A polyaniline hollow microsphere/zinc composite positive electrode material and button lithium battery

A composite positive electrode material, polyaniline technology, applied in the direction of battery electrodes, secondary batteries, secondary battery manufacturing, etc., can solve the problems of performance degradation, volume expansion, low capacity, etc., to improve conductivity, reduce AC impedance, specific The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

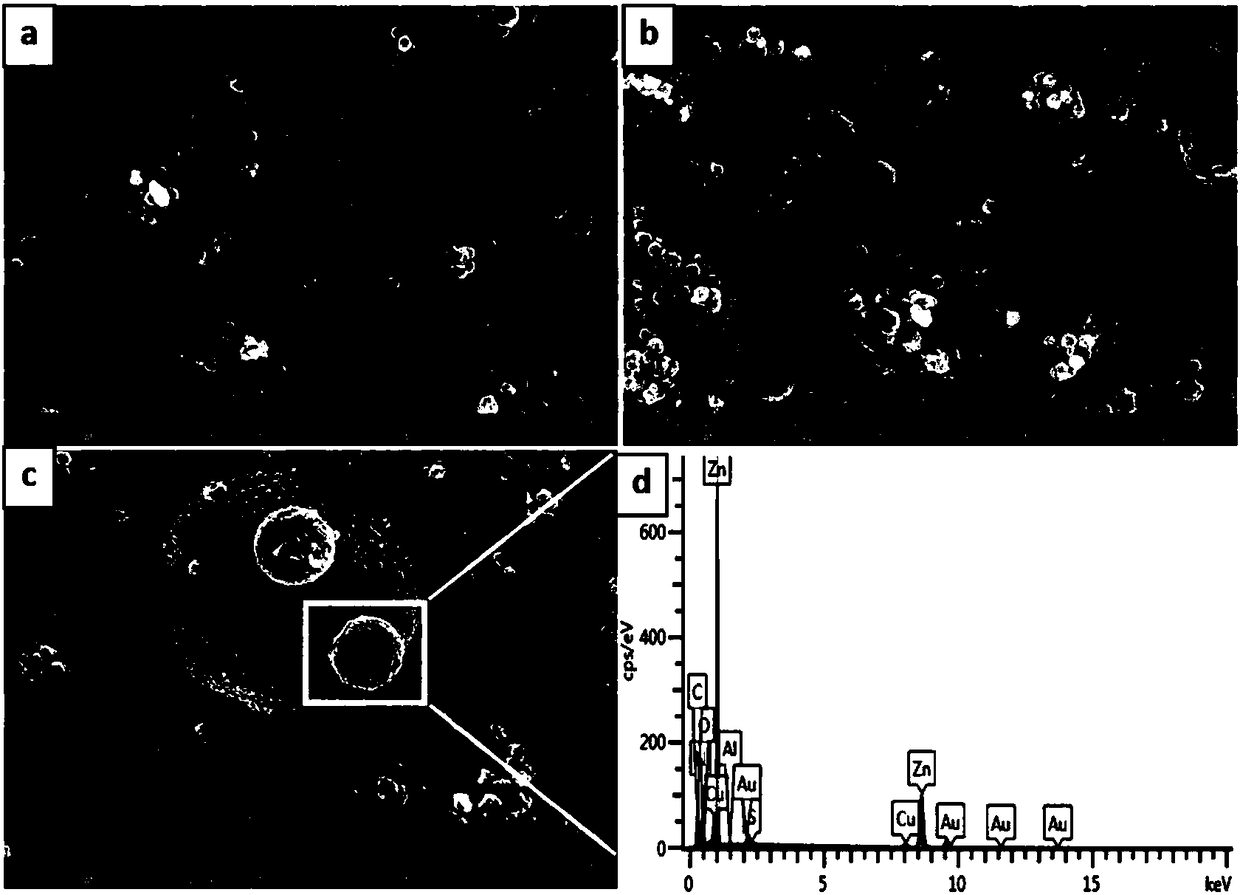

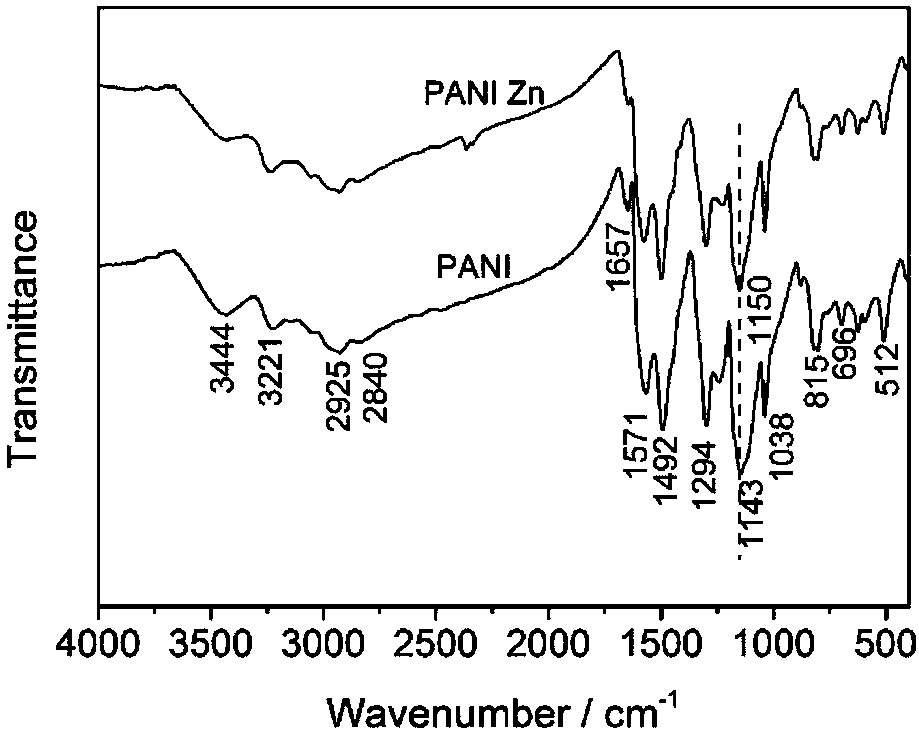

Embodiment 1

[0039] Take 6.32g of absolute ethanol, 72.00g of water, and 2.08g of an aqueous solution containing poly(2-acrylamido-2-methylpropanesulfonic acid) (referred to as PAMPS, with a mass fraction of 20%) into a 250mL beaker, and stir well . Subsequently, 1.86 g of aniline was added to the above mixture, and after ultrasonication for 10 minutes, the temperature of the above mixture containing aniline was raised to 80° C., and magnetically stirred at this temperature for 10 minutes. Quickly add 40mL aqueous solution containing 4.56g of ammonium persulfate at 80°C to the above mixed solution containing aniline, and react at a constant temperature of 80°C for 60s under stirring conditions. Subsequently, the reaction system was placed in an ice-water bath at a temperature of 0-5° C. to continue the reaction for 12 h. The polyaniline hollow microspheres are obtained by using acetone to break the emulsion, washing with water and suction filtering. Microspherical zinc powder and polyani...

Embodiment 2

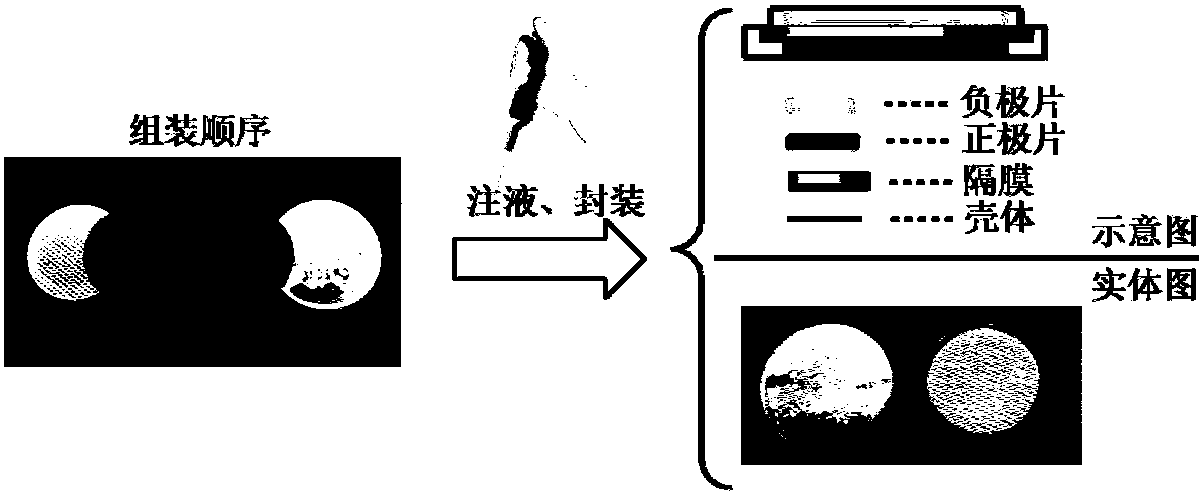

[0043] The polyaniline / zinc composite material that makes with embodiment 1 is used for the assembly of button type lithium battery:

[0044] Mix polyaniline hollow microspheres mixed with microspherical zinc powder, acetylene black, and polytetrafluoroethylene emulsion at a mass ratio of 80:10:10, add a small amount of absolute ethanol to adjust, and ultrasonicate for 10 minutes. Roll the ultrasonicated slurry into a thin sheet with a thickness of about 0.2mm, and press it on the nickel foam under an oil press. The pole piece was punched into a disc with a diameter of 15.0 mm using a die, and vacuum-dried at 70° C. for 12 hours to obtain a pole piece made of polyaniline material. Metal lithium sheets and polyaniline materials are used as the negative and positive electrodes of the battery respectively, with a separator in between, and 1mol / L LiPF 6 / EC+DMC as electrolyte, according to image 3 The form is assembled into a 2025-type button battery.

[0045] Figure 4 It sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com