Fuel pump production line

A fuel pump and production line technology, which is applied to liquid fuel feeders, assembly machines, mechanical equipment, etc., can solve the problems of production line safety hazards, poor assembly accuracy, and more manual participation, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings of the description.

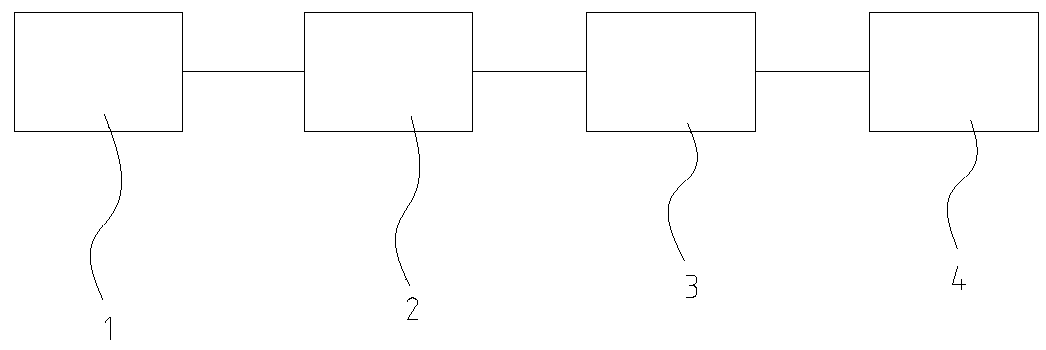

[0039] like figure 1 As shown, a fuel pump production line includes a magnetic tile precision assembly machine 1, an oil outlet pan assembly precision assembly machine 2, a pump body assembly precision assembly machine 3 and a pump core comprehensive performance precision testing machine 4.

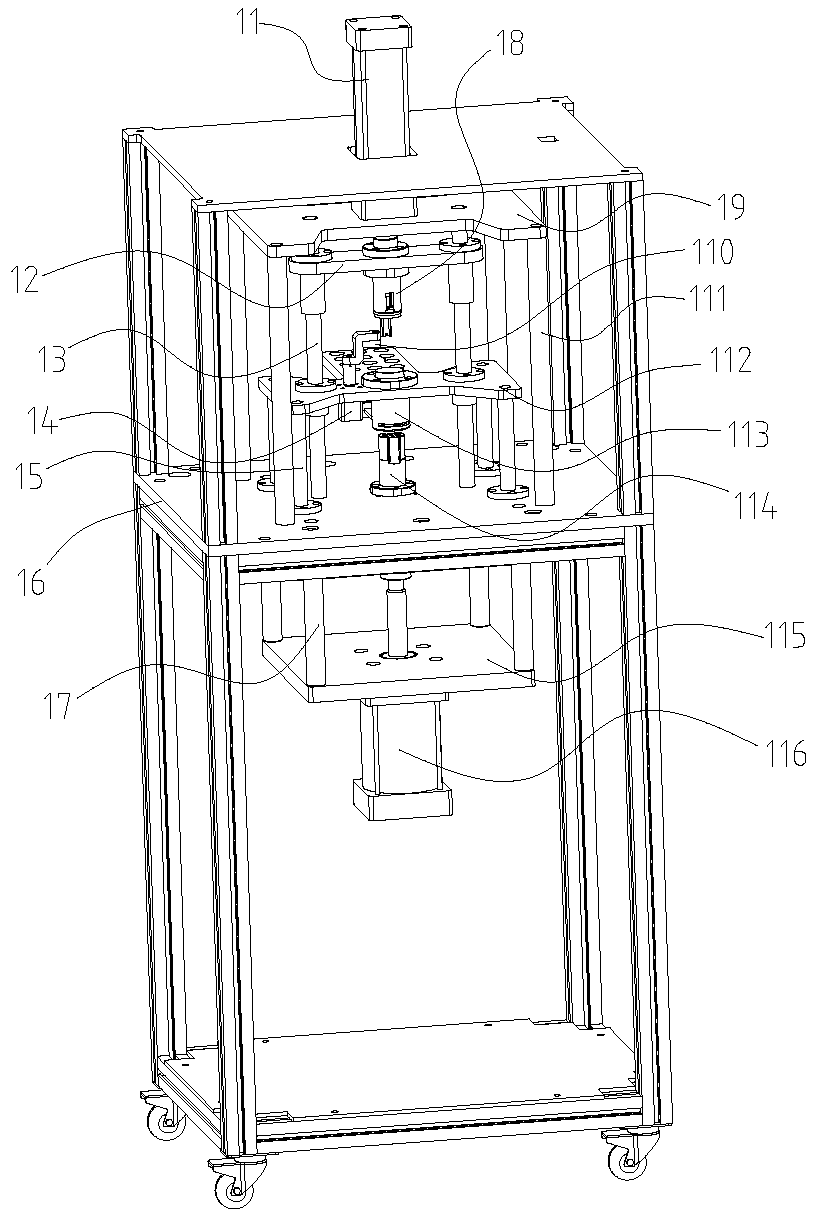

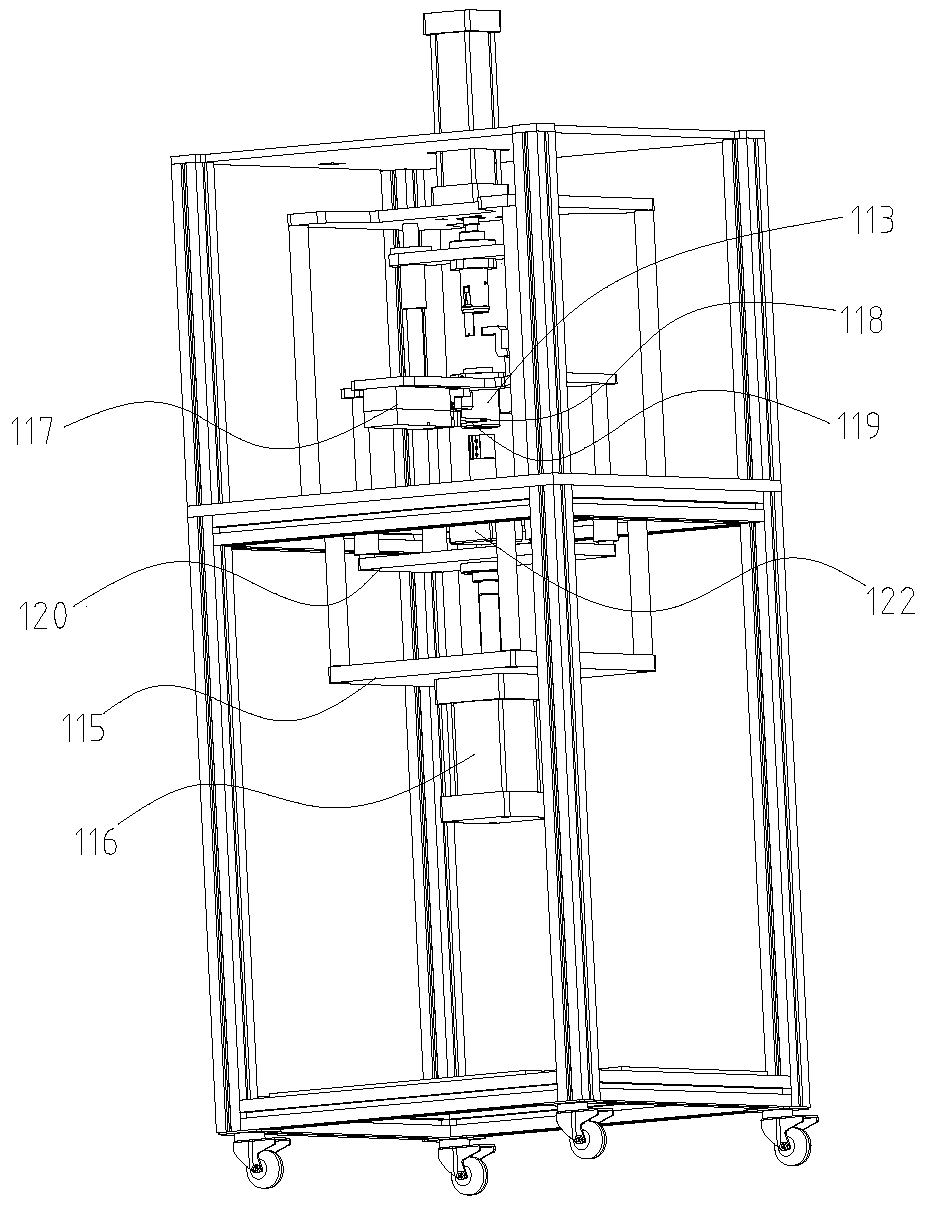

[0040] like figure 2 , 3 As shown, the magnetic tile assembly precision assembly machine 1 includes a frame, a bottom plate located in the middle of the frame, a carbon brush holder positioning mold, an iron shell positioning mold and a magnetic tile positioning mold. Above the mold, the magnetic tile positioning mold is located below the iron shell positioning mold. The carbon brush holder positioning mold includes a first frame body, a first cylinder 11 and a carbon brush holder installation frame 18 connected with the telescopic rod of the first cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com