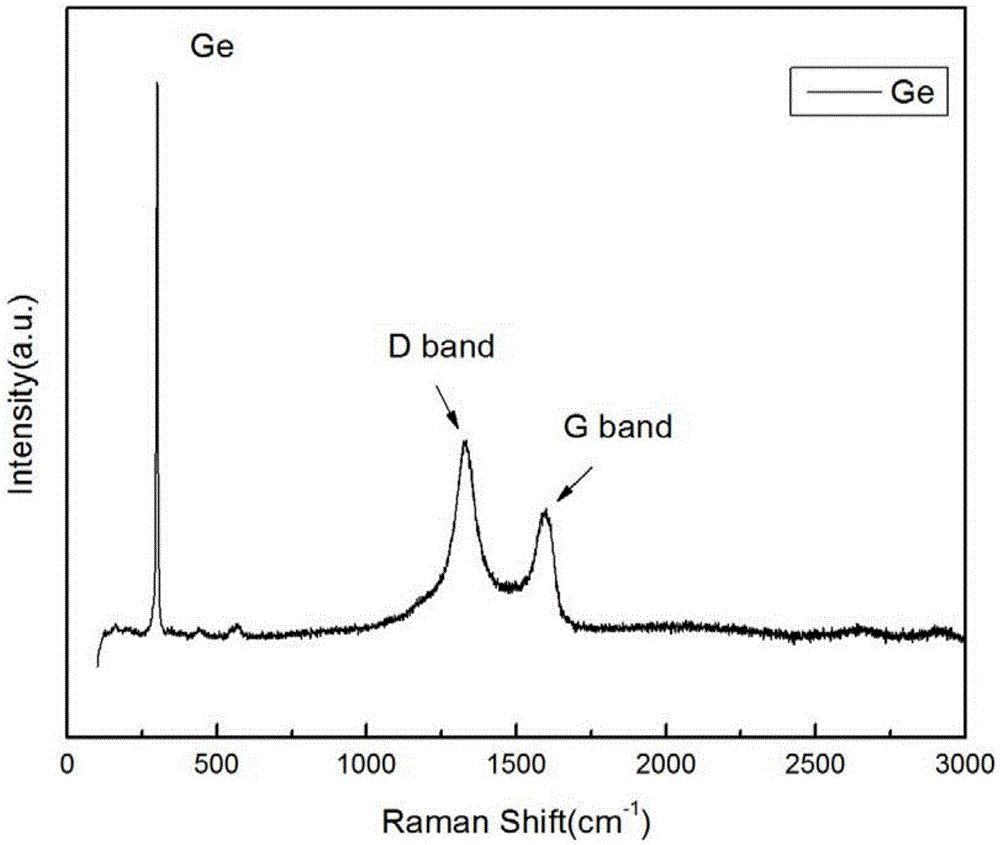

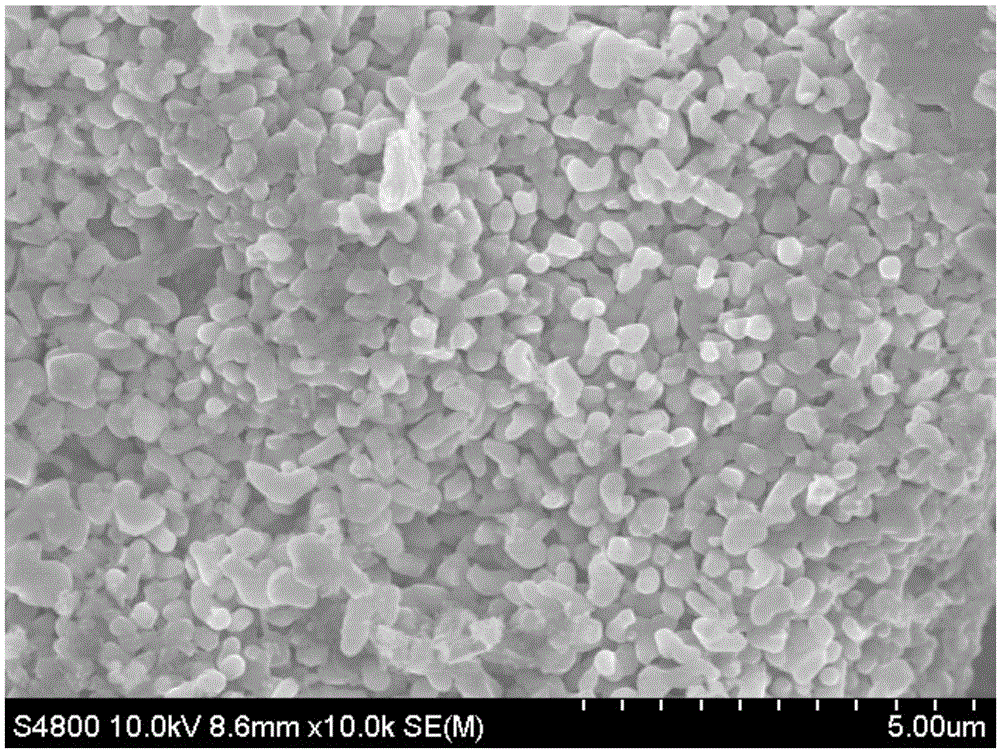

[0032] (1) Preparation of multilayer graphite oxide:

[0033] ①Expand expanded graphite powder at 900°C for 30s at high temperature to obtain flocculent expanded graphite;

[0034] 2. Get the flocculent expanded graphite 1g of the heat-treated step 1., mix with 6gKMnO 4 , 1gNaNO 3 Mix, and slowly add 60ml of concentrated sulfuric acid while stirring evenly, and continue stirring for 24h to obtain a reaction solution;

[0035] ③Add the reaction solution of step ② into 300ml deionized water, the mixed solution generates a lot of heat and bubbles, keep stirring until the temperature of the mixed solution is cooled, then add 15ml of 30wt% hydrogen peroxide to obtain a bright yellow graphite oxide solution;

[0036] 4. Filtrate the graphite oxide solution of step 3. while hot to obtain multilayer graphite oxide, wash the multilayer graphite oxide 1-2 times with 5% hydrochloric acid solution, then wash the multilayer graphite oxide 1-2 times with deionized water, and wash the mult...

Embodiment 2

[0049] (1) Preparation of multilayer graphite oxide:

[0050] ①Expand expanded graphite powder at 900°C for 30s at high temperature to obtain flocculent expanded graphite;

[0051] 2. Get the flocculent expanded graphite 1g of the heat-treated step 1., mix with 6gKMnO 4 , 1gNaNO 3 Mix, slowly add 60ml of concentrated sulfuric acid while stirring evenly, and continue stirring for 20h to obtain a reaction solution;

[0052] ③Add the reaction solution of step ② into 300ml deionized water, the mixed solution generates a lot of heat and bubbles, keep stirring until the temperature of the mixed solution is cooled, then add 15ml of 30wt% hydrogen peroxide to obtain a bright yellow graphite oxide solution;

[0053] 4. Filtrate the graphite oxide solution of step 3. while hot to obtain multilayer graphite oxide, wash the multilayer graphite oxide 1-2 times with 5% hydrochloric acid solution, then wash the multilayer graphite oxide 1-2 times with deionized water, and wash the multilay...

Embodiment 3

[0063] (1) Preparation of multilayer graphite oxide:

[0064] ①Expand expanded graphite powder at 900°C for 30s at high temperature to obtain flocculent expanded graphite;

[0065] 2. Get the flocculent expanded graphite 1g of the heat-treated step 1., mix with 6gKMnO 4 , 1gNaNO 3 Mix, and slowly add 60ml of concentrated sulfuric acid while stirring evenly, and continue stirring for 30h to obtain a reaction solution;

[0066] ③Add the reaction solution of step ② into 300ml deionized water, the mixed solution generates a lot of heat and bubbles, keep stirring until the temperature of the mixed solution is cooled, then add 15ml of 30wt% hydrogen peroxide to obtain a bright yellow graphite oxide solution;

[0067] 4. Filtrate the graphite oxide solution of step 3. while hot to obtain multilayer graphite oxide, wash the multilayer graphite oxide 1-2 times with 5% hydrochloric acid solution, then wash the multilayer graphite oxide 1-2 times with deionized water, and wash the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com