Preparation method for modified diaphragm for lithium-sulfur battery, modified diaphragm and lithium-sulfur battery adopting multiple layers of modified diaphragms

A lithium-sulfur battery and diaphragm technology, applied in the field of electrochemistry, can solve the problems of high price, unfavorable large-scale production, and high cost, and achieve the effects of reducing battery cost, facilitating large-scale production, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

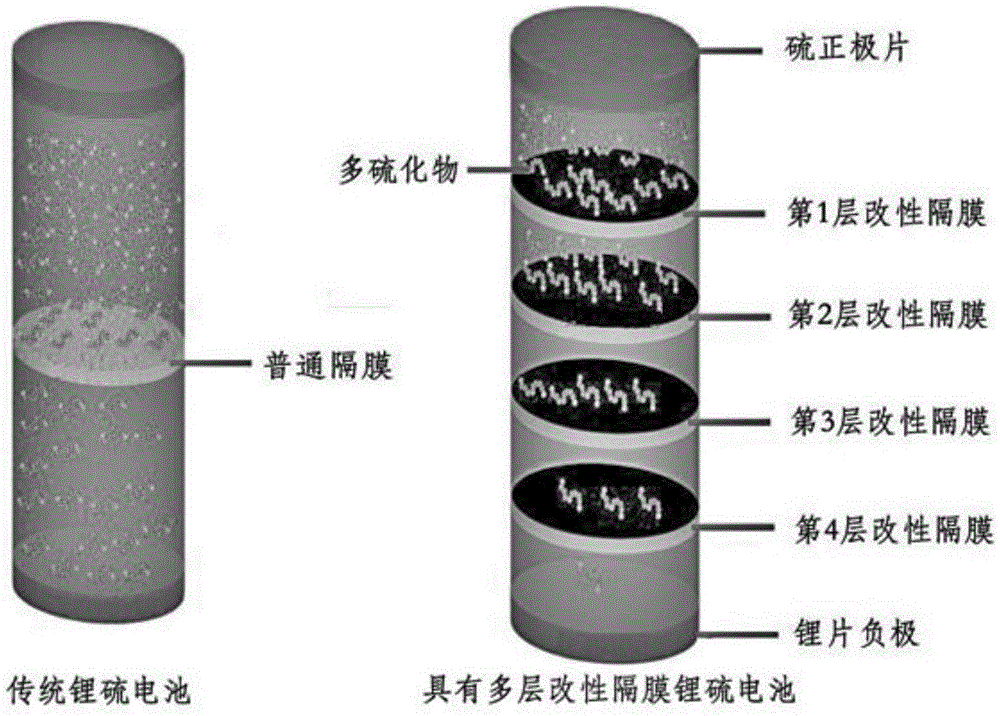

[0045] A preparation method of a modified diaphragm for lithium-sulfur batteries of the present invention, a modified diaphragm and an embodiment of a lithium-sulfur battery having the modified diaphragm:

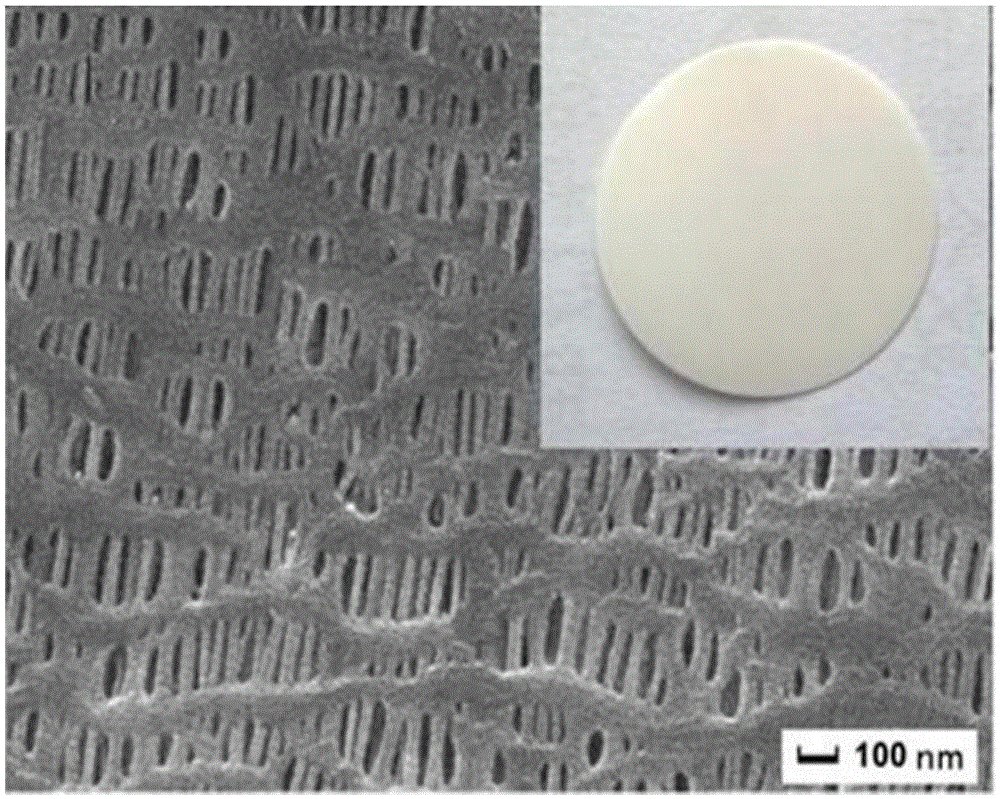

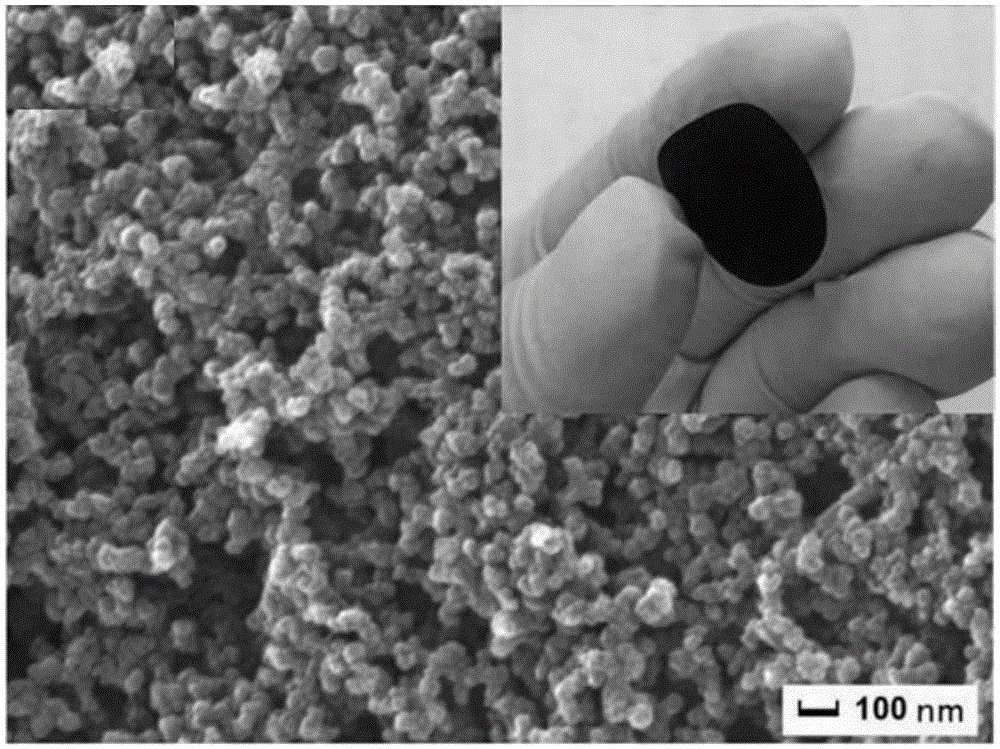

[0046] Preparation of modified diaphragm: Ketjen black (EC600JD) and polyvinylidene fluoride were uniformly mixed at a mass ratio of 1.5:1, and dispersed in N-methylpyrrolidone solvent. Mechanically stirred for 12 hours to obtain a uniformly dispersed coating material. The uniformly dispersed slurry was coated on the surface of the polypropylene diaphragm by doctor blade coating. The coated separator was put into a vacuum drying oven, and dried at 50° C. for 6 hours to obtain a modified separator.

[0047] Lithium-sulfur battery assembly: the carbon-sulfur composite material is used to prepare the sulfur positive electrode, the metal lithium sheet is used as the negative electrode, and a layer of modified diaphragm prepared in the above steps is assembled into a button bat...

Embodiment 2

[0051] A preparation method of a modified separator for lithium-sulfur batteries of the present invention, a modified separator and an embodiment of a lithium-sulfur battery having multiple layers of the modified separator:

[0052] Preparation of modified diaphragm: Ketjen black (EC600JD) and polyvinylidene fluoride were uniformly mixed at a mass ratio of 1.5:1, and dispersed in N-methylpyrrolidone solvent. Mechanically stirred for 12 hours to obtain a uniformly dispersed coating material. The uniformly dispersed slurry was coated on the surface of the polypropylene diaphragm by doctor blade coating. The coated separator was put into a vacuum drying oven, and dried at 50° C. for 6 hours to obtain a modified separator.

[0053] Lithium-sulfur battery assembly: the carbon-sulfur composite material is used to prepare the sulfur positive electrode, the metal lithium sheet is used as the negative electrode, and two layers of the modified diaphragm prepared in the above steps are ...

Embodiment 3

[0056] A preparation method of a modified separator for lithium-sulfur batteries of the present invention, a modified separator and an embodiment of a lithium-sulfur battery having multiple layers of the modified separator:

[0057] Preparation of modified diaphragm: Ketjen black (EC600JD) and polyvinylidene fluoride were uniformly mixed at a mass ratio of 1.5:1, and dispersed in N-methylpyrrolidone solvent. Mechanically stirred for 12 hours to obtain a uniformly dispersed coating material. The uniformly dispersed slurry was coated on the surface of the polypropylene diaphragm by doctor blade coating. The coated separator was put into a vacuum drying oven, and dried at 50° C. for 6 hours to obtain a modified separator.

[0058] Lithium-sulfur battery assembly: the carbon-sulfur composite material is used to prepare the sulfur positive electrode, the metal lithium sheet is used as the negative electrode, and the three-layer modified diaphragm prepared in the above steps is ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com