A method of integrating embedded heat dissipation microchannels in ltcc ceramic substrates

A ceramic substrate and micro-channel technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as micro-channel deformation, achieve high production qualification rate, meet inter-layer interconnection and reliability requirements, and eliminate co-firing Effects of matching puzzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

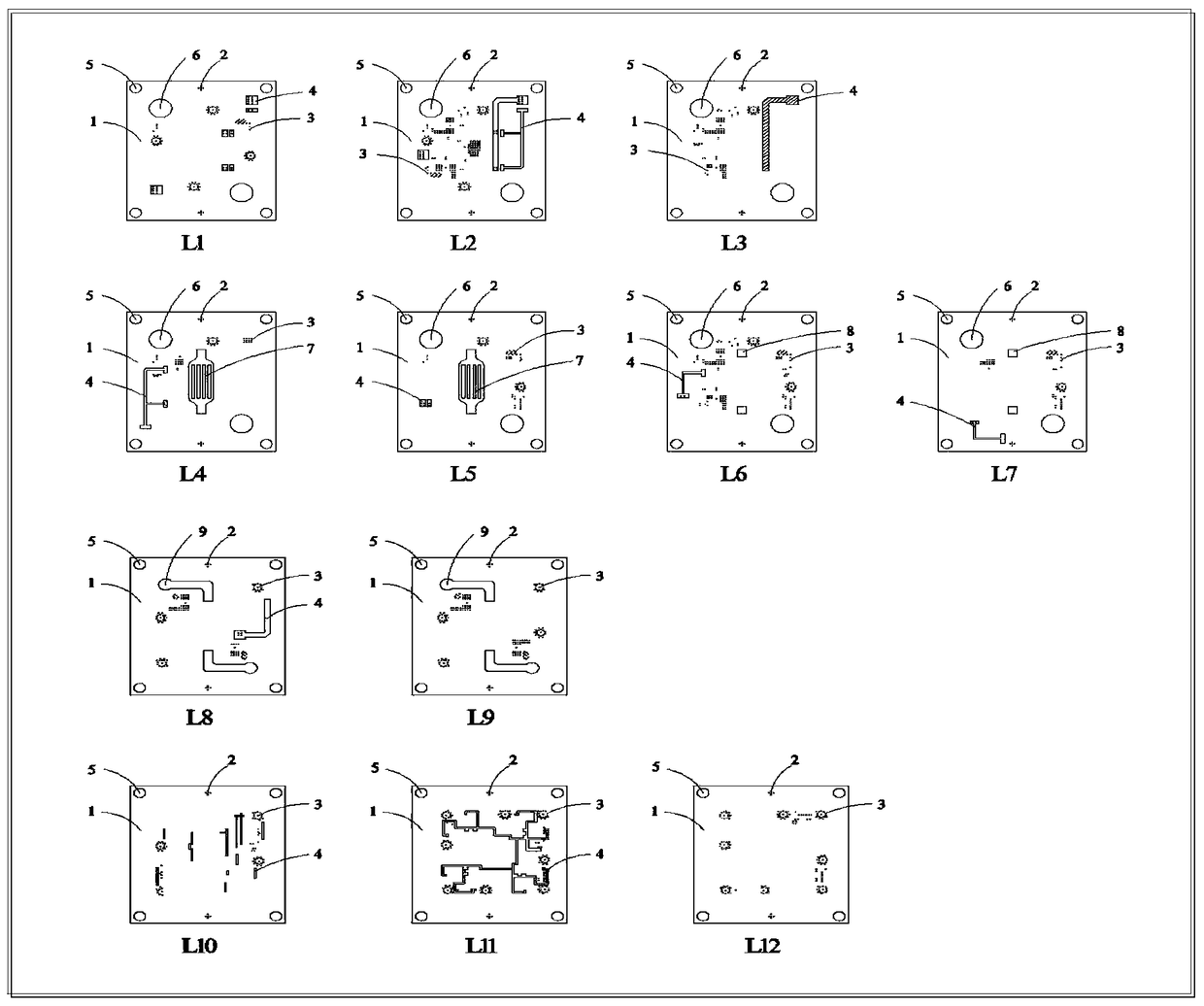

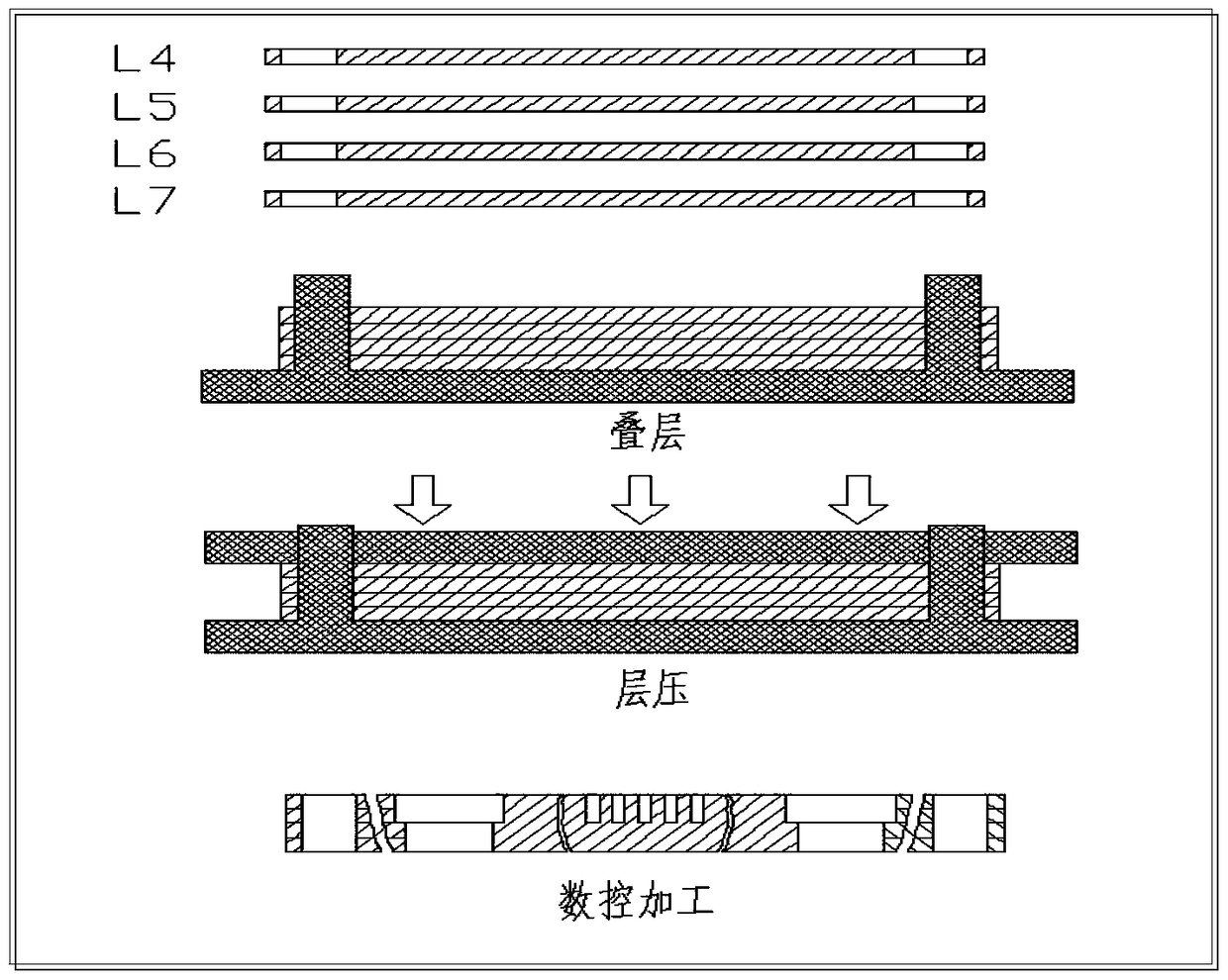

[0029] The following takes an LTCC ceramic substrate containing 12 layers of wiring as an example, and further describes it in conjunction with the accompanying drawings:

[0030] The adhesive used in the present invention, its main component is one of methyl methacrylate, ethyl methacrylate, polyvinyl butyral resin (PVB), polyvinyl chloride, etc., and its solvent is ethanol, acetone , butanone, butanol, toluene, trichlorethylene, cyclohexanone or one or more. For example: the main component is PVB, the solvent is butanone and butanol, and the weight ratio of the three is PVB: butanone: butanol = 5:90:5.

[0031] Such as figure 1 As shown, the LTCC ceramic substrate consists of a total of L 1 ~ L 12 There are 12 layers of green porcelain in total. In addition to specific alignment holes, interconnection holes and printed gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com