A kind of visible light responsive silver phosphate composite photocatalyst and its preparation and application

A technology of silver phosphate and compound light, which is applied in the field of photocatalytic materials, can solve the problems of preventing visible light absorption and reducing photocatalytic performance, and achieves the effects of large-scale production, abundant raw materials, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

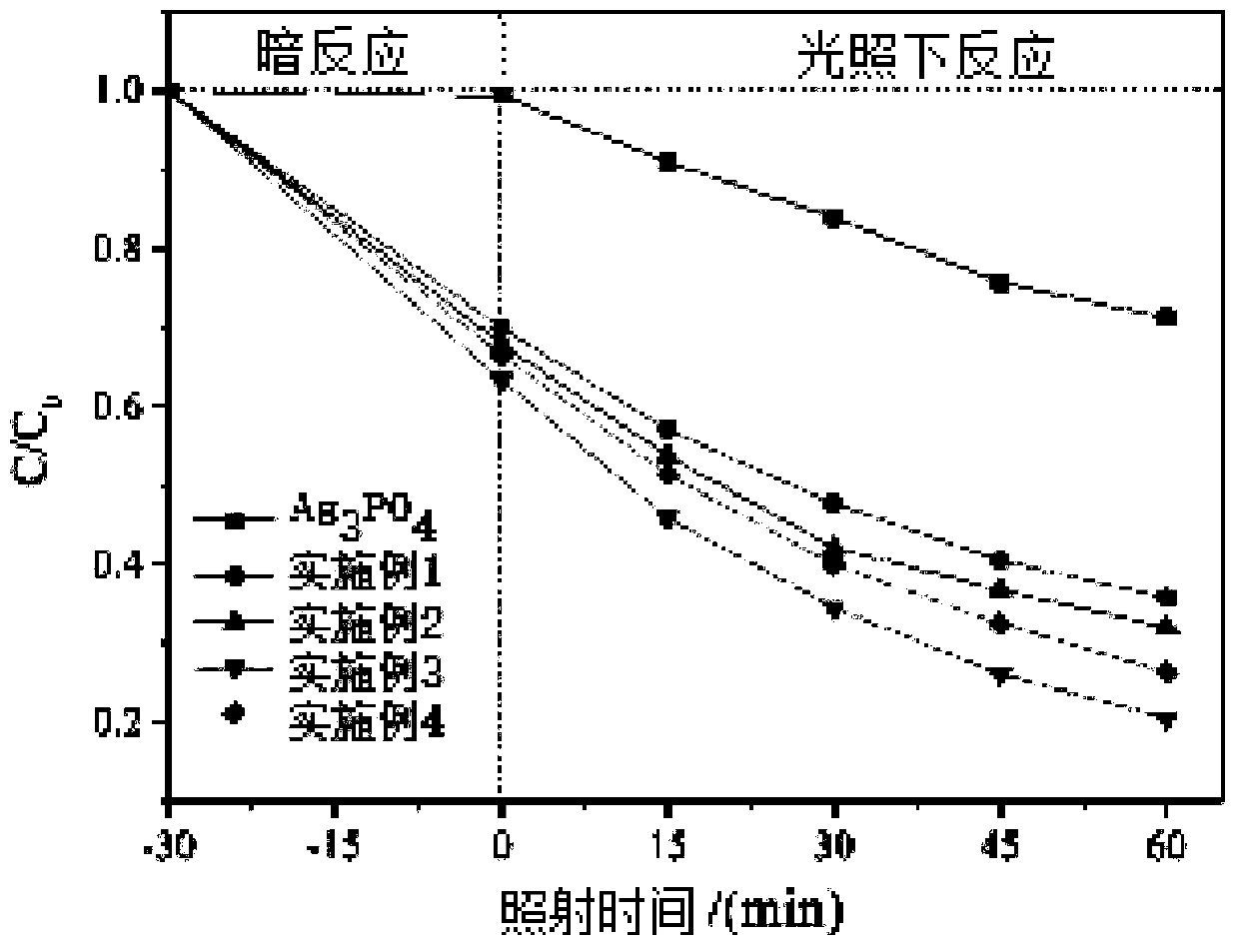

Embodiment 1

[0028] (1) Weigh CTAB, Na 2 SiO 3 and NH 4 h 2 PO 4 Add 0.034g, 0.17g, and 0.1725g to 30mL of water in sequence, and mix and stir at 500r / min for 40min at a constant temperature of 60°C.

[0029] (2) Weigh 0.34g AgNO 3 Dissolve in 10mL of water to make silver nitrate solution.

[0030] (3) The silver nitrate solution was added dropwise to the mixed solution in step (1), and stirred at a constant temperature of 60° C. at a speed of 500 r / min for 1 h.

[0031] (4) The obtained precipitate was centrifuged, washed alternately with distilled water and absolute ethanol, and dried in a vacuum oven at 60° C. for 12 hours to obtain a silver phosphate composite photocatalyst responding to visible light.

Embodiment 2

[0033] (1) Weigh CTAB, Na 2 SiO 3 and NH 4 h 2 PO 4 Add 0.034g, 0.17g, and 0.1725g to 30mL of water in sequence, and mix and stir at 500r / min for 40min at a constant temperature of 60°C.

[0034] (2) Weigh 0.34g AgNO 3 Dissolve in 10mL of water to make silver nitrate solution.

[0035] (3) Weigh 0.0017g of polythiophene and disperse it in the mixed liquid described in step (1).

[0036] (4) The silver nitrate solution was added dropwise to the mixed solution in step (3), and stirred at a constant temperature of 60° C. at a speed of 500 r / min for 1 h.

[0037] (5) The obtained precipitate was centrifuged, washed alternately with distilled water and absolute ethanol, and dried in a vacuum oven at 60° C. for 12 hours to obtain a silver phosphate composite photocatalyst responding to visible light.

Embodiment 3

[0039] (1) Weigh CTAB, Na 2 SiO 3 and NH 4 h 2 PO 4 Add 0.034g, 0.17g, and 0.1725g to 30mL of water in sequence, and mix and stir at 500r / min for 40min at a constant temperature of 60°C.

[0040] (2) Weigh 0.34g AgNO 3 Dissolve in 10mL of water to make silver nitrate solution.

[0041] (3) Weigh 0.0034g of polythiophene and disperse it in the mixed liquid described in step (1).

[0042] (4) The silver nitrate solution was added dropwise to the mixed solution in step (3), and stirred at a constant temperature of 60° C. at a speed of 500 r / min for 1 h.

[0043] (5) The obtained precipitate was centrifuged, washed alternately with distilled water and absolute ethanol, and dried in a vacuum oven at 60° C. for 12 hours to obtain a silver phosphate composite photocatalyst responding to visible light.

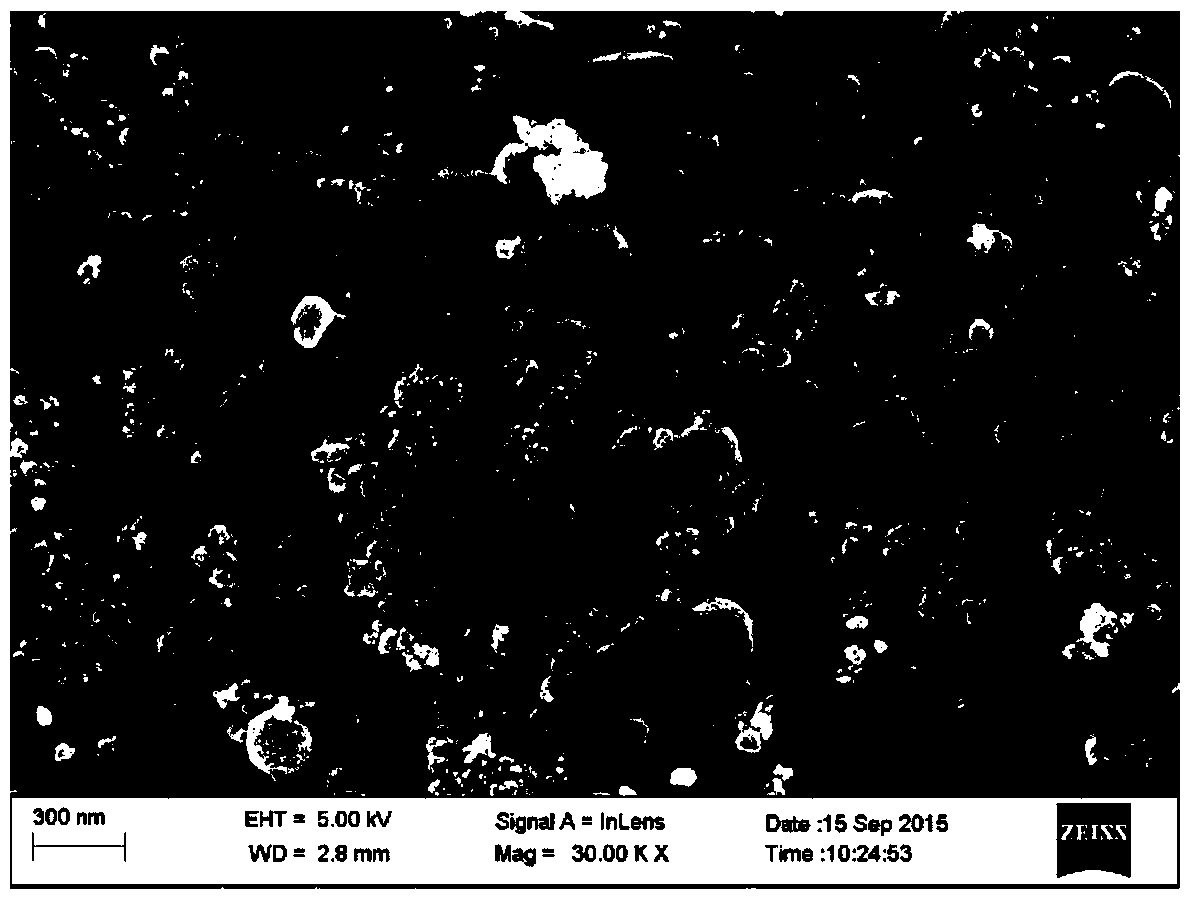

[0044] The scanning electron micrograph of the silver phosphate composite photocatalyst of the visible light response of the obtained embodiment is as follows figure 1 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com