Diaphragm type gas meter and movement thereof

A gas meter and movement technology, which is applied in the direction of measuring devices, instruments, liquid/fluid solid measurement, etc., can solve the problems of low assembly efficiency, poor sealing and reliability of the movement, and achieve quick and easy assembly, improved sealing performance, Strong and reliable sealing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

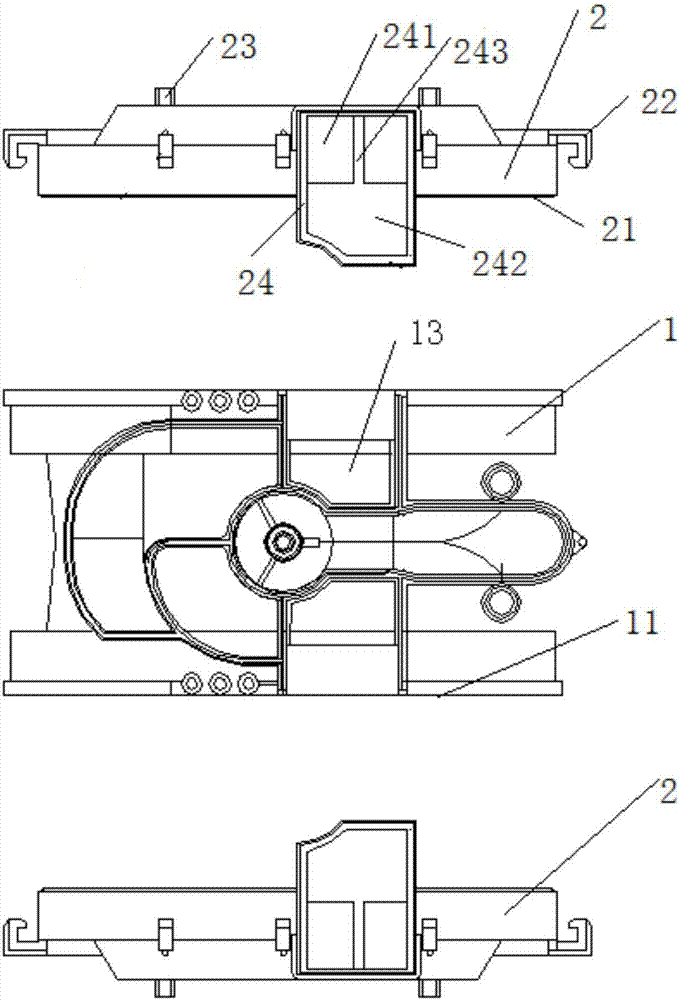

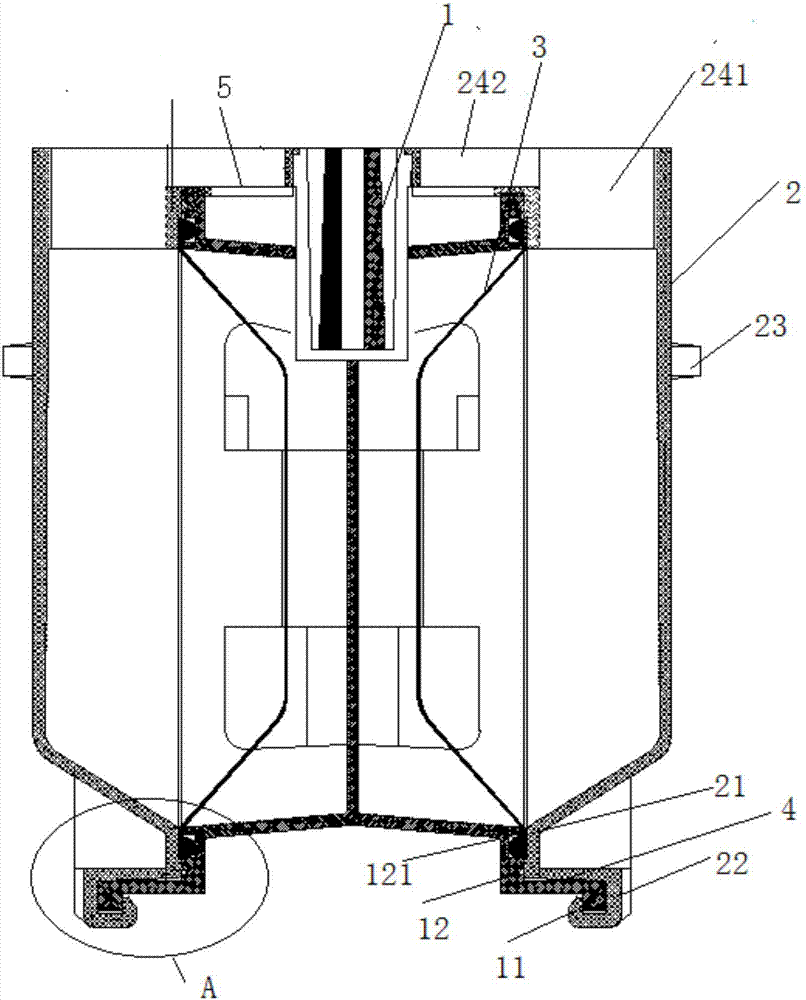

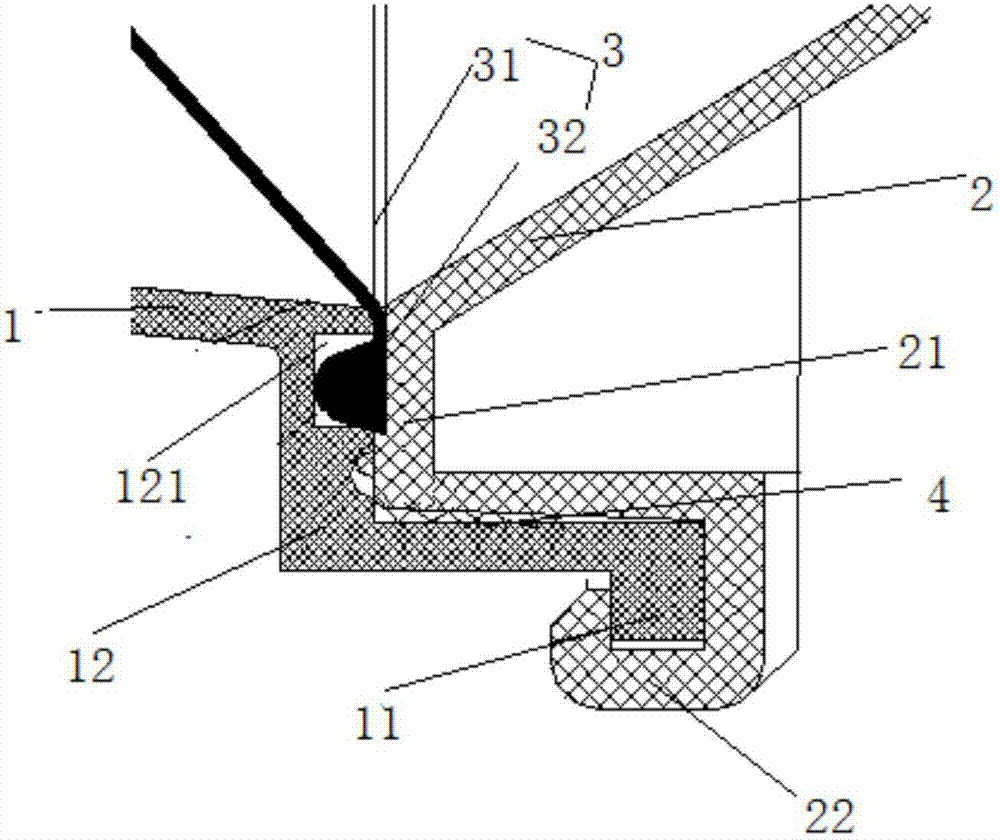

[0035] Such as figure 1 with figure 2 As shown, the gas meter movement includes a movement body 1 oppositely provided with a port 11; two side cover plates 2 are provided and are respectively sealed and connected to the port 11 of the movement body 1; The chip assembly 3 is arranged between the core body 1 and the side cover 2, and is used to divide the metering chamber formed by the core body 1 and the side cover 2 into two chambers; the core body The inner side of the port 11 of 1 is formed with an annular platform 12 for installing the diaphragm assembly 3, and the side cover 2 is formed with an embedded port 11 and the annular platform 12 to compress the diaphragm assembly 3 The annular boss 21, the first sealing surface 4 is formed between the annular boss 21 and the movement wall between the annular platform 12 and the port 11; the side cover 2 and the port 11 are fixed by a snap-fit structure .

[0036]In the above structure, the annular boss 21 on the side cover ...

Embodiment 2

[0047] A diaphragm gas meter, comprising the gas meter movement described in any one of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com