Gluing device

A technology of sizing rollers and adjusting devices, which is applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of low degree of automation and poor pertinence of sizing devices, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the content of the present invention is further explained below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

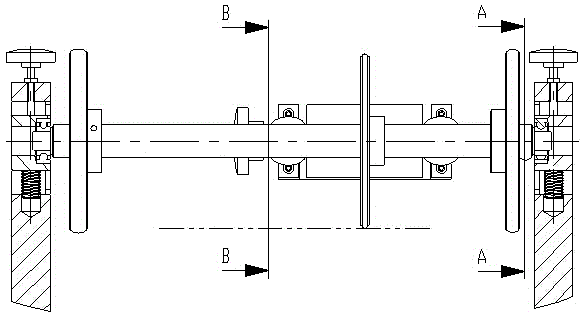

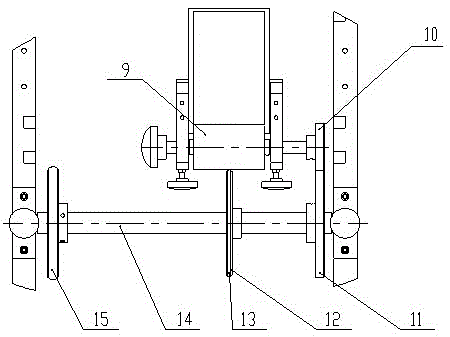

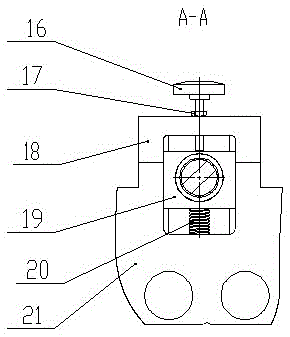

[0021] Such as Figure 1-4 As shown, the sizing device includes a bracket 21, a shaft 14, a first gear 11, a second gear 15, a sizing wheel 12, a glue box 1, a sizing roller 9, a sizing roller bracket 2, a third gear 10, an application Rubber roller shaft; the shaft 14 is set on the bracket 21 through bearings, the first gear 11, the second gear 15 and the sizing wheel 12 are all sleeved on the shaft 14, and the outer edge of the sizing wheel 12 is nested with sizing ring 13; the sizing roller 9 and the third gear 10 are sleeved on the sizing roller shaft, and the sizing roller shaft is arranged on the sizing roller bracket 2 through the first bearing 5, and the third gear 10 and the first gear 11 meshing, the glue box 1 is set on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com