Epoxy-resin-modified UV (ultraviolet) raw lacquer ink for digital jet printing and preparation method thereof

An epoxy resin, digital printing technology, applied in the direction of ink, application, household appliances, etc., can solve the problems of long curing time, easy to block the nozzle, and spray out from the bottom, to achieve good paint film performance, improve paint film performance, The effect of high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the epoxy resin modified UV raw lacquer ink that is used for digital jet printing comprises the steps:

[0030] (1) First, extract urushiol from Ankang lacquer, Pingli lacquer, Chengkou lacquer, Maoba lacquer, Qinling lacquer or other raw lacquers in a three-necked flask with xylene at a mass ratio of 1:1, and take the supernatant after standing still. Liquid, obtain urushiol xylene solution;

[0031] (2) Put the urushiol xylene solution, formaldehyde, ammonia water, and polymerization inhibitor in the reaction kettle (the molar ratio of urushiol to formaldehyde is 0.85-0.9, ammonia water is the catalyst), and control the system temperature at 40-70°C for reaction 0.5-1h; After the reaction is completed, the temperature is raised for dehydration, and when the temperature reaches 136°C, the water is removed to obtain the urushiol formal polymer;

[0032] (3) Put the obtained urushiol formal and epoxy resin in equal proportions into the reaction...

Embodiment 1

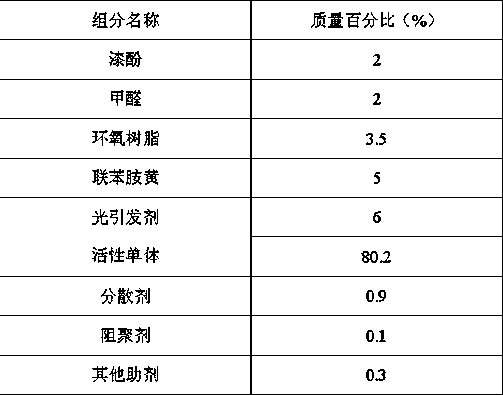

[0045] In the preparation process of a kind of epoxy resin modified UV raw lacquer ink for digital jet printing of the present embodiment, the mass percentage of each component is as follows:

[0046]

[0047] The other additives include catalysts, defoamers, stabilizers, photosensitizers, leveling agents, and the ratio is 1:1.

Embodiment 2

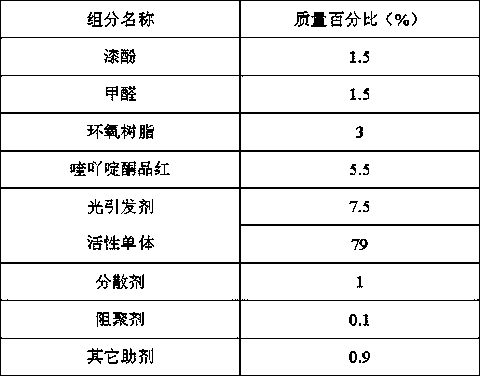

[0049] In the preparation process of a kind of epoxy resin modified UV raw lacquer ink for digital jet printing of the present embodiment, the mass percentage of each component is as follows:

[0050]

[0051] The other additives include catalysts, defoamers, stabilizers, photosensitizers, leveling agents, and the ratio is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com