Antireflection and self-cleaning thin film and preparation method thereof

A self-cleaning, anti-reflection technology, applied in final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve problems such as difficulty in adapting to wind sand, hail, solar panel surface contamination, and affecting the efficiency of battery modules. , to achieve good self-cleaning ability, degrade surface organic contamination, and improve the effect of capturing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

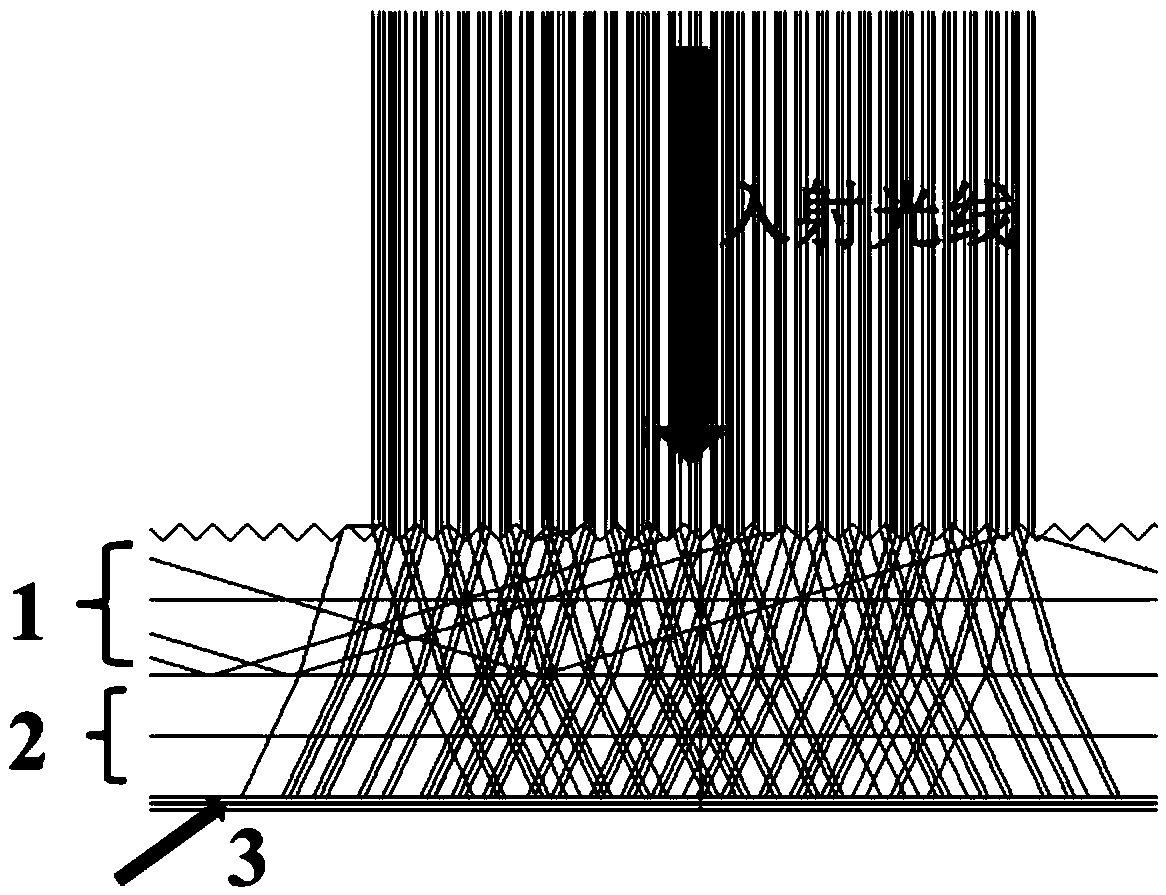

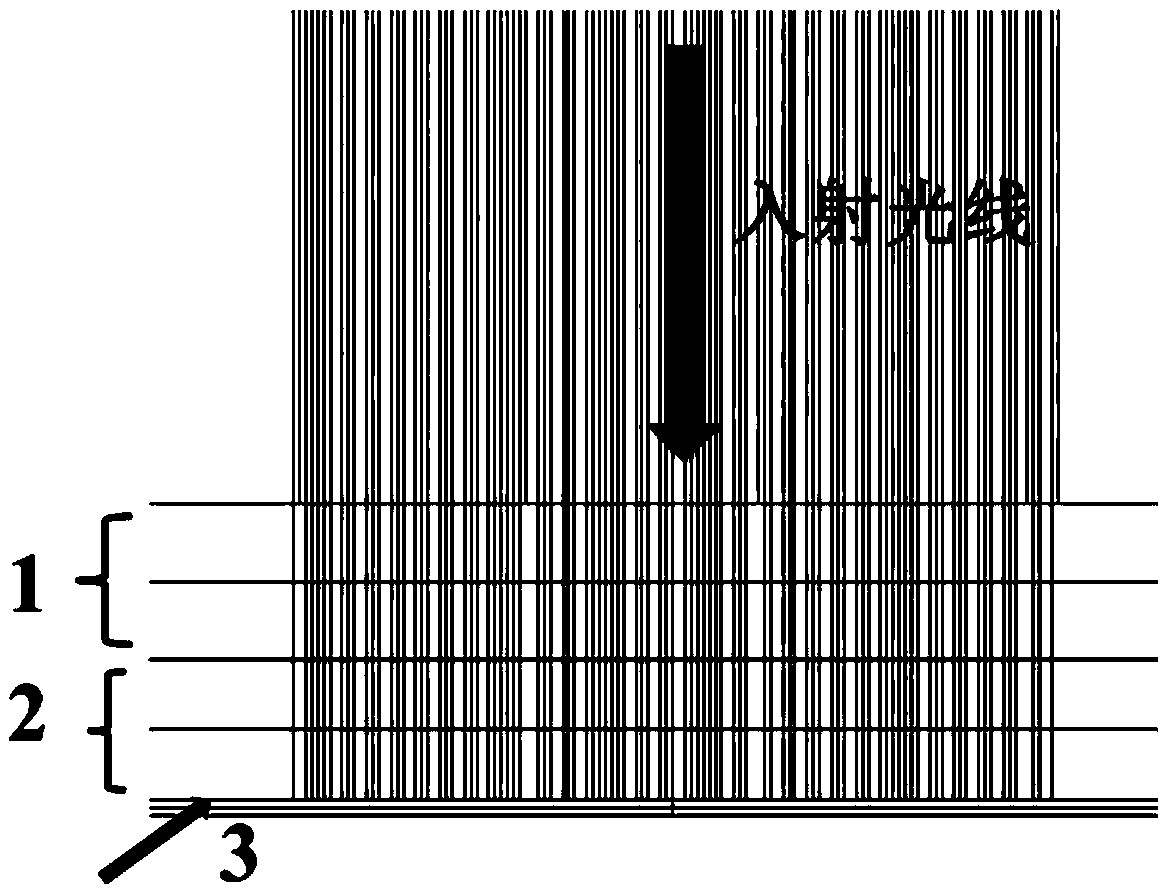

[0057] This embodiment provides a method for preparing an anti-reflection self-cleaning film, including: using imprinting technology and surface modification technology to process a three-dimensional pattern structure with a micron size on the transparent flexible film, so that the transparent flexible film has anti-reflection self-cleaning properties. Clean performance.

[0058] As an example, the embossing technology includes one of UV embossing, thermal embossing, thermal curing embossing, and micro-contact embossing, wherein the thermal embossing includes flat-bed embossing, roll-to-plate embossing, and A type of roll-to-roll embossing.

[0059] As an example, the UV embossing includes: coating a UV-curable glue on a transparent flexible film, then embossing the cured glue with a mold with a micron structure pattern, and separating the template from the substrate after being irradiated and cured by a UV lamp, that is Obtain the anti-reflection self-cleaning film.

[0060...

Embodiment 2

[0097] This embodiment provides a method for preparing an anti-reflection self-cleaning film, wherein, in this embodiment, the preparation process of the anti-reflection self-cleaning film prepared by a two-step hot pressing method is as follows:

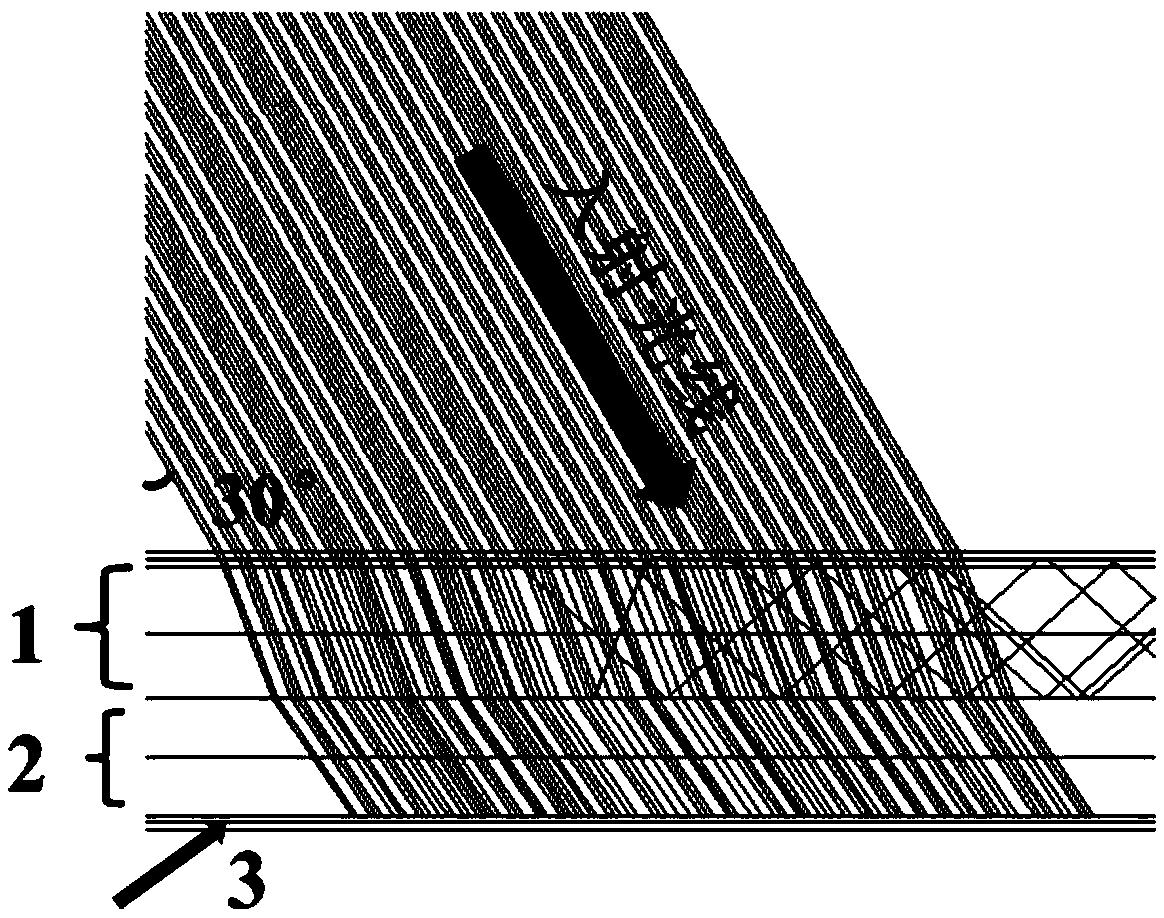

[0098] Step 1), the clean ETFE film is embossed by means of roll-to-roll or roll-to-plate hot pressing, the hot pressing temperature is 120°C, and the surface structure of the roller is jagged (sawtooth period is 50 μm, height is 30 μm), The pressure between the two rollers is 10MPa, and the temperature and pressure of the instrument reach the set value.

[0099] Step 2), preheat the clean ETFE film on a heating plate at 50°C for 15s, and roll it at a speed of 7m / min to obtain an anti-reflection self-cleaning film, such as Figure 5c shown.

[0100] Step 3), the anti-reflection self-cleaning film prepared in step 2) (specifically ETFE anti-reflection hydrophobic film), the fourth hot-melt adhesive, solar cell glass cover plate, the...

Embodiment 3

[0102] This embodiment provides a method for preparing an anti-reflection self-cleaning film, wherein, in this embodiment, the preparation process of the anti-reflection self-cleaning film prepared by a two-step hot pressing method is as follows:

[0103] Step 1), use roll-to-roll or roll-to-plate hot pressing to emboss the clean ETFE film, the hot pressing temperature is 120°C, and the structure of the roller surface is sawtooth (the sawtooth period is 50 μm, and the height is 25 μm), The pressure between the two rollers is 10MPa, and the temperature and pressure of the instrument reach the set value.

[0104] Step 2), preheat the clean ETFE on a heating plate at 50°C for 15s, and roll it at a speed of 7m / min to obtain an anti-reflection self-cleaning film, such as Figure 5c shown.

[0105] Step 3), the backboard material (polyester film with waterproof vapor performance, its structure is a three-layer film composite material, wherein, the lower film is a resin containing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com