A kind of sponge unit automatically sticking the sheet metal parts of two air conditioners and using method thereof

A technology for automatic pasting and sheet metal parts. It is applied in the direction of connecting components, conveyor objects, and material gluing. It can solve the problems of low equipment utilization, affecting the pasting effect, and greatly affecting the production progress, so as to ensure the pasting effect and pasting high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

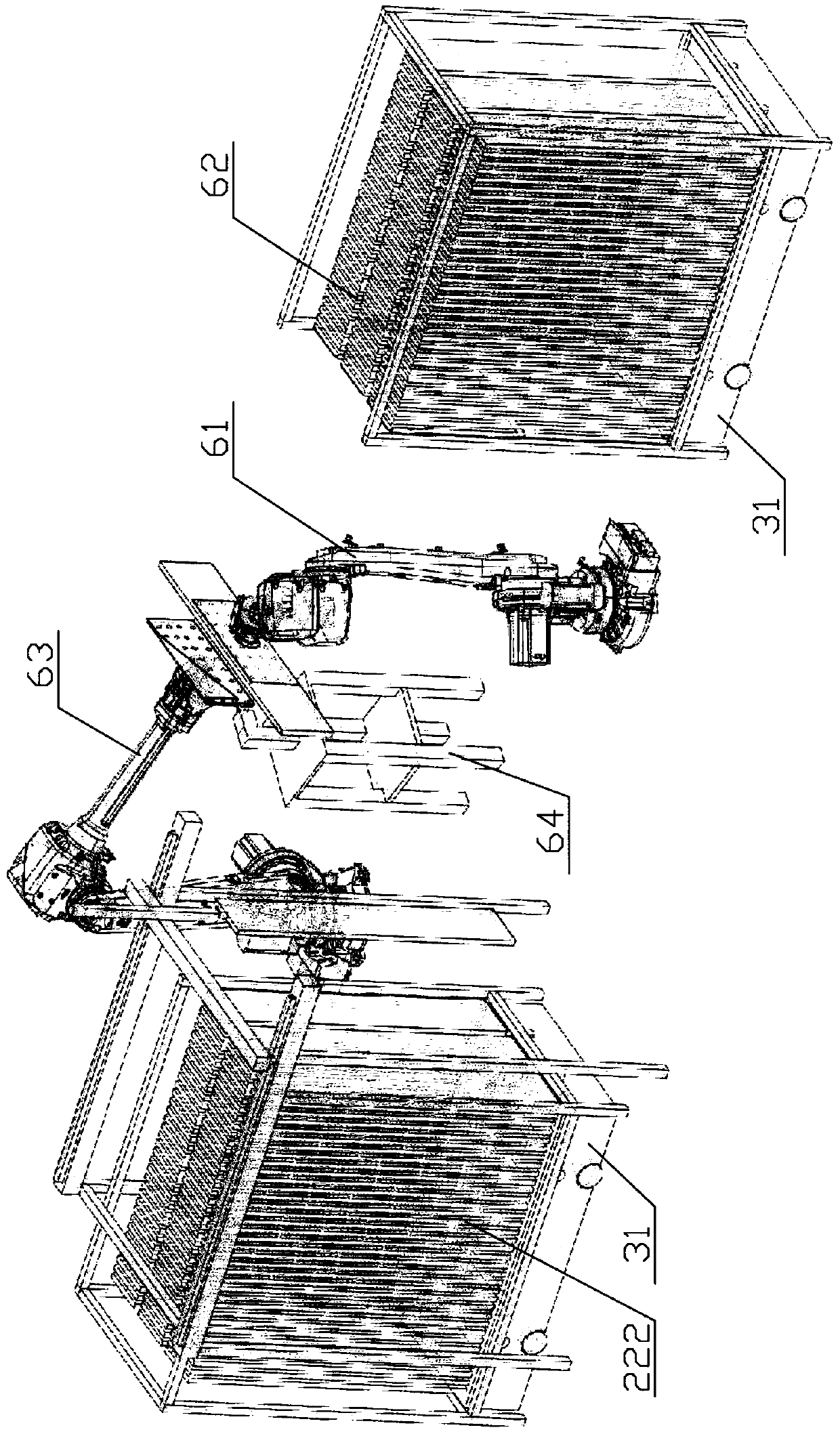

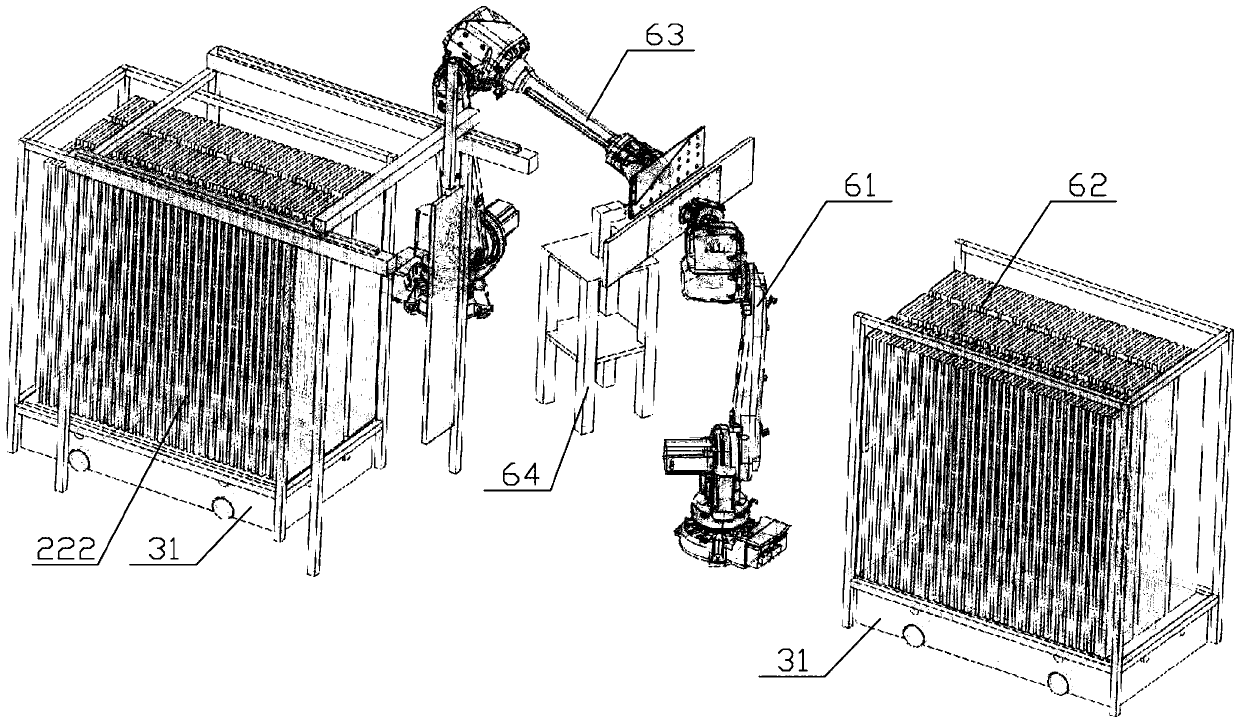

[0029] Such as figure 1 As shown, the sponge unit 6 for automatically pasting the sheet metal parts of the two air conditioners includes a sheet metal grabbing device 61, a sponge part bracket 62, a sponge part grabbing device 63, a positioning peeling film device 64 and electric control components.

[0030] The sheet metal grabbing device 61 includes a mechanical arm and a grabbing and stacking manipulator. The robotic arm includes at least one X-coordinate drive mechanism or a Y-coordinate drive mechanism and a Z-coordinate drive mechanism. The distal section of the arm, including the gripping mechanism and pattern recognition sensors;

[0031] The sponge component grabbing device 63 includes a mechanical arm and a grabbing and stacking manipulator. The robotic arm includes at least one X-coordinate drive mechanism or a Y-coordinate drive mechanism and a Z-coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com