Porous layer structure perovskite solar battery and preparation method thereof

A solar cell and perovskite-type technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of long preparation process, cost-effective competition, and high energy consumption in the preparation process, and achieve simple process, high coordination, and reliability good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

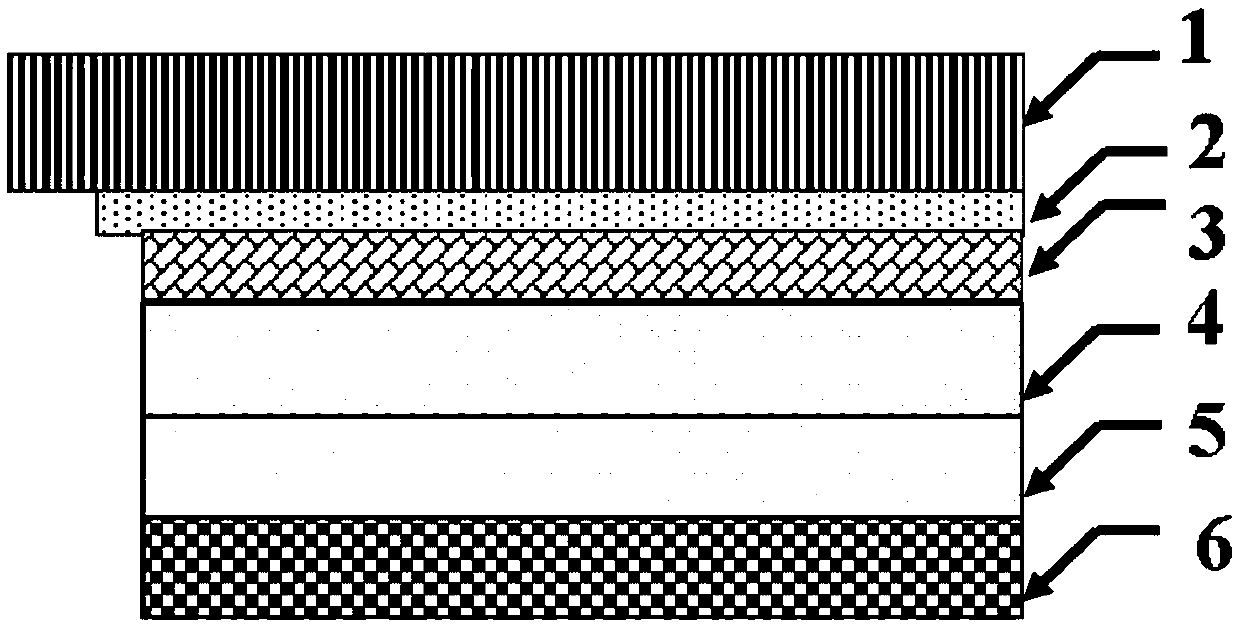

[0048] A method for preparing a perovskite solar cell with a porous layer structure, comprising the following steps:

[0049] 1. Select FTO glass with a sheet resistance of 12Ω and a transmittance of 75% as the FTO glass substrate 1, and then clean it with acetone and alcohol. The thickness of the FTO glass substrate is 100-150nm;

[0050] 2, the preparation of dense layer (same as step 2 of comparative example 1)

[0051] Put the weighed 109mg of ethylene glycol amine and 471mg of tetrabutyl titanate into a 20ml screw bottle, then add 10ml of ethanol, then place the screw bottle on a magnetic stirrer for 12h, and finally age for 24h. Solution A is obtained. Take an appropriate amount of solution A and drop it on the FTO glass substrate 1, then spin coat it at a rate of 2000-5000r for 40s, and anneal the obtained film at 500°C for 30min to obtain TiO 2 Dense layer 2; TiO 2 The thickness of the dense layer is 20-80nm.

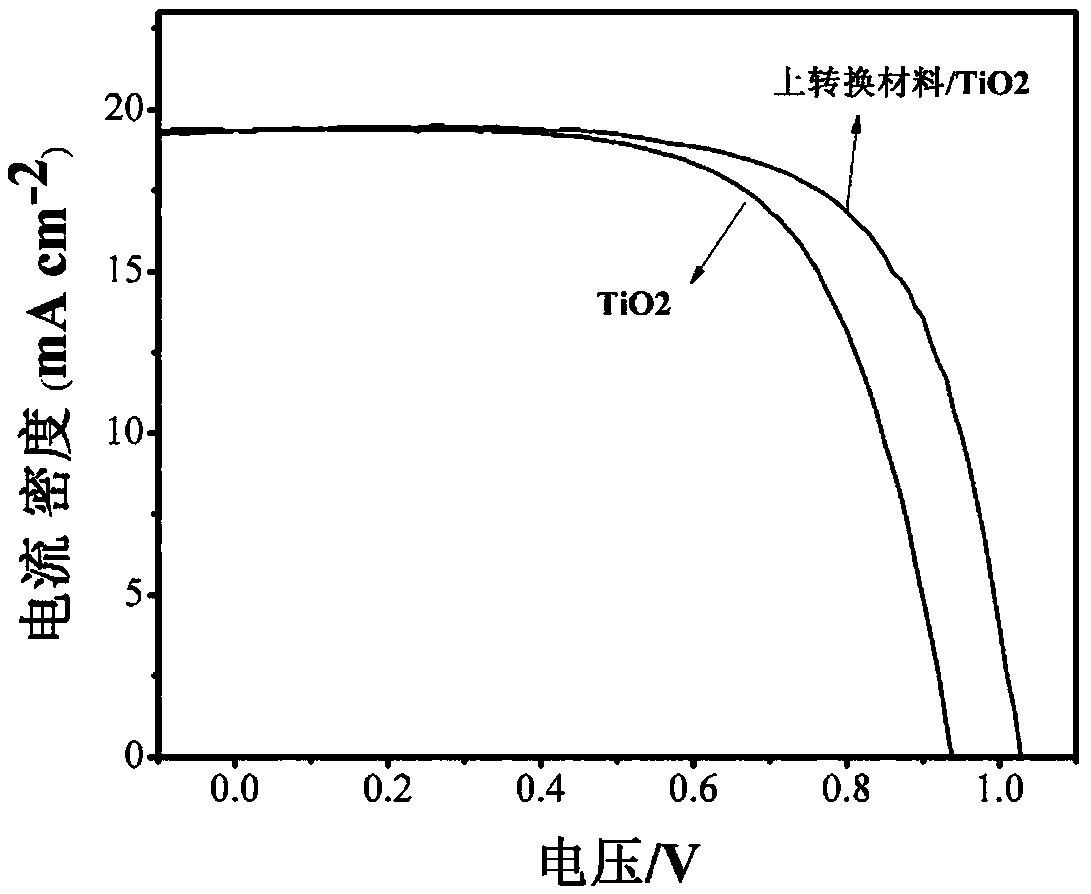

[0052] 3. Up-conversion luminescent material / TiO 2 P...

Embodiment 2

[0064] A method for preparing a perovskite solar cell with a porous layer structure, comprising the following steps:

[0065] 1. Select FTO glass with a sheet resistance of 12Ω and a transmittance of 75% as the FTO glass substrate 1, and then clean it with acetone and alcohol.

[0066] 2, the preparation of dense layer (same as step 2 of comparative example 1)

[0067] 3. Up-conversion luminescent material / TiO 2 Preparation of mixture porous layer

[0068] NaYF 4 is the matrix upconversion material (NaYF 4 : Yb with a stoichiometric ratio of 2% 3+ , with a stoichiometric ratio of 0.5% Er 3+ ) and titanium dioxide P25 in a weight ratio of 1:4 to obtain mixture A; ethyl cellulose, terpineol and alcohol in a weight ratio of 1:3:20 to obtain sol B; put sol B in 10ml Then pour mixture A into the bottle, the mass ratio of mixture A to sol B is 1:300. Seal the screw bottle and place it on a magnetic stirrer for more than 12 hours to continue stirring, and then sonicate for 8 h...

Embodiment 3

[0078] A method for preparing a perovskite solar cell with a porous layer structure, comprising the following steps:

[0079] 1. Select FTO glass with a sheet resistance of 12Ω and a transmittance of 75% as the FTO glass substrate 1, and then clean it with acetone and alcohol.

[0080] 2, the preparation of dense layer (same as step 2 of comparative example 1)

[0081] 3. Up-conversion luminescent material / TiO 2 Preparation of mixture porous layer

[0082] NaYF 4 is the matrix upconversion material (NaYF 4 : Yb with a stoichiometric ratio of 2% 3+ , with a stoichiometric ratio of 0.5% Ho 3+ ) and titanium dioxide P25 in a weight ratio of 8:4 to obtain a mixture A; mix ethyl cellulose, terpineol, and alcohol in a weight ratio of 1:2:20 to obtain a sol B; put sol B in 10ml Then pour mixture A into the bottle, the mass ratio of mixture A to sol B is 1:400. After sealing the screw bottle, place it on a magnetic stirrer for more than 12 hours and continue to stir for more th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com