Composite aluminum-air battery system

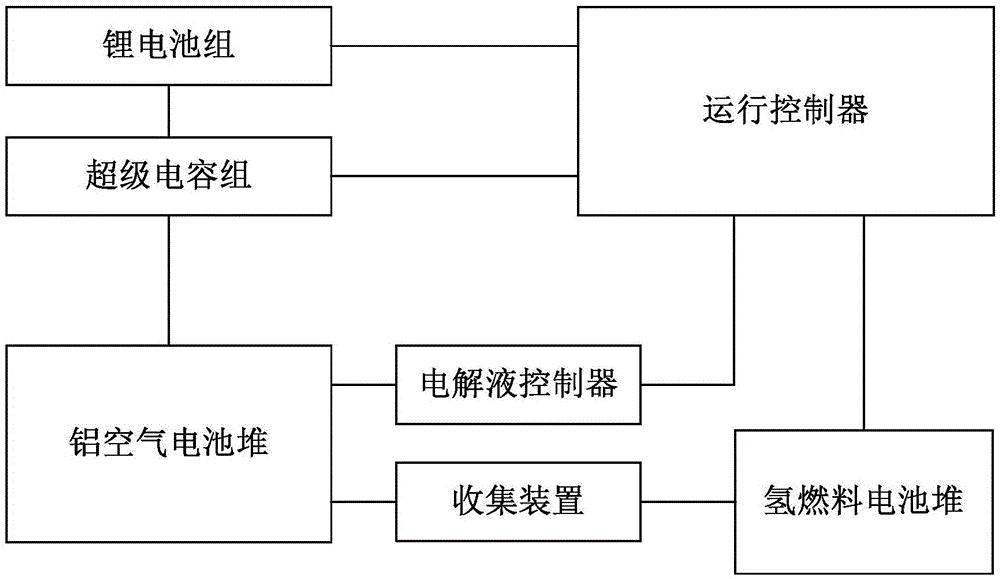

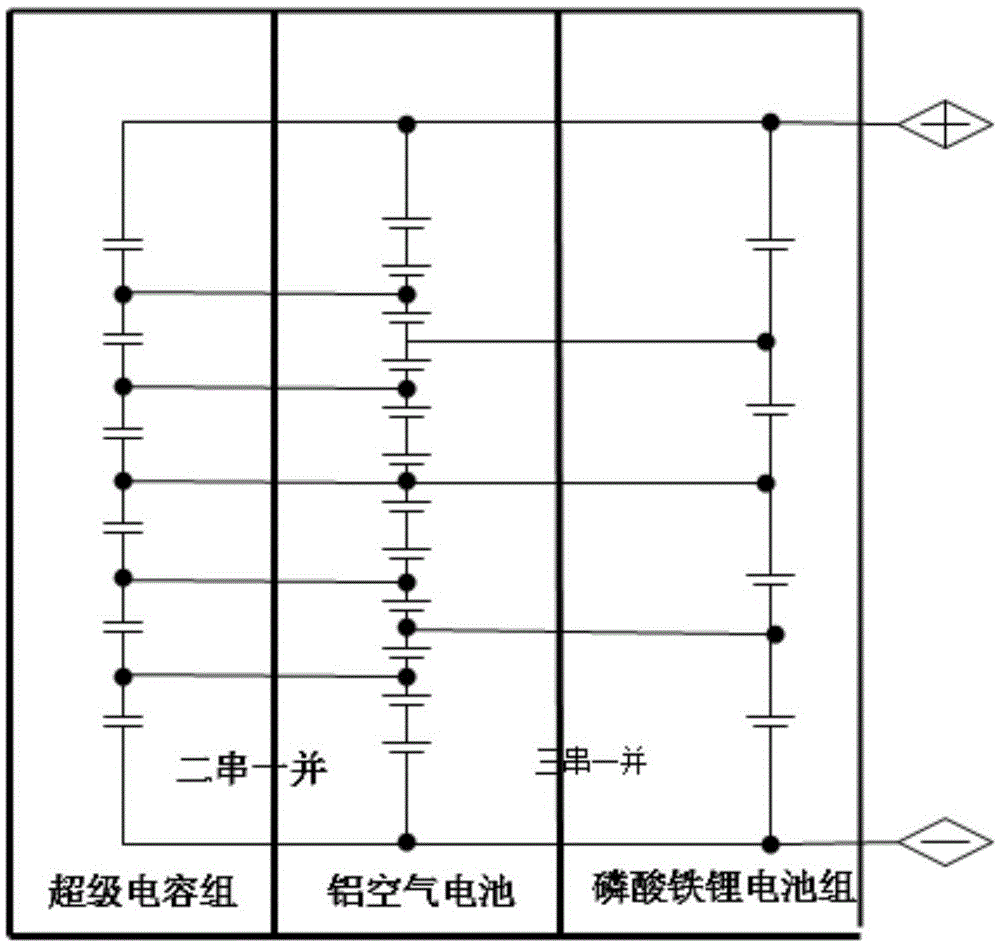

An aluminum-air battery, composite technology, applied in the directions of hybrid batteries, fuel cells, fuel cell additives, etc., can solve the problems of difficulty in meeting the application requirements of electric vehicles, self-corrosion hydrogen evolution, low power density, and low energy utilization rate, etc. Achieve the effect of high cost performance, good environmental performance and high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

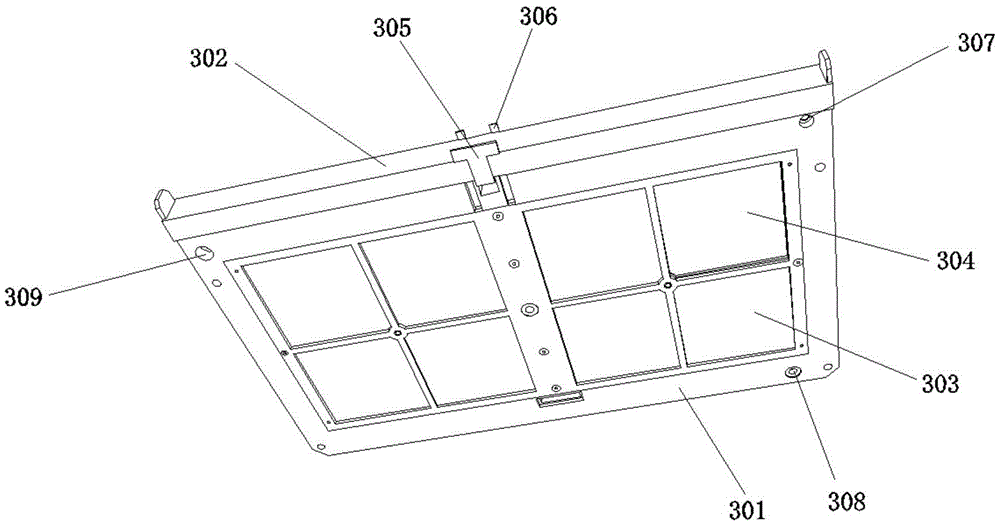

[0043] see Figure 4Embodiment 1 provided for the present invention. The aluminum-air battery stack 401 is composed of 12 pieces of aluminum-air battery cells superimposed and assembled. The platform voltage is 13.2 volts. The initial storage capacity of each single aluminum-air battery is 2.2Kwh, and the total storage capacity of 12 pieces reaches 26Kwh.

[0044] When the electrolyte in the aluminum-air battery stack 401 is in operation, the electrolyte controller 403 is used for regular circulation. There are various sensors and solenoid valves in the electrolyte controller 403. At the same time, according to the operating state, the electric pump is instructed to control the liquid level, liquid temperature, start-up liquid injection, shutdown liquid return, etc., so that the aluminum-air battery stack 401 can be stable for a long time under the control of the electrolyte controller 403 run.

[0045] The aluminum-air battery stack 401 is sealed with a sealing cover, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com