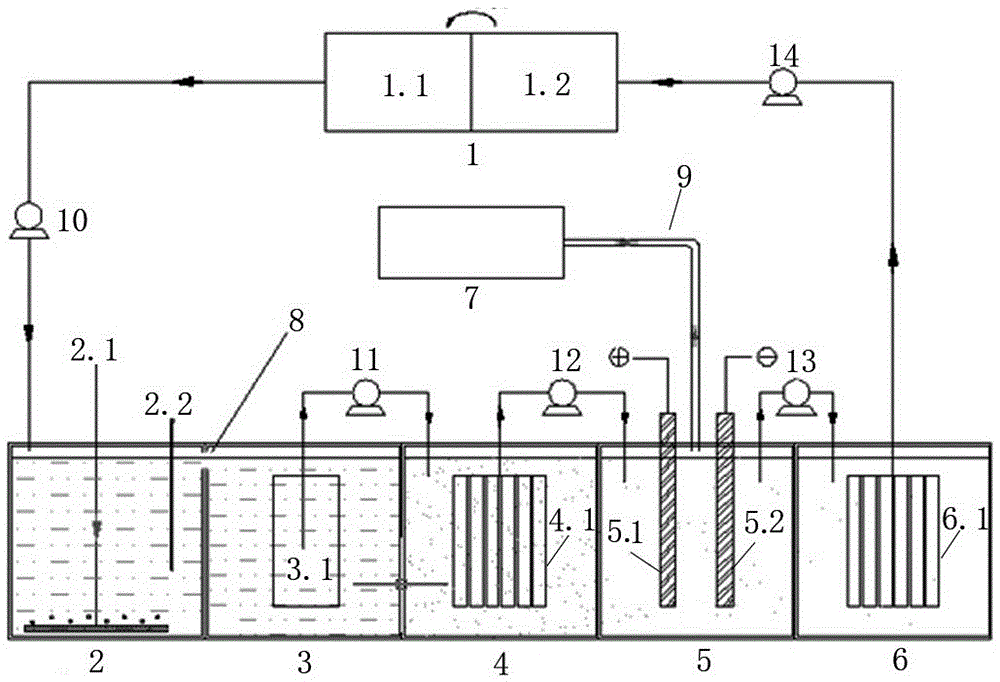

PCB ammonia-nitrogen wastewater zero discharge treatment method and device thereof

A technology for ammonia nitrogen wastewater and treatment methods, applied in water/sewage treatment, natural water treatment, neutralized water/sewage treatment, etc., can solve problems such as not suitable for zero discharge indicators, low treatment efficiency, large land occupation, etc., and achieve environmental protection significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

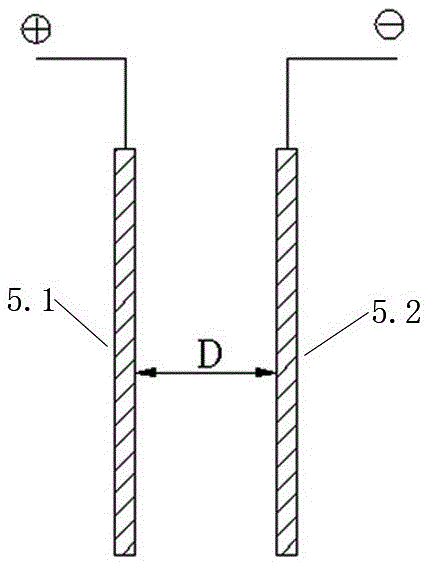

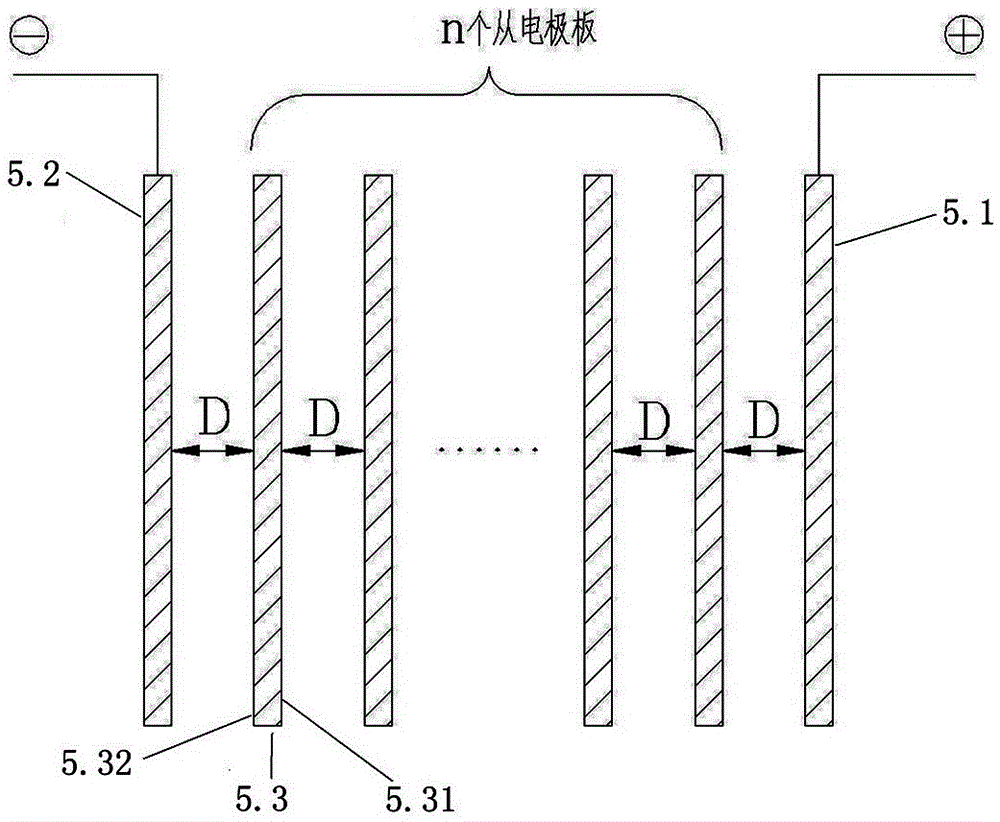

[0068] Adjust the pH of the etching wastewater (i.e. primary washing water) to 10-11, and filter out Cu(OH) by filter bag and ultrafiltration system 2 Finally, the water is introduced into the electrolysis system, and the same sewage is electrolyzed with different current densities and different distances between electrode plates, and the electrolyzed water is directly reused to the secondary washing in the etching section after an ultrafiltration, and the secondary washing overflows to First-level water washing, using alkaline etching solution to absorb the gas generated by electrolysis. According to this, the system is continuously circulated for one week, and the concentration of each pollutant in the secondary washing water on the first day and the seventh day is detected and tracked during the implementation process. The specific implementation conditions and implementation effects are detailed in Table 3.

[0069] Implementation conditions and effects of table 3 embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com