Remote-control based numerically-controlled machine tool safety system allowing direct unlocking

A security system and technology of CNC machine tools, applied in the field of CNC machine tools, can solve problems such as large safety risks, lack of prevention of misoperation, inability to self-support listing misoperation, etc., to achieve the effect of preventing misoperation and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

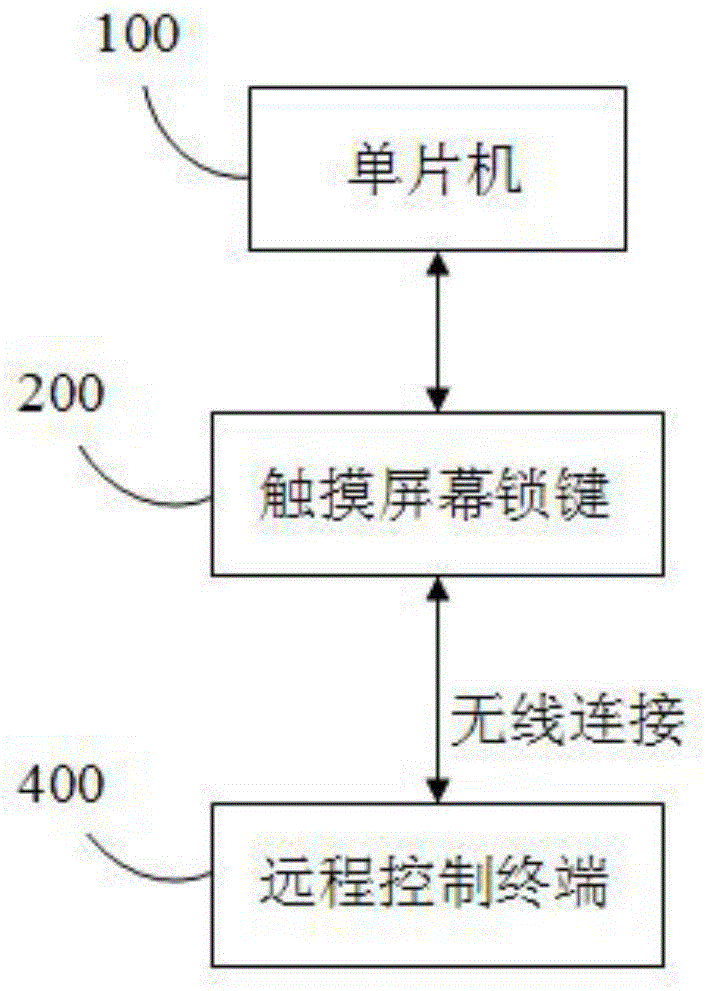

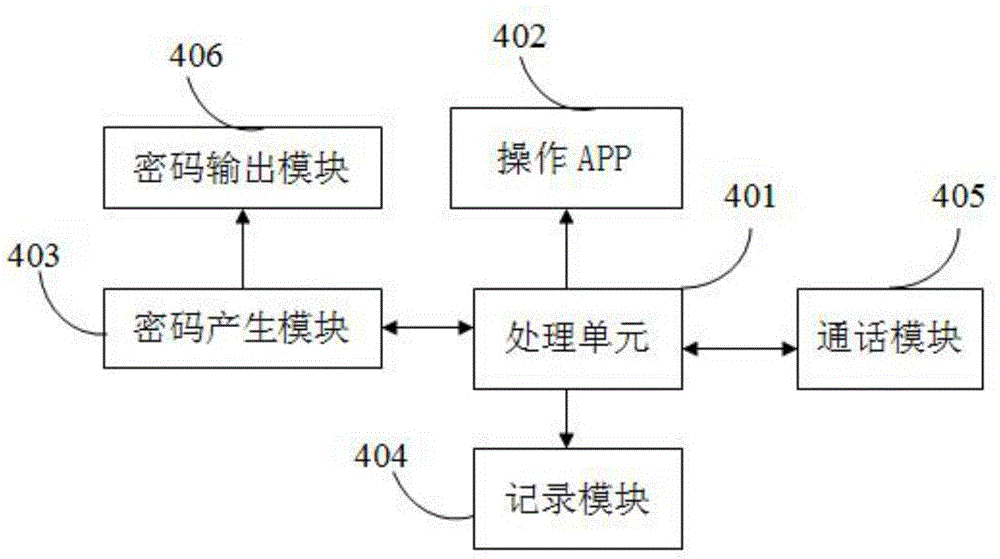

[0034] Such as figure 1 , figure 2 with image 3As shown, a CNC machine tool safety system based on remote control that can be directly unlocked includes a single-chip microcomputer 100 for data processing and information transmission to the key lock security system; touch screen lock key 200 for displaying the key lock security system status information, obtain the trigger signal of the operator’s touch screen operation, judge the content of the signal and make a corresponding response, obtain the lock request, make the screen enter the locked state, send an unlock request, obtain the unlock password, enter the unlock password, and unlock the screen. lock state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com