Automatic jump connector for street lamp

A connector, automatic technology, applied in the direction of connection, connecting device components, circuits, etc., can solve the problems of affecting the use of the connector, general thermal fatigue resistance, reducing the efficiency and service life of the connector, etc., to improve the use of Efficiency, improved strength and stress relaxation resistance, reduced electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

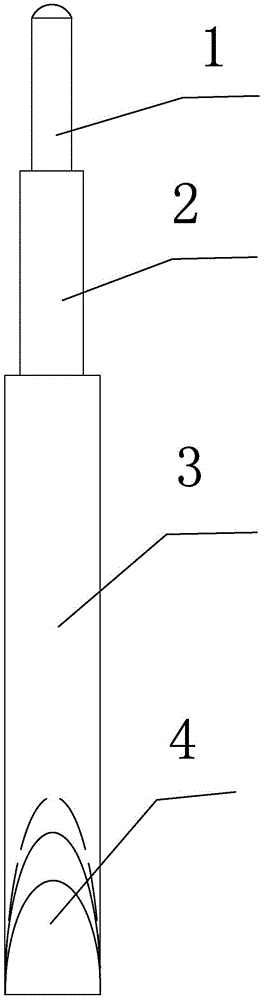

Image

Examples

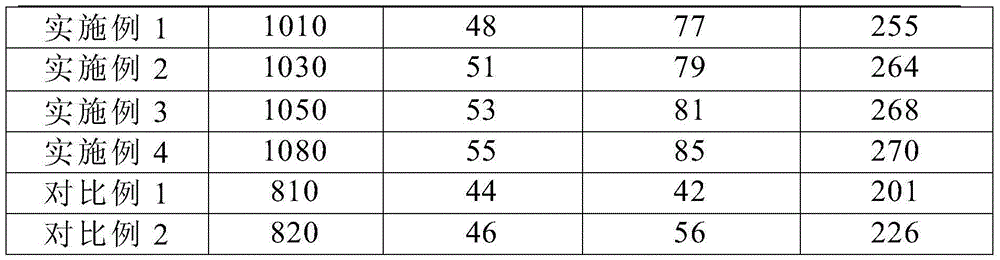

Embodiment 1

[0033] The automatic street lamp jump connector of this embodiment includes a ceramic filling part and a metal layer arranged on the outer layer of the ceramic filling part. The metal layer is a tin-phosphorus bronze alloy layer. The composition and weight percentage of the tin-phosphorus bronze alloy layer are: Zn: 2.7%, Sn: 4.5%, P: 0.01%, Fe: 0.05%, Ni: 0.5-1%, Si: 0.05%, rare earth elements: 0.5%, Pb<0.02%, Al<0.002%, Sb< 0.002%, Bi<0.002%, the remainder is Cu and unavoidable impurity elements, and the rare earth elements are composed of Ce and Sc in a mass ratio of 1.5:1.

[0034] The ceramic filling part is made of silicon carbide ceramic as the main body and at least part of the outer layer of the main body is a silicon nitride ceramic surface layer (that is, there is a silicon nitride ceramic surface layer on a certain area or several areas or the entire surface of the main body surface). The surface roughness of the part is 0.2-2 microns.

Embodiment 2

[0036] The automatic street lamp jump connector of this embodiment includes a ceramic filling part and a metal layer arranged on the outer layer of the ceramic filling part. The metal layer is a tin-phosphorus bronze alloy layer. The composition and weight percentage of the tin-phosphorus bronze alloy layer are: Zn: 3.3%, Sn: 3.5%, P: 0.03%, Fe: 0.01%, Ni: 1%, Si: 0.05%, rare earth elements: 0.5%, Pb<0.02%, Al<0.002%, Sb<0.002% , Bi<0.002%, the balance is Cu and unavoidable impurity elements, wherein the rare earth elements described in tin phosphor bronze consist of Ce and Sc in a mass ratio of 1.3:1.

[0037] The ceramic filling part is made of silicon carbide ceramic as the main body and at least part of the outer layer of the main body is a silicon nitride ceramic surface layer (that is, there is a silicon nitride ceramic surface layer on a certain area or several areas or the entire surface of the main body surface). The surface roughness of the part is 0.2-2 microns.

[0038...

Embodiment 3

[0040] The automatic street lamp jump connector of this embodiment includes a ceramic filling part and a metal layer arranged on the outer layer of the ceramic filling part. The metal layer is a tin-phosphorus bronze alloy layer. The composition and weight percentage of the tin-phosphorus bronze alloy layer are: Zn: 2.8%, Sn: 4.2%, P: 0.015%, Fe: 0.04%, Ni: 0.6%, Si: 0.08%, rare earth elements: 0.2%, Pb<0.02%, Al<0.002%, Sb<0.002% , Bi<0.002%, the balance is Cu and unavoidable impurity elements, and the rare earth elements are composed of Ce and Sc in a mass ratio of 1.4:1.

[0041] The ceramic filling part is made of silicon carbide ceramic as the main body and at least part of the outer layer of the main body is a silicon nitride ceramic surface layer (that is, there is a silicon nitride ceramic surface layer on a certain area or several areas or the entire surface of the main body surface). The surface roughness of the part is 0.2-2 microns.

[0042] The ceramic filling part in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com