Electromagnetic reduction roasting method and device for manganese oxide ores

A roasting device and manganese oxide technology, applied in the field of manganese oxide ore electromagnetic reduction roasting and equipment, can solve the problems of poor operating environment for workers, leakage of sulfur dioxide gas, etc., and achieve the effects of facilitating process control, prolonging service life, and preventing material sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

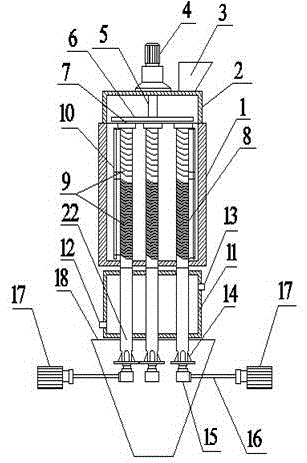

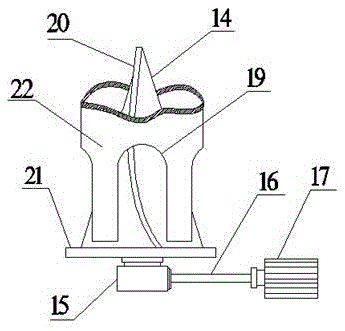

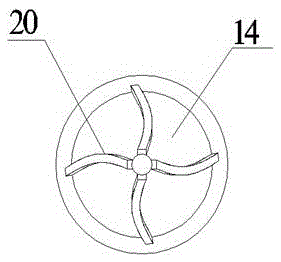

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0035] Embodiment of the present invention: a method for electromagnetic reduction roasting of manganese oxide ore, the method is by winding the LC oscillation line 9 outside the roasting tube 8, the LC oscillation line 9 generates an alternating magnetic field, and the alternating magnetic field makes the LC oscillation line 9 The inner roasting tube 8 generates heat by itself after induction, providing a reaction environment for the manganese oxide ore in the roasting tube 8 .

[0036] By selecting the LC oscillating line 9 as a hollow copper tube, and passing cooling water in the tube, the temperature outside the roasting tube 8 is lowered.

[0037] By arranging an insulating glass wool layer between the LC oscillating line 9 and the roasting tube 8, the temperature outside the roasting tube 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com