A kind of slurry for digital printing and its preparation method and application

A technology of digital printing and paste, applied in the fields of dyeing, textiles and papermaking, etc., it can solve the problems of not enough richness and pattern fineness, not enough pattern fineness, not enough richness, etc., to achieve bright colors and good quality Leveling performance and penetrating performance, the effect of improving the intensity of hair color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

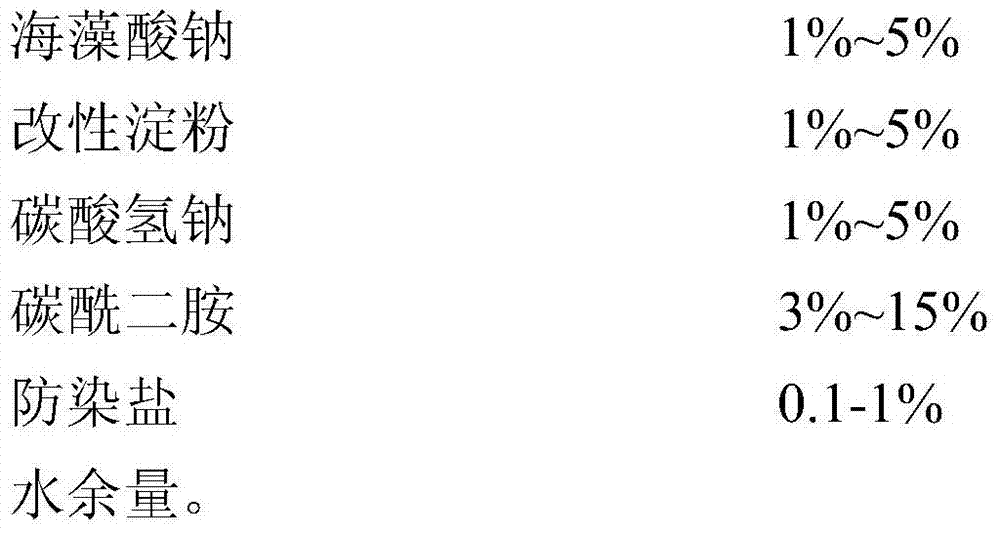

[0030] Slurry formula: 1% sodium alginate, 1% modified starch, 1% sodium bicarbonate, 3% carbonamide, 0.1% anti-staining salt S, 93.9% water.

[0031] The slurry preparation method is as follows:

[0032] Stir the sodium alginate into a paste first, then add sodium bicarbonate, stir to dissolve, then add the modified starch, and stir evenly to form the original paste; at room temperature, on the basis of the original paste, while stirring, slowly add carboxamide and anti-oxidant Dye with salt, stir for 50 minutes, and use it after standing for 24 hours.

[0033] The preparation method of modified starch is as follows:

[0034] Waxy cornstarch is dispersed in water to obtain starch milk (mass percentage concentration is 20%), then add sodium hydroxide to adjust the pH value of the starch milk to 8-10, then add dropwise octenyl succinic anhydride at 30°C Ethanol solution is reacted, and the mass percent concentration of octenyl succinic anhydride is 20%, wherein, during the re...

Embodiment 2

[0036] Slurry formula: 2% sodium alginate, 3% modified starch, 3% sodium bicarbonate, 12% carbonamide, 0.5% anti-staining salt S, 79.5% water.

[0037] Stir the sodium alginate into a paste first, then add sodium bicarbonate, stir to dissolve, then add the modified starch, and stir evenly to form the original paste; on the basis of the original paste, while stirring at room temperature, slowly add carboxamide and anti-oxidant Dye with salt, stir for 50 minutes, and use it after standing for 24 hours.

[0038] The preparation method of modified starch is as follows:

[0039] Waxy cornstarch is dispersed in water to obtain starch milk (mass percentage concentration is 25%), then add sodium hydroxide to adjust the pH value of the starch milk to 8-10, then add dropwise octenyl succinic anhydride at 40°C Ethanol solution is reacted, and the mass percent concentration of octenyl succinic anhydride is 10%, wherein, during the reaction, the pH value is kept between 8 and 10, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com