Automatic pasting device for square battery insulation meson

A technology of automatic pasting and square batteries, which is applied in the direction of secondary batteries, secondary battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of many human-influenced factors, poor product consistency, time-consuming and labor-consuming, and achieve pasting quality High, consistent, fast-paced results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

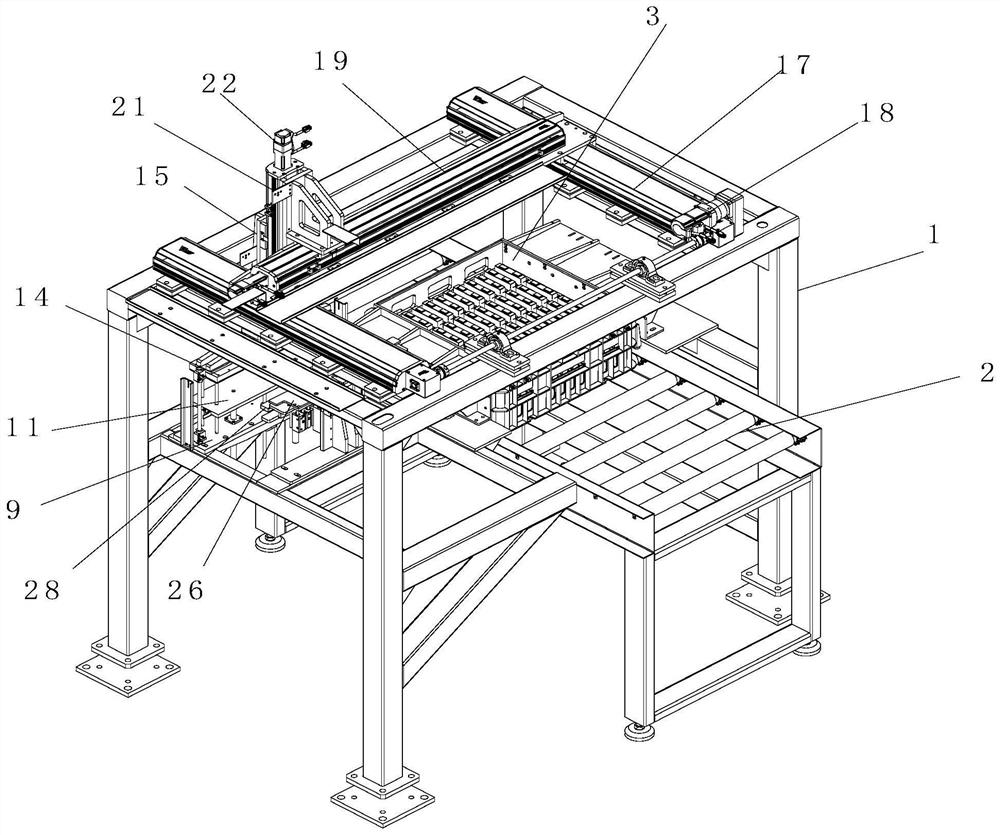

[0025] refer to Figure 1-Figure 8 , the present invention proposes a square battery insulator automatic pasting device, including a frame 1, an insulator mechanism, a sucker mechanism and a three-axis module mechanism; wherein:

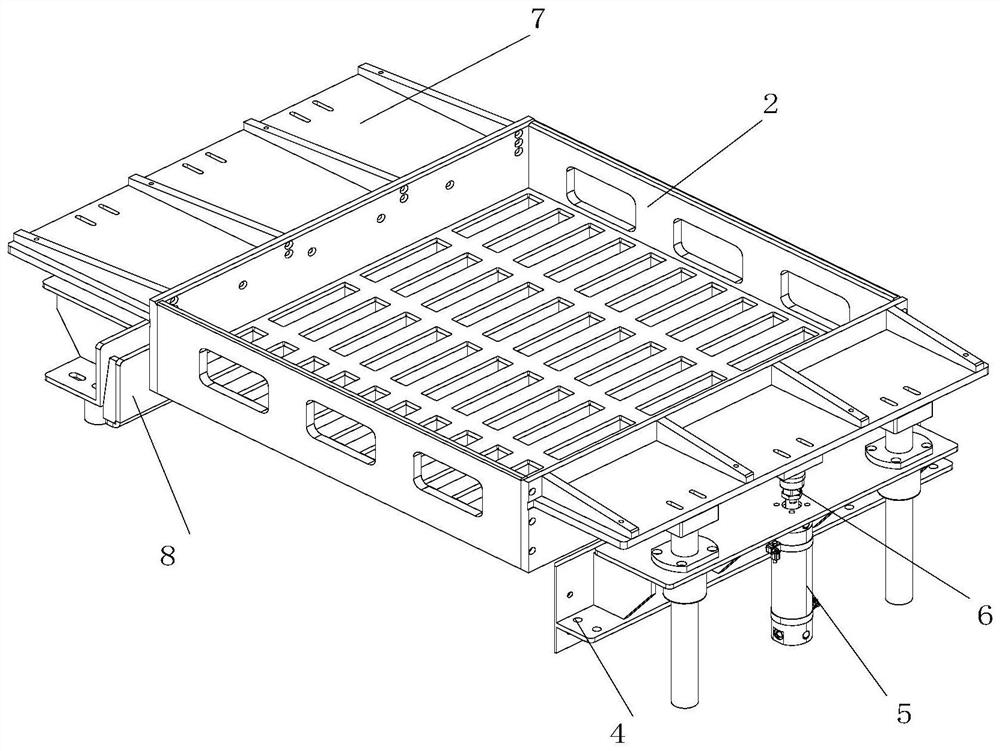

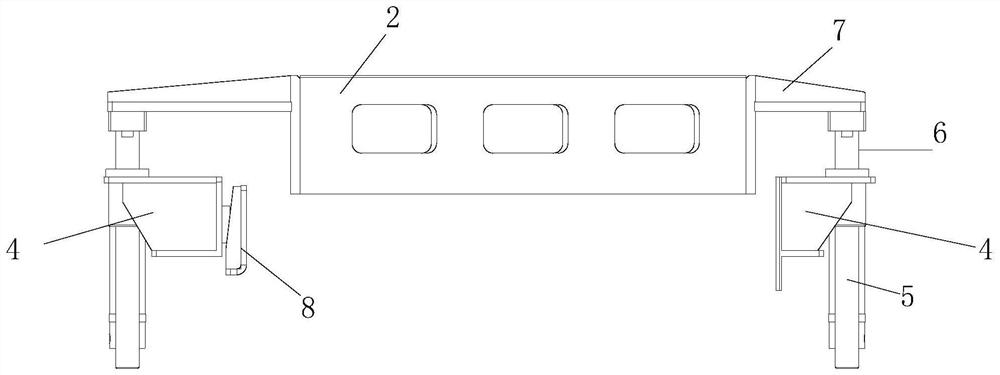

[0026] A transport roller set 2 is installed on the frame 1, and the transport roller set 2 is used to transport the tray 3 loaded with batteries, and the transport roller set 2 is provided with a tray positioning mechanism.

[0027] The insulating meson supply mechanism is installed on the frame 1 and is used for supplying insulating mesons.

[0028] Both the suction cup mechanism and the three-axis module mechanism are installed on the frame 1, and the three-axis module mechanism is used to control the movement of the suction cup mechanism to absorb the insulating meson on the insulating meson mechanism and control the movement of the suction cup mechanism to paste the insulating meson to the battery in the tray 3 superior.

[0029] The release p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com