Processing method of specially-shaped thick and thin Clip parts

A processing method and special-shaped technology, which is applied in the field of parts stamping processing, can solve problems such as affecting functions, failing to meet theoretical value requirements, and welding deviation, so as to reduce production costs, stabilize dimensions and various process parameters, and improve yield rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention discloses a method for processing special-shaped thick and thin Clip parts suitable for processing and manufacturing special-shaped thick and thin Clip parts.

[0026] A method for processing special-shaped thick and thin Clip parts, comprising the steps of:

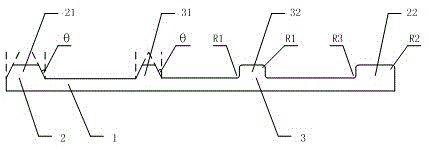

[0027] S1. Plate preparation steps: According to the processing needs, use the integrated calendering process to make corresponding special-shaped plates, such as figure 1 As shown, the special-shaped plate includes an integrally connected base part and a raised part, the base part is the substrate 1, and the raised part is arranged on the upper surface of the said substrate 1, including being arranged on the said substrate 1 Two sections of edge protrusions 2 on both sides, and two sections of central protrusions 3 arranged in the middle of the substrate 1;

[0028] S2. One-time stamping step: positioning the special-shaped plate, and after the positioning is completed, send the special-shaped plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com