Mass concrete microscopic fracture testing system

A large-volume concrete, cracking test technology, applied in the direction of material analysis, measuring devices, instruments, etc., using acoustic wave emission technology, can solve the problem of inability to simulate the degree of constraint and temperature development process, unsuitable for large-volume concrete crack resistance, test methods Unable to respond to problems such as microscopic cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

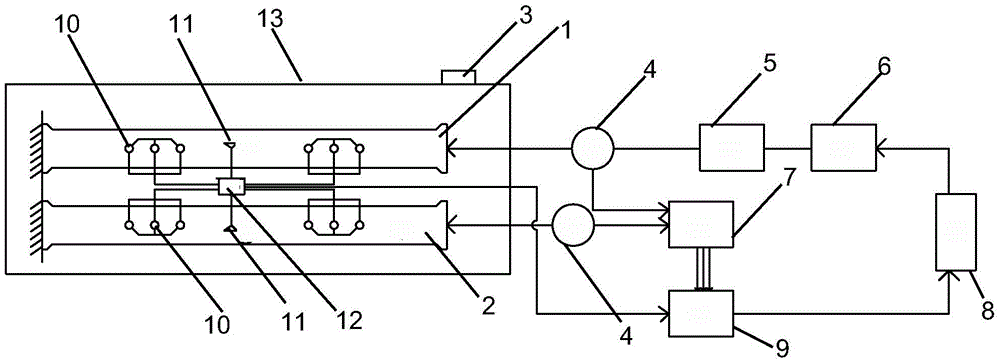

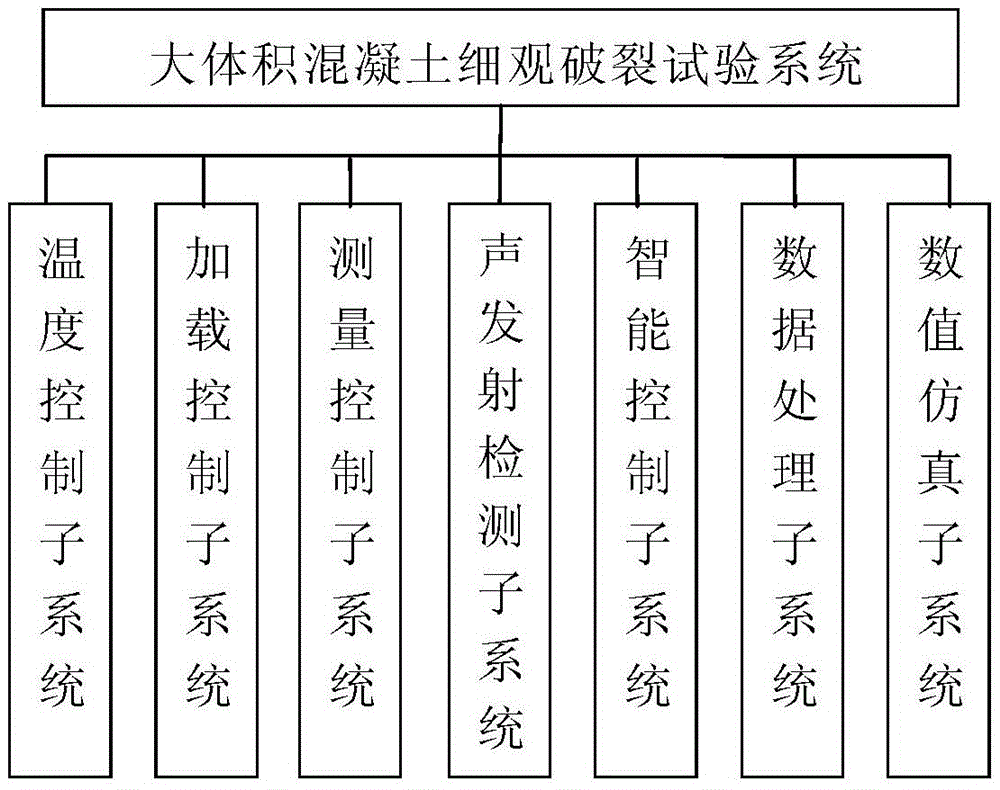

[0021] figure 1 It is a system composition block diagram of the present invention. As shown in the figure, the large-volume concrete mesoscopic cracking test system disclosed by the present invention includes a temperature stress testing machine and an acoustic emission detection device,

[0022] The temperature stress testing machine comprises a casing 13 for accommodating concrete specimens (constrained specimen 1 and free specimen 2), a heating and cooling system 3 on the chassis, a displacement sensor 4, a load cell 5, a stepper motor 6, The controller 8 used to control the action of the stepper motor, the signal amplifier 7 and the server 9 used to amplify the collected signal; the constrained specimen (shrinking under restrained conditions) and the free specimen ( Free contraction) is placed in the chassis, one end of the constrained s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com