Carbon aerogel prepared from chitin aerogel and preparation method thereof

A technology of carbon airgel and chitin, applied in the field of carbon airgel and its preparation, can solve the problems of low specific surface area and single hole of carbon airgel, achieve high porosity, increase use value, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

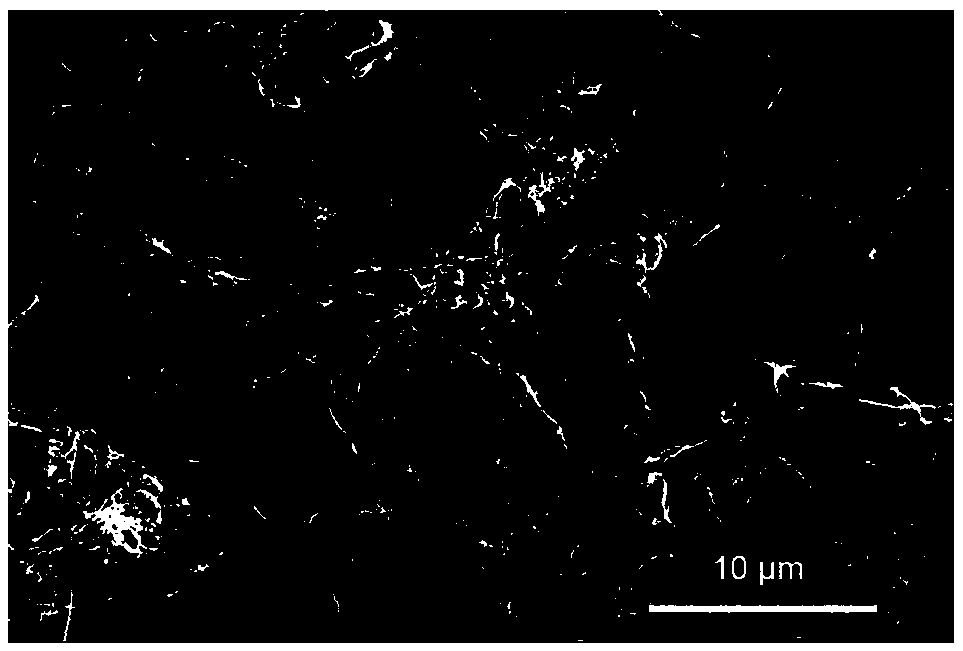

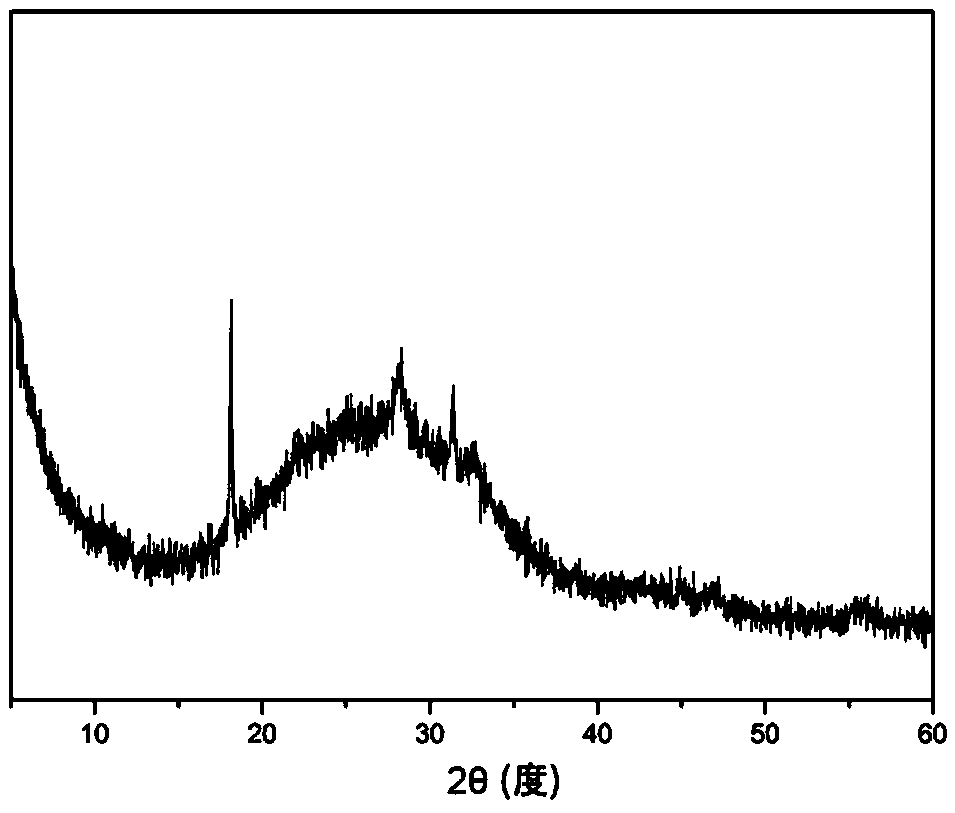

Image

Examples

Embodiment 1

[0041]1. Rinse the discarded shrimp shells, dry them and crush them through an 80-mesh sieve to obtain biomass powder;

[0042] 2. Take 1g of crushed shrimp skin, first use petroleum ether ethanol to extract at a ratio of 2:1, remove some organic matter, and purify the shrimp skin by KOH treatment to remove impurities such as protein, and then use glacial acetic acid to adjust pH = 4.5 and add 1wt%NaClO 2 Bleaching at 75°C for 2 hours;

[0043] 3. Prepare the bleached shrimp skin as a 1wt% dispersion, and obtain a 1wt% thick chitin dispersion by mechanical disc grinding;

[0044] 4. Add the phosphate buffer solution to the above dispersion liquid, adjust the pH of the dispersion liquid to 7, stir on a magnetic stirrer at 500 rpm, at room temperature and pressure for 10 min, to better disperse chitin;

[0045] 5. Then add TEMPO and NaClO, disperse evenly and then add NaClO 2 , TEMPO:NaClO:NaClO 2 The molar ratio is 1:10:100, and the container is quickly sealed and heated to...

Embodiment 2

[0051] 1. Rinse the industrially discarded crab shells, dry them, and crush them through an 80-mesh sieve to obtain crab shell powder; take 1g of the crushed crab shell powder, and first use benzene:ethanol to extract at a ratio of 2:1 to remove some organic matter. Then use NaOH treatment to remove impurities such as protein to purify the crab shells, and then use glacial acetic acid to adjust pH=4.5 by adding 1wt% NaClO 2 Bleached by heating at 75°C for 2 hours, then washed to neutrality, prepared as a 1wt% solution, and stored at 4°C;

[0052] 2. Take 400mL of the above dispersion, stir evenly, add 300mL of phosphate buffer solution with pH=6.8, adjust the pH of the dispersion to 6.8±0.2.

[0053] 3. Then add TEMPO and NaClO, disperse evenly and then add NaClO 2 , TEMPO:NaClO:NaClO 2 The molar ratio is 1:10:100, and the container is quickly sealed and heated to 80°C for 3 hours. After the reaction is completed, 20 mL of ethanol is added to terminate the reaction;

[0054...

Embodiment 3

[0059] 1. The industrial waste shrimp skin is crushed through an 80-mesh sieve to obtain the shrimp skin powder;

[0060] 2. Take 1g of crushed shrimp skin powder, first use phenylethanol to extract at a ratio of 2:1 to remove some organic matter, then use NaOH treatment to remove impurities such as protein to purify the shrimp skin, and then use glacial acetic acid to adjust the pH=4 condition Add 1.5wt% NaClO under 2 Heated at 80°C for 1.5h to bleach, then washed to neutrality, made into a 1wt% solution, and stored at 4°C;

[0061] 3. Take 400mL of the above dispersion liquid, stir it evenly, add TEMPO and NaBr directly, after the dispersion is even, add NaClO, the molar ratio of TEMPO:NaBr:NaClO is 1:10:30, react under stirring, use 0.1~5mol / L NaOH Control the pH of the dispersion at 10±0.2, react for 3 hours, add 20mL of ethanol to terminate the reaction;

[0062] 4. Repeatedly rinse the obtained dispersion with deionized water until it becomes neutral, and then use an u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com