Electromagnetic iron plate of electronic jacquard of narrow-width loom

An electronic jacquard and electromagnet plate technology, which is applied in the fields of jacquard machines, textiles, textiles and papermaking, etc., can solve the problem of errors in the bending angle of the sheet metal parts of the electromagnet head and the position of the inlaid nut, and the uneven position of the working end surface of the electromagnet Problems such as unevenness, stability, and poor consistency can be solved to achieve stable assembly effects, improve efficiency, and reduce the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

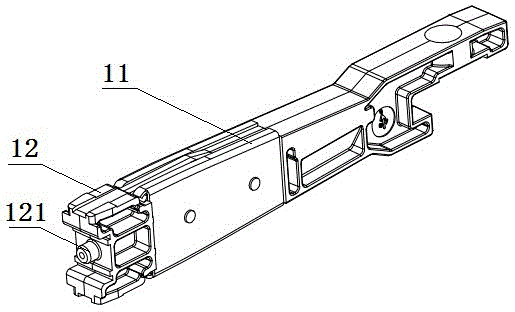

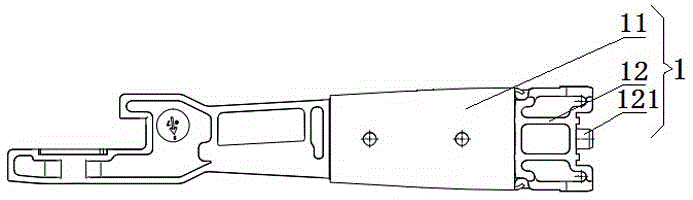

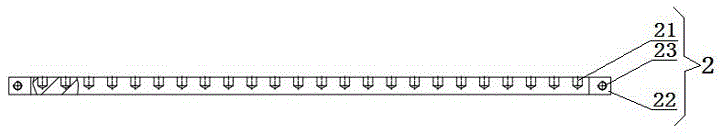

[0022] refer to Figure 1 to Figure 4 As shown, a narrow-width loom electronic jacquard faucet electromagnet board includes a PCB board 3, an electromagnet 1 and a copper strip 2 arranged on the PCB board 3, the electromagnet 1 includes an electromagnet body 11, and the electromagnet 1 includes an electromagnet body 11. One end of the electromagnet main body 11 is fixedly connected with a connecting piece 12, and the outer end surface of the connecting piece 12 is provided with a raised pin 121, and the copper bar 2 is provided with a limiting hole 21 that snaps and fits with the pin 121, In this embodiment, each copper strip 2 is provided with a row of equally spaced limiting holes 21 .

[0023] refer to Figure 5 and Image 6 As shown, the PCB board 3 is fixed on an aluminum base plate 4 by nuts and flat washers 8, the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com