Packaging bag label automatic pasting machine

A technology of automatic sticking and packaging bags, applied in the field of labeling equipment and automatic labeling equipment, can solve the problems of high labor intensity of operators, restricting the production efficiency of enterprises, and increasing production costs of enterprises, so as to reduce labor costs and achieve good sticking effect. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

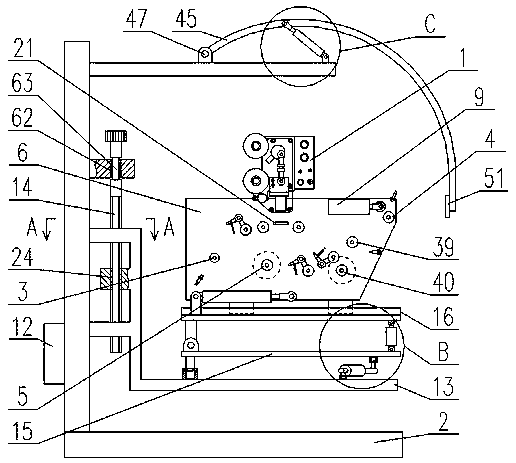

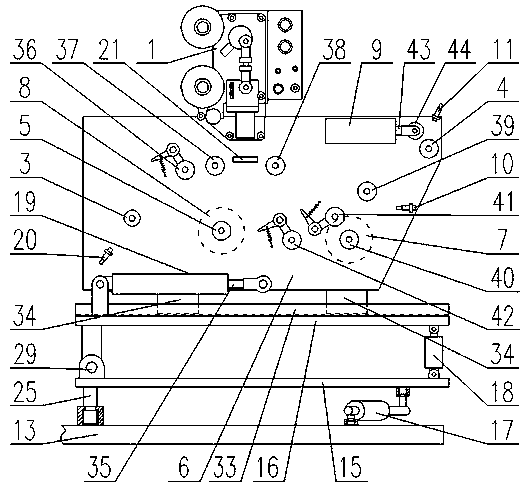

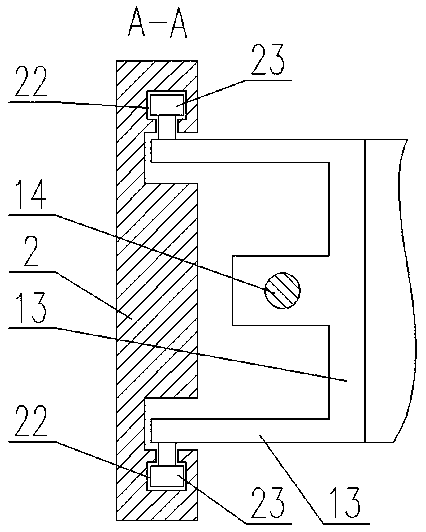

[0023] Depend on figure 1 As shown, the packaging bag label automatic sticking machine includes a ribbon coding machine 1, a frame 2, a label roller 3, a winding roller, a peeling roller 4, a winding roller 5, a bracket 6, and a driving motor 7 , winding motor 8, pasting cylinder 9, bag pressing mechanism, bag position sensor 10, label paper sensor 11, controller 12, base 13, adjusting screw 14, first bottom plate 15, second bottom plate 16, first cylinder 17 , vertical cylinder 18, horizontal cylinder 19 and paper roll sensor 20, by figure 2 As shown, the support 6 is installed on the frame 2, and is installed as follows: by image 3 As shown, a vertical guide groove 22 is provided on the frame 2 , and a pulley 23 is provided on the base 13 , and the base 13 is movably engaged in the vertical guide groove 22 of the frame 2 through the pulley 23 . A threaded hole 24 is provided on the base 13, a hole 62 is provided on the frame 2, an annular limiting groove 63 is provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com