Nanowhisker excited insulating layer plastering gypsum and preparation method thereof

A technology of nano-whiskers and plastering gypsum, which is applied in the field of building materials, can solve the problems of weak interface between polystyrene particles and inorganic gelling components, weak adhesion of the base wall, falling off of the insulation layer and damaging pedestrians, etc. , to achieve the effect of improving interface contact, low dry density, good construction and workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

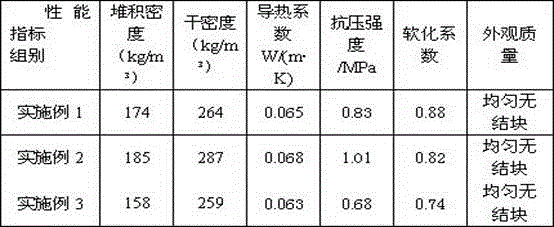

Embodiment 1

[0028] A preparation method of nano-whisker-excited plaster for insulation layer, each raw material is counted in parts by weight, and the specific preparation method is as follows:

[0029] 33 parts of α-type high-strength building gypsum, 0.02 parts of nano-tin oxide, 20 parts of plastic powder, 0.12 parts of hydroxypropyl methylcellulose, 0.15 parts of redispersible latex powder, 0.02 parts of starch ether, 0.06 parts of silica fume, water-reducing Add 0.05 parts of water-repellent agent, 0.15 parts of hydrophobic agent, 0.11 parts of polypropylene fiber, 0.08 parts of wood fiber, 0.04 part of polyvinyl alcohol, 0.15 parts of high-protein gypsum retarder and 0.05 part of air-entraining agent into the coulter with fast flying knife Mix evenly in a single-shaft mixer, send the mixed materials into the drum mixer, and add 40 parts of vitrified microbeads and 6 parts of vitrified microbeads fine powder into the tumbler mixer, and mix evenly to obtain nano Whisker inspired insul...

Embodiment 2

[0031] A preparation method of nano-whisker-excited plaster for insulation layer, each raw material is counted in parts by weight, and the specific preparation method is as follows:

[0032] 39 parts of α-type high-strength building gypsum, 0.006 parts of nano-zinc stannate, 0.014 parts of nano-zinc oxide, 10 parts of plastic powder, 0.12 parts of hydroxypropyl methylcellulose, 0.2 parts of redispersible latex powder, and 0.02 parts of starch ether, 0.08 parts of silica fume, 0.05 parts of superplasticizer, 0.1 parts of water-repellent agent, 0.1 part of polypropylene fiber, 0.07 part of wood fiber, 0.02 part of polyvinyl alcohol, 0.2 part of high-protein gypsum retarder and 0.02 part of air-entraining agent Mix evenly in a coulter-type single-shaft mixer with a fast flying knife, send the mixed raw materials into the drum mixer, and add 40 parts of vitrified microbeads and 10 parts of vitrified microbeads fine powder into the tumbler mixer parts, mix evenly to paint gypsum fo...

Embodiment 3

[0034] A preparation method of nano-whisker-excited plaster for insulation layer, each raw material is counted in parts by weight, and the specific preparation method is as follows:

[0035] 40 parts of α-type high-strength building gypsum, 0.02 parts of nano-hydroxy stannate zinc, 10 parts of plastic powder, 3 parts of first-grade fly ash, 4 parts of calcium-based bentonite, 38 parts of vitrified microbeads, and 4 parts of vitrified microbead fine powder 0.1 part of methyl cellulose, 0.2 part of redispersible latex powder, 0.02 part of starch ether, 0.06 part of silica fume, 0.1 part of water reducing agent, 0.05 part of hydrophobic agent, 0.1 part of polypropylene fiber, 0.06 part of wood fiber, poly Add 0.05 parts of vinyl alcohol, 0.2 parts of high-protein gypsum retarder and 0.04 parts of air-entraining agent into the coulter type single-shaft mixer with fast flying knife and mix evenly, and send the mixed materials into the drum mixer At the same time, add 38 parts of vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com