nylon composite

A nylon composite material and nylon technology, applied in the field of nylon composite materials, can solve problems such as insignificant reinforcement effect, decreased gloss, and large equipment loss, and achieve the goal of overcoming poor dimensional stability of materials, improving strength and toughness, and reducing loss costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Also provide a kind of preparation method of nylon composite material in one embodiment of the present invention, comprise the steps:

[0031] S110, weighing and drying the raw materials according to the above weight percentage, wherein the drying condition of the nylon resin is 4-8 hours at 80-100°C;

[0032] S120. Evenly mix the dried nylon resin, modified nano boehmite, compatibilizer, lubricant and antioxidant into the hopper of the twin-screw extruder, and feed it in the side of the twin-screw extruder Add chopped glass fiber at the feed port and extrude;

[0033] For example, add the dried nylon resin, modified nano-boehmite, compatibilizer, lubricant and antioxidant into a high-speed mixer and mix for 15-20 minutes to mix the raw materials evenly before adding them to the twin-screw extruder.

[0034] Specifically, the process conditions of the twin-screw extruder are set as follows: the temperature of the first zone is 200-220°C, the temperature of the second z...

Embodiment 1

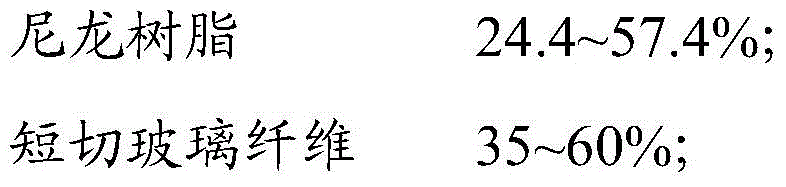

[0049] Nylon composite material in the embodiment of the present invention 1 comprises the following components in the following weight percentages:

[0050] Nylon 6: 57.4%, chopped glass fiber: 35%, modified nano boehmite: 5%, compatibilizer: 2%, lubricant: 0.3%, antioxidant: 0.3%.

[0051] The preparation method of nylon composite material in the embodiment of the present invention 1, comprises the following steps:

[0052] Nylon 6 was dried at 100°C for 6 hours, and nano-mica was dried at 100°C for 8 hours. Stir the dried nylon 6, modified nano-boehmite, compatibilizer, lubricant, and antioxidant in a high-speed mixer for 3 minutes, then add it to the hopper of the twin-screw extruder, and put it on the side of the twin-screw extruder Add chopped glass fiber to the feed opening. The process conditions of the twin-screw extruder are set as follows: the temperature of the first zone is 200-220°C, the temperature of the second zone is 220-240°C, the temperature of the third ...

Embodiment 2

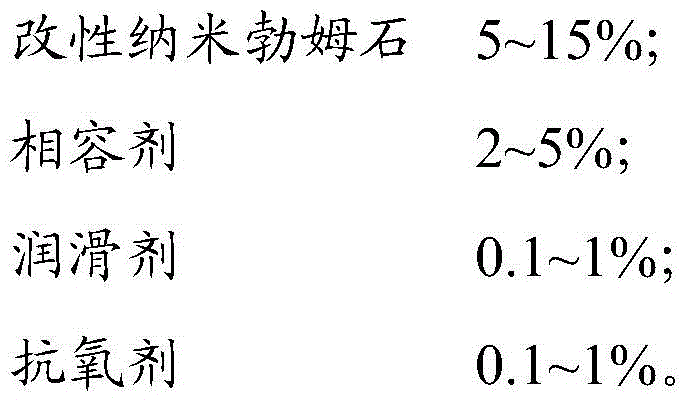

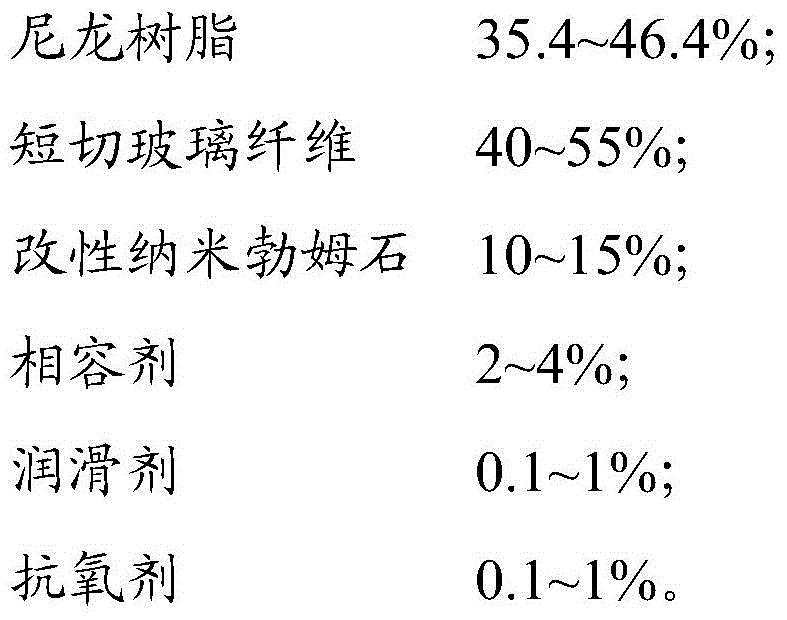

[0054] The glass fiber reinforced nylon composite material in Example 2 of the present invention includes the following components in weight percentage:

[0055] Nylon 6: 46.4%, chopped glass fiber: 35%, modified nano boehmite: 15%, compatibilizer: 3%, lubricant: 0.3%, antioxidant: 0.3%.

[0056] The preparation method of the glass fiber reinforced nylon composite material in Example 2 of the present invention is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com