A digital inkjet printing method

A printing method, digital inkjet technology, applied in the direction of dyeing method, surface/boundary effect, instruments, etc., can solve the problem of general anti-seepage effect, etc., to achieve the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

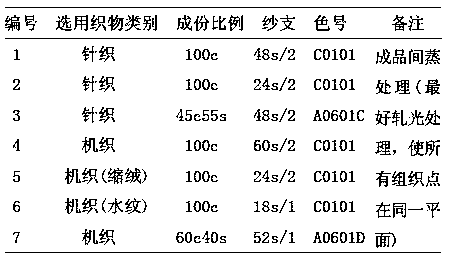

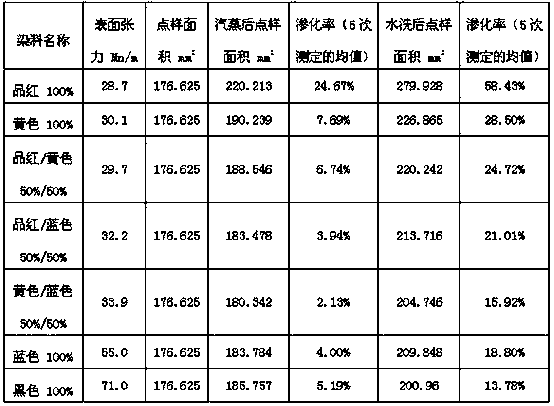

Embodiment 1

[0011] A digital inkjet printing method, including the following steps: measurement of fabric bleeding rate, measurement of dye surface tension, and setting the piezoelectric pressure of the print nozzle according to the selected fabric bleeding rate and the selected dye surface tension value Control the amount of ink jetting of the print nozzle, inkjet printing, post-press drying, steaming, washing and drying. The specific measurement of the fabric penetration rate is as follows: draw the dots by computer, use several pieces of the same fabric sample with 20 dots each, each dot diameter is a standard value, and then print the pattern on the fabric by a digital printing machine; After drying at room temperature, they are processed separately. The area of the ink dots in the spot sample can be obtained through image analysis software such as image-pro or CPAS, and the average area value of the 20 ink spots is used as the evaluation index of the degree of bleeding; = (Spot area...

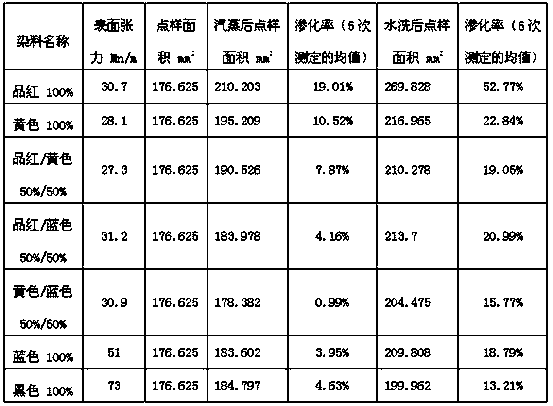

Embodiment 2

[0036] The difference from Example 1 is that the fabric is pretreated before the measurement of the permeation rate of the fabric. The weight fraction of each component of the pretreatment liquid is: 2% paste A-9, 2% SW-MN -08, 3.5% glycerin, 4.5% urea, 10% sodium sulfate, 0.4% weak oxidant, 0.1% tartaric acid and 0.5% calcium carbonate powder; the paste A-9, SW-MN- The preparation steps of 08 are: Weigh the pastes A-9 and SW-MN-08, while keeping stirring, add the weighed pastes A-9 and SW-MN-08 to the soft water, and then Continue to stir until it is uniform; the preparation steps of the pretreatment liquid are: calculate the amount of urea required according to the amount of the treatment liquid, put it into warm water, then add glycerin, sodium sulfate and oxidant, stir until it is completely dissolved and the amount is gradually Add the required paste and keep stirring until the paste swells and there are no clumpy particles. During the process, the temperature of the pretr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com