Method for on-line monitoring of preparation of copper indium gallium selenide absorption layer

A copper indium gallium selenide and absorption layer technology, which is applied in the field of online monitoring for preparing a copper indium gallium selenide absorption layer, can solve the problems of limited scope, unrealistic wide application, and difficulty in obtaining a CIGS film with uniform and high crystalline quality. Achieve the effect of improving performance, yield, and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

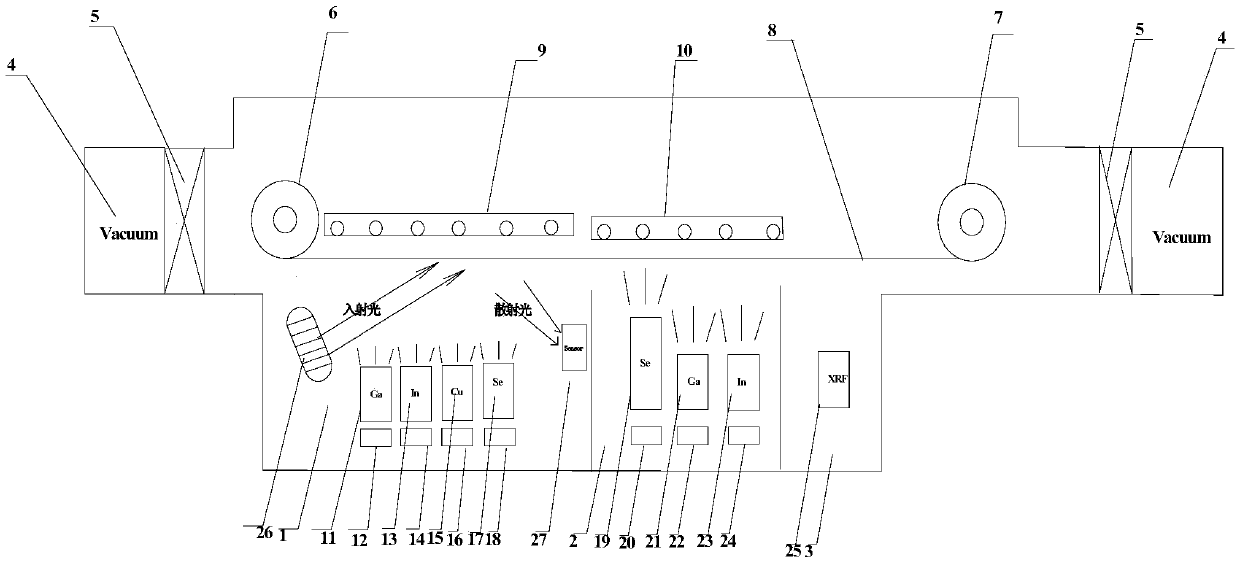

[0027] Example 1 roll-to-roll deposition of large-area CIGS thin films on flexible substrates, see figure 1 .

[0028] The flexible substrate includes metal foil, such as Ti foil, stainless steel sheet, Cu foil, etc., and the thickness of the substrate is 50-100 μm; or it is a plastic substrate, such as polyimide (PI), and the thickness of the substrate is 25-50μm.

[0029] use figure 1 The device shown is in the shape of a rectangular parallelepiped as a whole, and is made of #316 stainless steel plate through seamless welding process; the water-cooling pipeline is seamlessly welded on the surface of the vacuum chamber, and the temperature of the cold water flowing in is about 20°C. The device includes three chambers, a vacuum valve and a vacuum system. The vacuum system 4 is located at both ends of the device, and is used to maintain the vacuum degree of the chamber when the device is coated. A vacuum valve 5 is installed between the first and third chambers and the vacu...

Embodiment 2

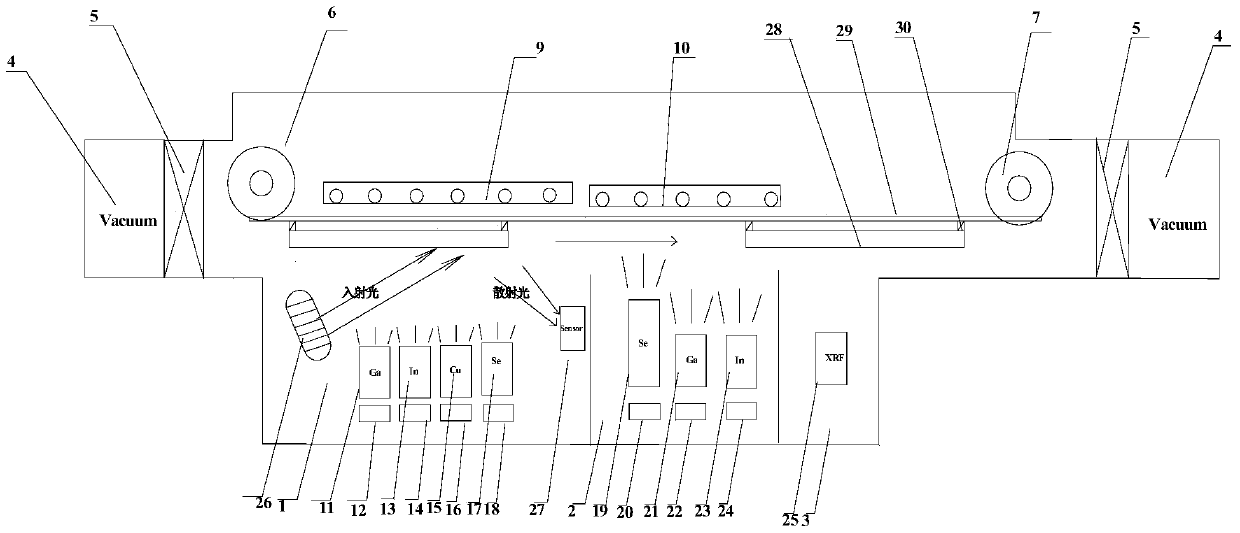

[0035] Embodiment 2 continuously vaporizes and deposits a large area CIGS thin film on a glass substrate, see figure 2 .

[0036] A co-evaporation process is used to continuously deposit a large-area CIGS absorbing layer on the glass substrate / Mo thin film, and the thickness of the glass substrate is 1-3mm. use figure 2The setup shown deposits large area CIGS thin films. The device includes three deposition chambers, a vacuum valve and a vacuum system. The main structure, constituent materials and cooling system of the device are the same as those described in Example 1. The distribution of evaporation sources in the three chambers, the heating system, the temperature control system, the online monitoring device, and the location and layout of the X-ray fluorescence spectrometer are the same as those in Example 1. The difference is that a vapor chamber and a transmission device 29 are installed on the upper part of the first and second deposition chambers. The vapor cham...

Embodiment 3

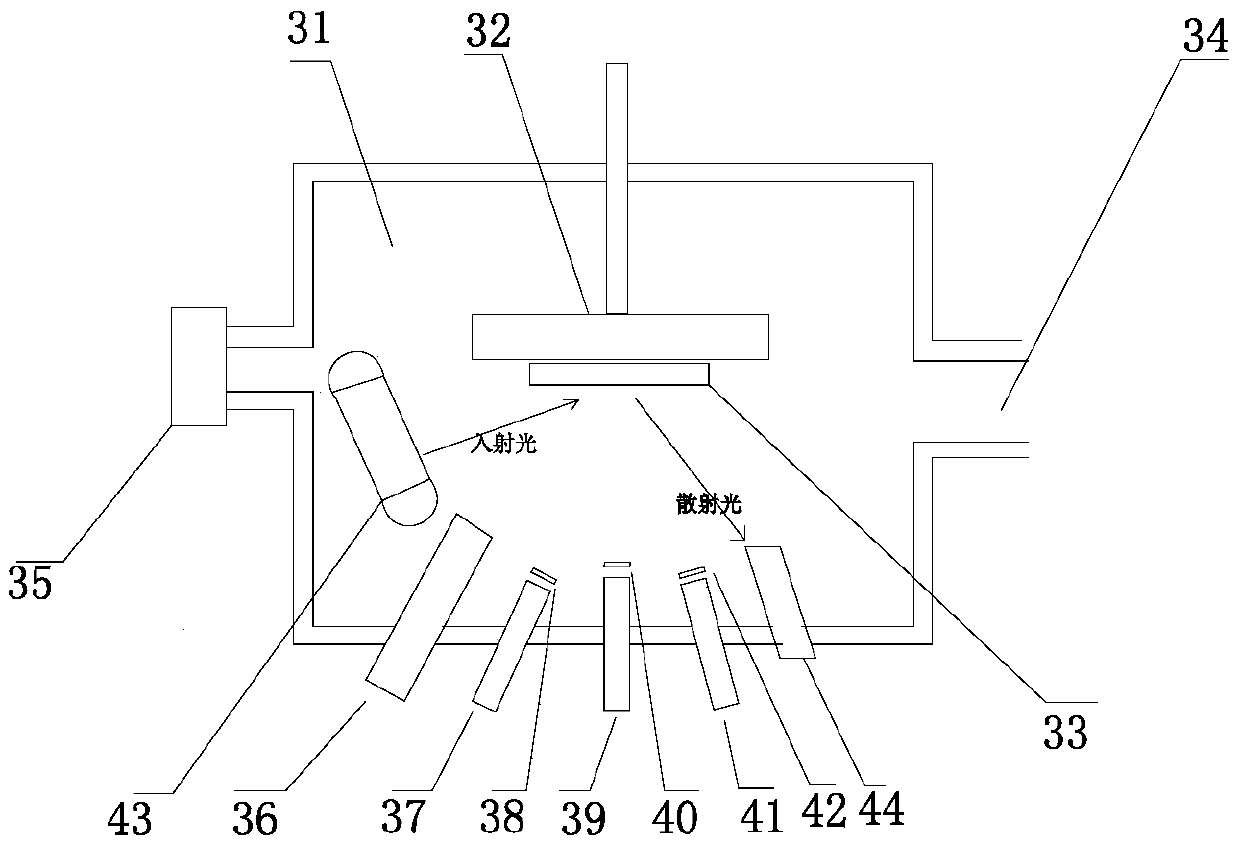

[0039] On-line monitoring and deposition equipment for preparing small-area CIGS thin films in the laboratory of embodiment 3, such as image 3 shown.

[0040] use image 3 The shown device adopts the co-evaporation three-step process to deposit CIGS thin films on flexible or rigid substrates, including flexible substrates such as polyimide and various metal foils, and rigid substrates such as glass . The substrate thickness is 0.05mm-3mm. image 3 The vacuum evaporation chamber 31 in the device is in the shape of a rectangular parallelepiped as a whole, and is made of #316 stainless steel plate through seamless welding process; a water-cooling pipeline is seamlessly welded on the surface of the vacuum chamber, and the temperature of the cold water flowing in is about 20°C. A vacuum pumping system 34 is arranged on the right side of the vacuum chamber, and an ionization gauge 35 is installed on the left side for testing the pressure of the chamber. A substrate heating syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com