Evaporative condensation air-conditioning heat pump system

A technology of evaporative condensation and evaporative condenser, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of low efficiency of air side heat exchanger, low energy efficiency of refrigeration system, and small specific heat capacity of air, etc. Achieve the effects of reducing the risk of fouling, efficient and reliable operation, and a small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

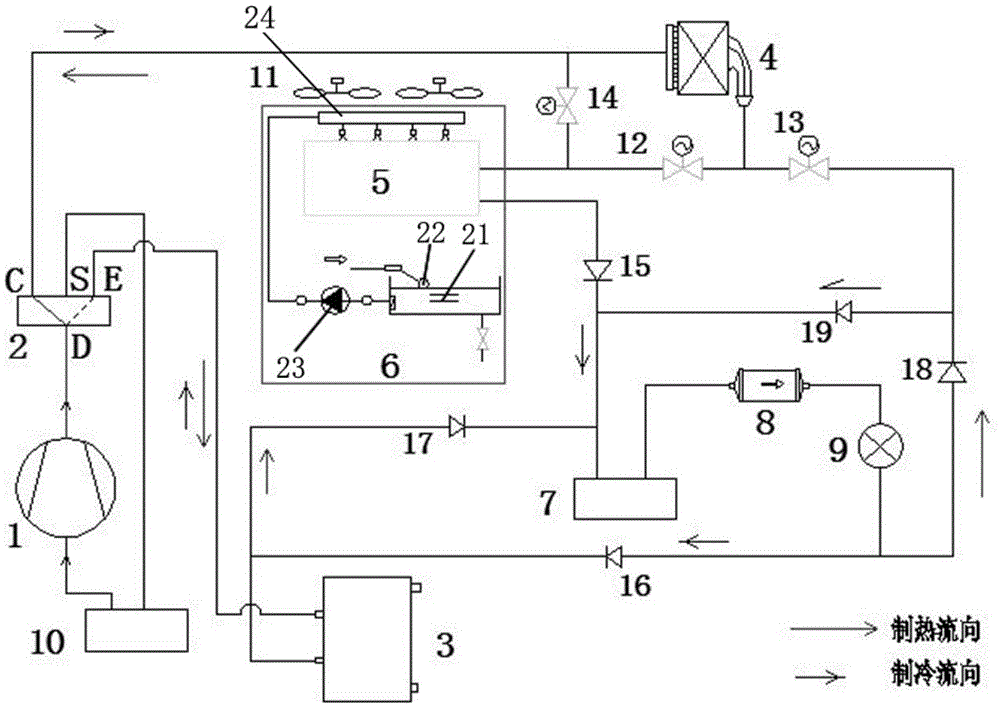

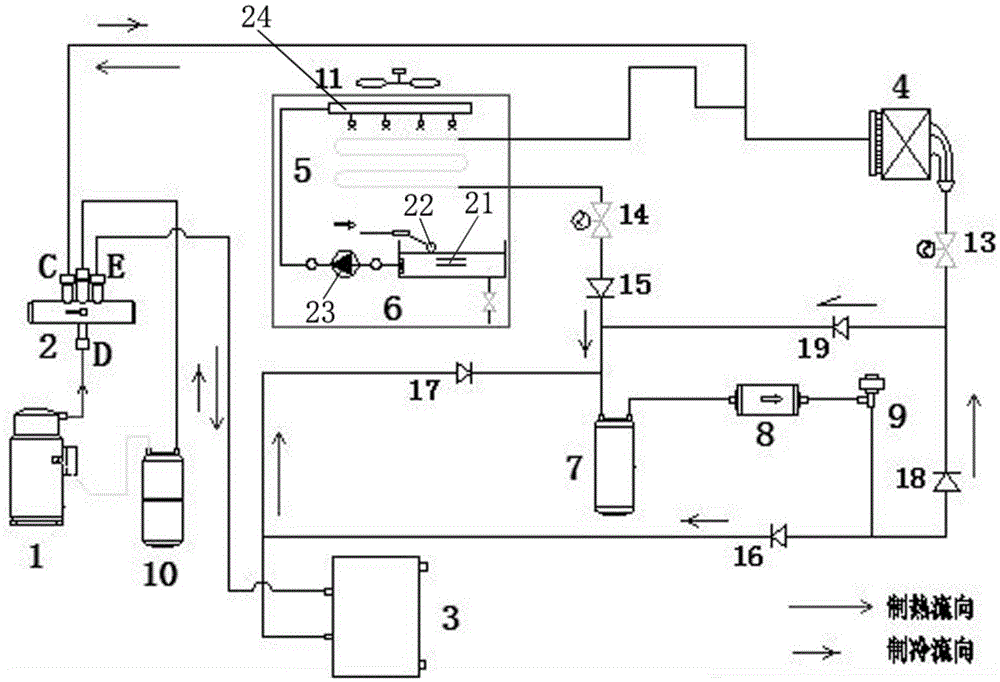

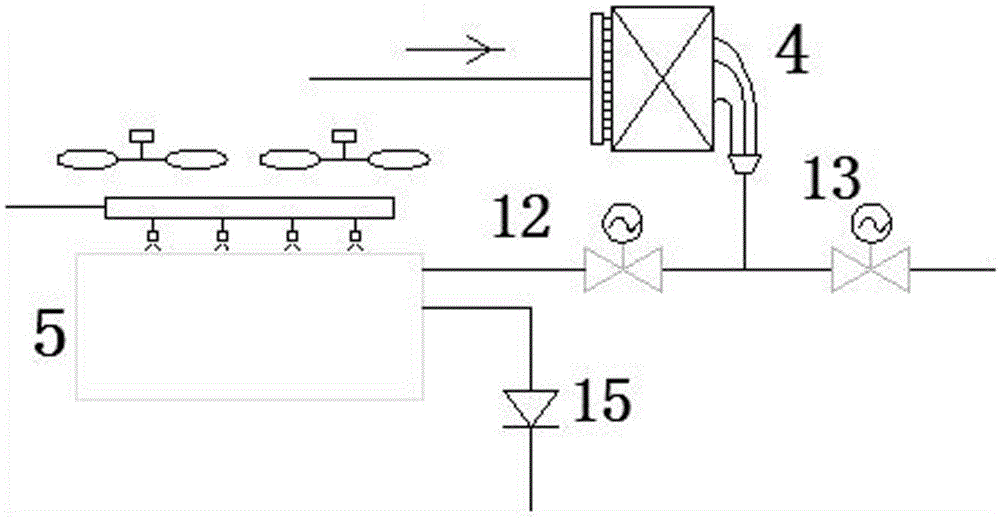

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0024] This evaporative condensing air-conditioning heat pump system is characterized in that it consists of a compressor 1, a four-way valve 2, a use-side heat exchanger 3, a finned tube heat exchanger 4, an evaporative condenser 5, a spray water device 6, Liquid reservoir 7, dry filter 8, throttling device 9, vapor-liquid separator 10, fan 11, solenoid valve D12, solenoid valve A13, solenoid valve B14, one-way valve, pipeline and control circuit, finned tube The heat exchanger 4 and the evaporative condenser 5 are arranged in series and parallel, and are connected to the condenser pipe end of the four-way valve 2. The outlet end of the other is connected to the inlet pipeline of the liquid receiver 7; the cooling and heating functions rely on the four-way valve 2 to switch the suction and exhaust flow direction of the compressor 1, and the flow direction is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com