Installing structure of automobile shifting cover

A technology for installing structure and cover, which is applied to control devices, vehicle parts, transportation and packaging, etc., can solve the problems of unreusable shift cover, inefficient disassembly and assembly, and many assembly processes, and reduces the number of molds. The effect of investment, improving assembly efficiency and simple assembly method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

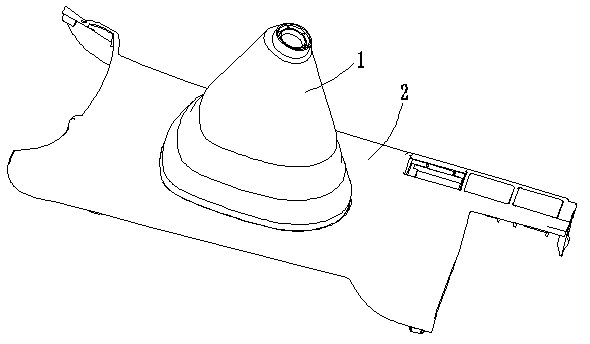

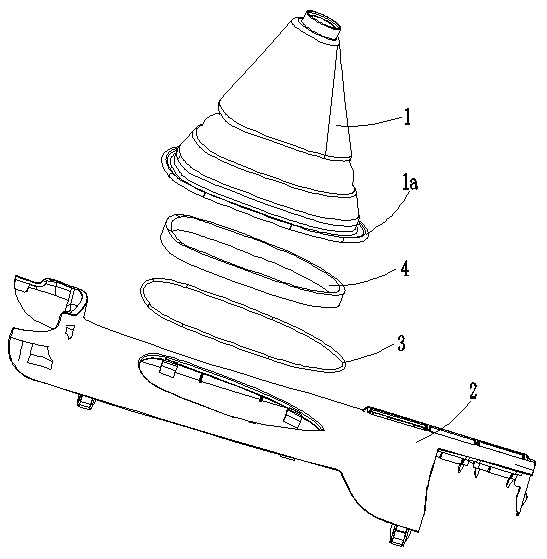

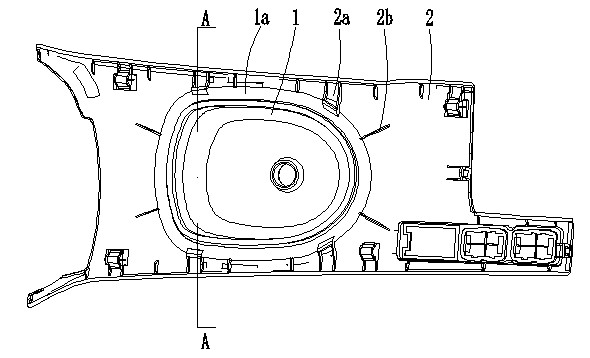

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is made of parts such as shift cover 1, shift panel 2, steel traveler 3 and felt ring 4. Wherein, the shift panel 2 is molded by injection molding, and a via hole is opened in the middle of the shift panel 2, and a set of clamp feet 2a are respectively provided at the left and right ends of the bottom surface of the shift panel 2, and these two sets of clamp feet 2a are separated in the through holes. Left and right sides, and distributed symmetrically. Each set of clamping feet 2a is divided into front and rear two, and each clamping foot 2a is connected with the shift panel 2 as a whole. A locking slot is formed at the root of each locking foot 2a, and the notch of the locking slot faces the through hole in the middle of the shift panel 2 . A pair of baffles 2b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com