Anti-cracking high-performance concrete and preparation method thereof

A high-performance concrete, anti-cracking technology, applied in the field of concrete, can solve the problems of decreased mechanical properties, low apparent density, insufficient strength, etc., and achieve the effects of improving overall performance, increasing binding capacity, and being easy to disperse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

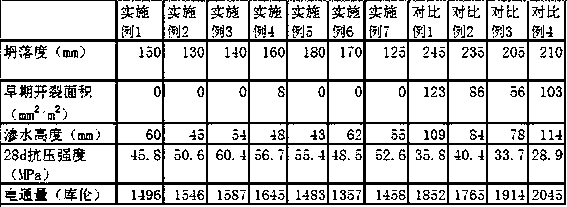

Examples

preparation example Construction

[0036] The preparation method of concrete of the present invention is:

[0037] Step 1: Add porous granular aggregate, layered silicate minerals, water-reducing retarder, and bentonite to the cement, stir for 30 minutes, add air-entraining agent and continue stirring for 30 minutes, and then divide the obtained mixture into 5 : two parts of mix I and mix II of 3;

[0038] Step 2: Epoxy resin emulsion, alkali-resistant glass fiber and polyethylene oxide are added in the mixture I, and stirred for 40 minutes;

[0039] Step 3: Add the curing agent into the mixture II, and stir thoroughly for 30 minutes;

[0040] Step 4: Mix Mixture I and Mixture II, and then stir thoroughly for 30 minutes, and then put them into a mold for molding.

[0041] The embodiments of the present invention are all prepared by the above method, wherein the quality of each substance adopts the numerical value in the specific embodiment.

[0042] experiment method:

[0043] According to the concrete perf...

Embodiment 1

[0045] The concrete of the present embodiment comprises following parts by weight material:

[0046] Cement 7kg;

[0048] Sodium dodecylbenzenesulfonate 0.05kg;

[0049] Bentonite 0.5kg;

[0050] Water-reducing retarder 0.3kg;

[0051] Vitrified microbeads 4kg;

[0052] Alkali-resistant glass fiber 0.35kg;

[0053] Polyethylene oxide 0.03kg;

[0054] Epoxy resin emulsion 1.3kg;

[0055] Aminoethylpiperazine 0.6kg.

Embodiment 2

[0057] The concrete of the present embodiment comprises following parts by weight material:

[0058] Cement 8.5kg;

[0060] Sodium dodecylbenzenesulfonate 0.06kg;

[0061] Bentonite 0.3kg;

[0062] Water-reducing retarder 0.02kg;

[0063] Vitrified microbeads 6kg;

[0064] Alkali-resistant glass fiber 0.5kg;

[0065] Polyethylene oxide 0.05kg;

[0066] Epoxy resin emulsion 1kg;

[0067] Aminoethylpiperazine 0.5kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com