Cotton woven fabric scouring method based on trametes and white-rot fungus combined fermentation crude enzyme liquid

A crude enzyme solution and white rot fungus technology, which is applied in the biochemical treatment of enzymes/microorganisms, plant fibers, textiles and paper making, etc., can solve the problems of not meeting the requirements of wettability, different catalytic conditions, and limited types. , to achieve the effect of improving dyeing performance, reducing the number of washings, and saving the amount of dye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

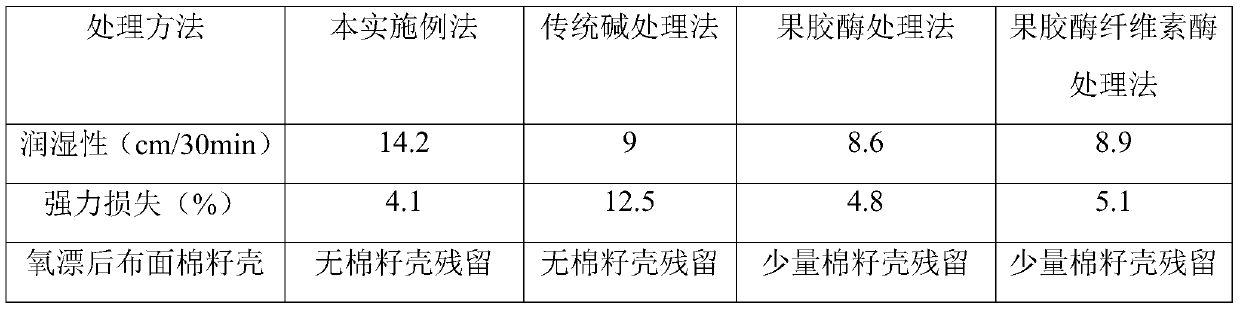

Image

Examples

Embodiment 1

[0032]Embodiment 1: the preparation method of composite crude enzyme liquid

[0033] (1) Trametes CGMCCNo.10489 and White Pythium In order to produce strains, spores (the ratio of the number of spores is about 1:5) are directly inserted into the liquid seed medium, and cultured at 28°C and 150r / min for 36h.

[0034] (2) With 10% (v / v) inoculum amount, insert the seed liquid into the fermentation medium and cultivate for 5 days to ferment and produce enzyme under the condition of 28°C and 150r / min; after the fermentation is finished, the fermentation liquid is centrifuged at 4000rpm for 30min, and the supernatant is taken The enzyme activity is measured, and the fermentation supernatant is the compound crude enzyme liquid.

[0035] Enzyme activity was measured to obtain laccase activity of 3080.8U / L, cellulase activity of 191U / L, hemicellulase activity of 16271.8U / L, pectinase activity of 16800U / L, lignin peroxidase activity of 2000U / L L.

Embodiment 2

[0036] Embodiment 2: the preparation method of composite crude enzyme liquid

[0037] Trametes CGMCCNo.10489 and white rot The spores (ratio of the number of spores is about 5:1) were inserted into the liquid seed medium, cultivated at 25°C and 180r / min for 40 hours to obtain the seed liquid, and then the seed liquid was inserted into the fermentation culture according to the inoculation amount of 12% by volume Base, cultured at 25°C and 180r / min for 6 days to ferment for enzyme production, centrifuged after fermentation to get the supernatant, which was the compound crude enzyme solution.

[0038] Take the supernatant to measure the enzyme activity, laccase activity 3298.2U / L, cellulase activity 182U / L, hemicellulase activity 15971.8U / L, pectinase activity 15960U / L, lignin peroxidation Physical enzyme 1880U / L.

Embodiment 3

[0039] Embodiment 3: the preparation method of composite crude enzyme liquid

[0040] Trametes CGMCCNo.10489 and white rot The spores were inserted into the liquid seed medium, cultivated at 30°C and 120r / min for 32h to obtain the seed liquid, and then the seed liquid was inserted into the fermentation medium according to the inoculum amount of 8% by volume, and cultivated under the conditions of 30°C and 120r / min Under culture for 4 days to ferment for enzyme production, centrifuge after the end of fermentation to take the supernatant, which is the compound crude enzyme solution.

[0041] Take the supernatant to measure the enzyme activity, laccase activity 3302.1U / L, cellulase activity 183U / L, hemicellulase activity 15979.81U / L, pectinase activity 16422U / L, lignin peroxidation Physical enzyme 1928U / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com