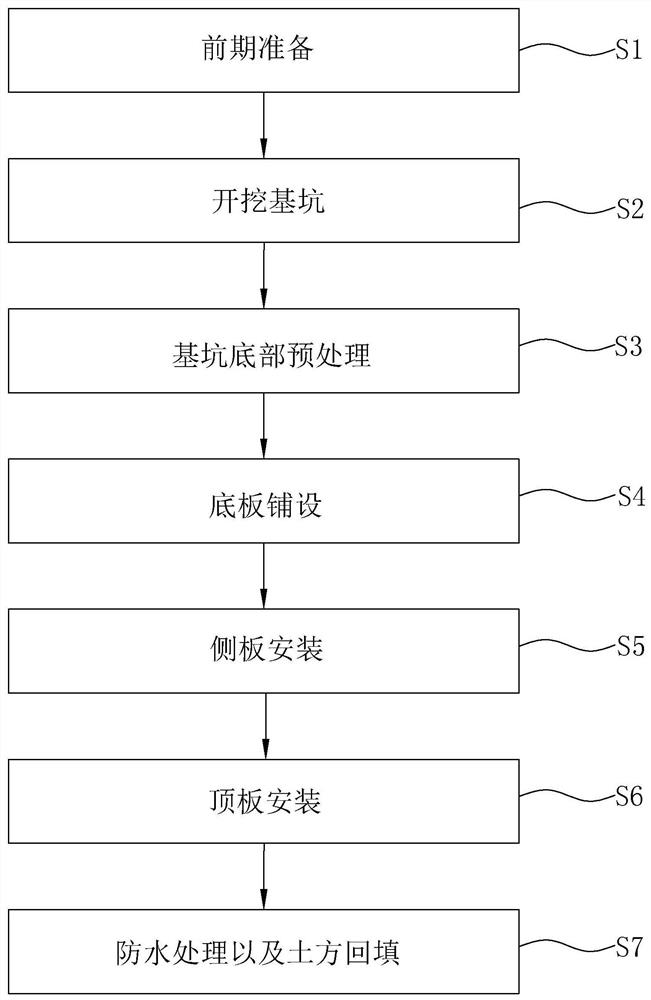

A pipe corridor passage and its construction method

A construction method and channel technology, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of inconvenient transportation and large volume of pipe gallery passages, and achieve the effects of convenient transportation, saving construction time, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

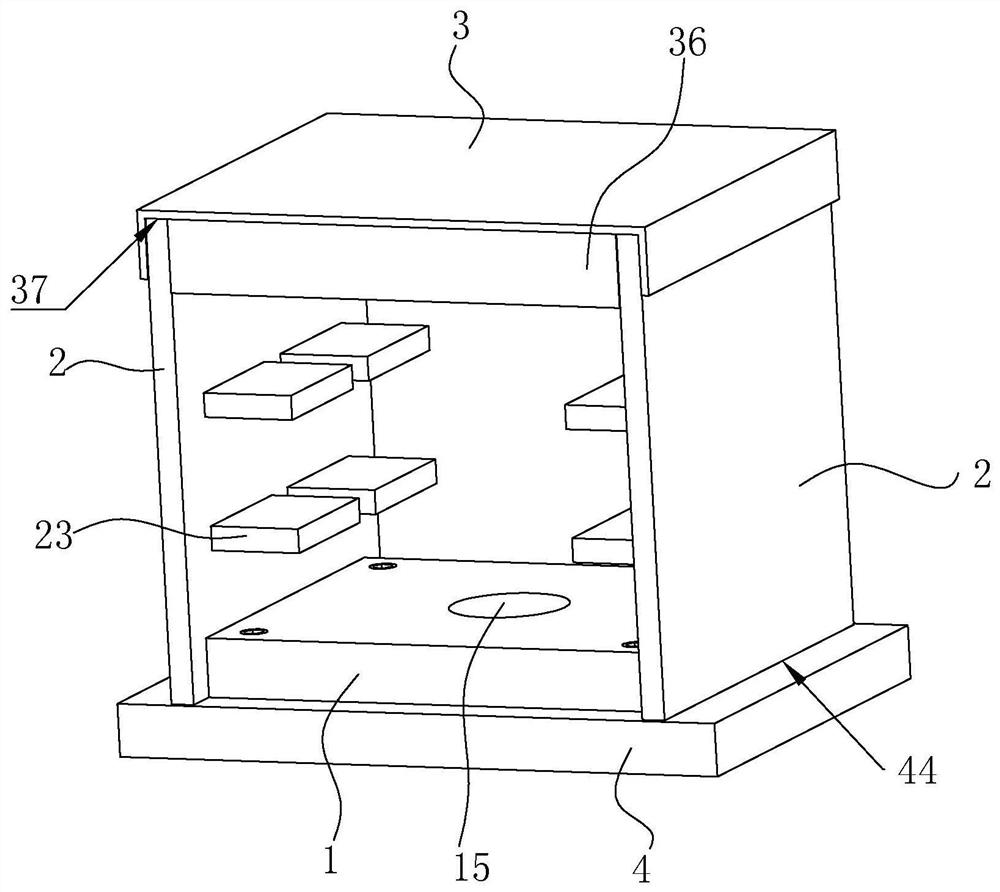

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

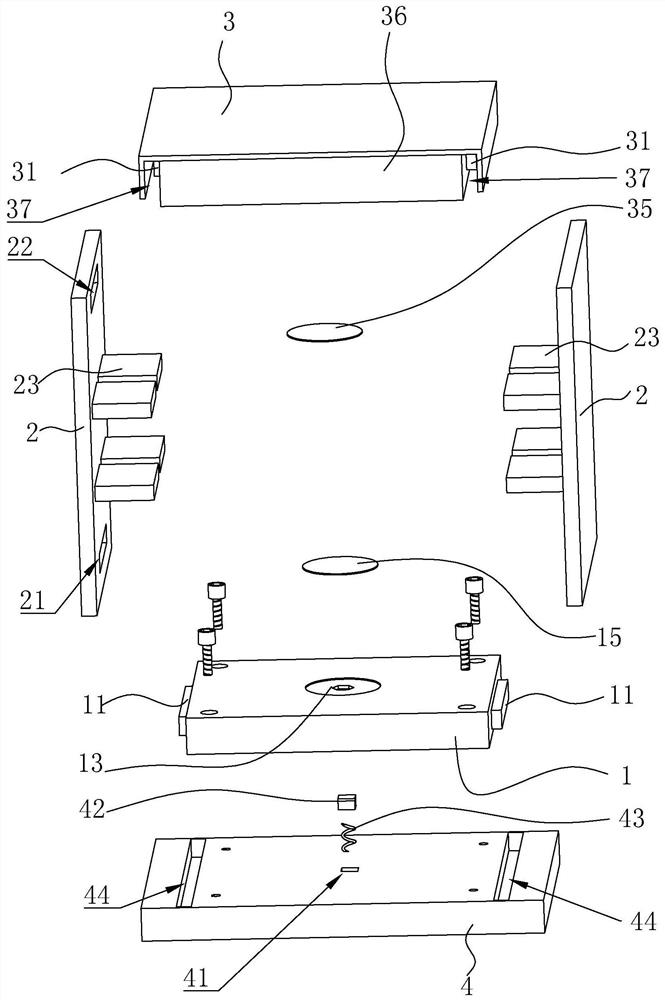

[0052] refer to figure 2 , a pipe gallery passage includes a bottom plate 1, a side plate 2 and a top plate 3, all of which are made of reinforced concrete, and the number of side plates 2 is two. After the bottom plate 1, the side plate 2 and the top plate 3 are installed, they form a rectangular parallelepiped cylindrical shape, and the inside thereof is used for installing pipelines and pipelines.

[0053] refer to image 3 A side wall of the side plate 2 is provided with a first groove 21 and a second groove 22, the length of the first groove 21 and the second groove 22 are the same, and the first groove 21 is located at the edge of the second groove 22. Below, the opposite lengths of the first groove 21 and the second groove 22 are consistent with the length direction of the side plate 2 . The side plate 2 is provided with the first groove 21 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com