Method for preparing graphene nanoplatelets with disk type jet mill

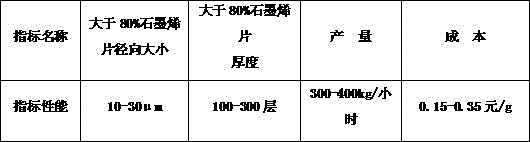

A technology of graphene microchips and jet pulverizers, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of small output, high production cost of graphene, complicated preparation process, etc., and achieve low cost and high production efficiency. The method is easy and the number of layers is uniformly dispersed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing graphene microflakes using a disc jet mill:

[0029] (1) Mixing 90 parts by weight of highly oriented graphite powder and 0.5 parts by weight of benzyl benzoate in a high-speed mixing reactor, stirring and dispersing for 45 min at a rotating speed of 400 rpm, to obtain mixed powder;

[0030] (2) ferric chloride, acetic anhydride and acetic acid are prepared into intercalating agent with mass ratio of 2:1:1, and then the mixed powder obtained in step (1) is soaked in a closed high-speed agitator equipped with intercalating agent 15h, during the soaking process, the air pressure of the closed high-speed agitator was pumped to 50KPa, while stirring at a speed of 300rpm; then the pre-intercalated powder was obtained by filtering and drying through a centrifuge;

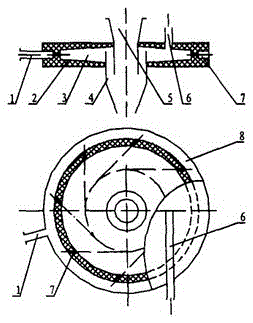

[0031] (3) The pre-intercalated powder obtained in step (2) is sent into a disc jet mill, which is provided with eight working nozzles, each of which is sprayed into the working cavity at a p...

Embodiment 2

[0033] A method for preparing graphene microflakes using a disc jet mill:

[0034] (1) Mixing 100 parts by weight of thermally cracked graphite powder and 1.5 parts by weight of benzyl benzoate in a high-speed mixing reactor, stirring and dispersing for 60 min at a rotating speed of 500 rpm, to obtain mixed powder;

[0035] (2) ferric chloride, acetic anhydride and acetic acid are prepared into intercalating agent with mass ratio of 3:1.5:1, and then the mixed powder obtained in step (1) is soaked in a closed high-speed agitator equipped with intercalating agent 20h, during the soaking process, the air pressure of the airtight high-speed agitator was pumped to 60KPa, while stirring at a speed of 500rpm; then the pre-intercalated powder was obtained by filtering and drying through a centrifuge;

[0036] (3) The pre-intercalated powder obtained in step (2) is sent to the disc jet mill, which is provided with eight working nozzles, each of which is sprayed into the working chambe...

Embodiment 3

[0038] A method for preparing graphene microflakes using a disc jet mill:

[0039] (1) 95 parts by weight of expanded graphite powder and 0.8 parts by weight of benzyl benzoate are mixed in a high-speed mixing reaction machine, stirred and dispersed for 50 min at a rotating speed of 450 rpm to obtain mixed powder;

[0040] (2) ferric chloride, acetic anhydride and acetic acid are prepared into intercalation agent with mass ratio of 2.4:1.2:1, then the mixed powder obtained in step (1) is soaked in a closed high-speed agitator equipped with intercalation agent 18h, during the soaking process, the air pressure of the closed high-speed agitator was pumped to 55KPa, while stirring at a speed of 360rpm; then the pre-intercalated powder was obtained by filtering and drying through a centrifuge;

[0041] (3) The pre-intercalated powder obtained in step (2) is sent into the disc jet mill, which is provided with eight working nozzles, each of which is sprayed into the working cavity at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com