Poria cocos cellulose fiber and preparation method thereof

A cellulose fiber and cellulose technology, applied in the field of Poria cocos cellulose fiber and its preparation, can solve the problems of rapid loss of effective substances, high rate of ultra-long fibers, large coefficient of variation of dry breaking strength, etc., and achieve good antibacterial effect , high blood sugar improvement, good avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

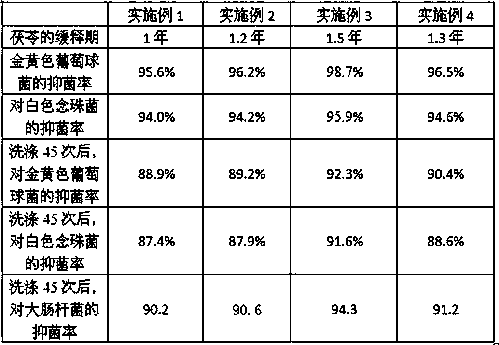

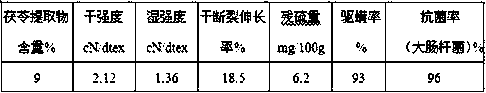

Embodiment 1

[0037] Embodiment 1 specification is the preparation method of the Poria cocos cellulose fiber of 1.11dtex*32mm

[0038] The preparation of step 1, Poria cocos microcapsules

[0039] (1) Selection of raw materials

[0040] Poria cocos extract is selected as the raw material of Poria cocos microcapsules. The poria cocos extract is a brown yellow powder, 100% of which passes through an 80 mesh sieve, the content of polysaccharides is 60%, the ash content is ≤3.2%, the water content is ≤3.8%, and the heavy metal Content ≤ 5ppm, lead content ≤ 1ppm, arsenic content ≤ 0.5ppm, mercury content ≤ 0.4ppm, total number of bacteria ≤ 500cfu / g, total number of mold ≤ 50cfu / g, Salmonella and Escherichia coli shall not be detected.

[0041] (2) Preparation of organic phase

[0042] Select carboxymethyl cellulose, ethyl cellulose, polyisocyanate, polyacrylic acid to make composition A and dissolve in isobutyl acetate solution, the carboxymethyl cellulose, ethyl cellulose, polyisocyanate, p...

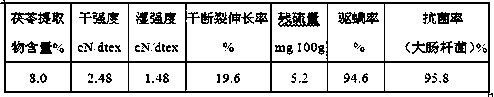

Embodiment 2

[0067] Embodiment 2 specification is the preparation method of the Poria cocos cellulose fiber of 1.33dtex*38mm

[0068] The preparation of step 1, Poria cocos microcapsules

[0069] (1) Selection of raw materials

[0070] Poria cocos extract is selected as the raw material of Poria cocos microcapsules. The poria cocos extract is a brownish yellow powder, 100% of which passes through an 80 mesh sieve, and the content of poria cocos polysaccharide is 65%, the ash content≤3.5%, the moisture content≤3.3%, heavy metal Content ≤ 5ppm, lead content ≤ 1ppm, arsenic content ≤ 0.5ppm, mercury content ≤ 0.4ppm, total number of bacteria ≤ 500cfu / g, total number of mold ≤ 50cfu / g, Salmonella and Escherichia coli shall not be detected.

[0071] (2) Preparation of organic phase

[0072] Select carboxymethyl cellulose, ethyl cellulose, polyisocyanate, polyacrylic acid to make composition A and dissolve in isobutyl acetate solution, the carboxymethyl cellulose, ethyl cellulose, polyisocyana...

Embodiment 3

[0097] Embodiment 3 specification is the preparation method of the Poria cocos cellulose fiber of 1.67dtex*38mm

[0098] The preparation of step 1, Poria cocos microcapsules

[0099] (1) Selection of raw materials

[0100] Poria cocos extract is selected as the raw material of Poria cocos microcapsules. The poria cocos extract is a brown yellow powder, 100% of which passes through an 80 mesh sieve, the content of polysaccharides is 70%, the ash content is ≤2.8%, the water content is ≤3.2%, and the heavy metal Content ≤ 5ppm, lead content ≤ 1ppm, arsenic content ≤ 0.5ppm, mercury content ≤ 0.4ppm, total number of bacteria ≤ 500cfu / g, total number of mold ≤ 50cfu / g, Salmonella and Escherichia coli shall not be detected.

[0101] (2) Preparation of organic phase

[0102]Select carboxymethyl cellulose, ethyl cellulose, polyisocyanate, polyacrylic acid to make composition A and dissolve in isobutyl acetate solution, the carboxymethyl cellulose, ethyl cellulose, polyisocyanate, po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com